Electric turbochargers are revolutionizing the automotive industry by providing a seamless blend of power and efficiency. Unlike traditional turbochargers, electric versions offer instantaneous response and improved fuel economy, making them a vital component in modern vehicles striving for lower emissions and better performance.

The Evolution of Turbocharging Technology

History and Development

Traditional turbochargers have been around since the early 20th century, primarily used to increase engine power by forcing more air into the combustion chamber. Despite their benefits, conventional turbochargers have limitations, including turbo lag—a delay between throttle input and engine response due to the time taken for exhaust gases to spool up the turbo. This sluggishness can hinder performance, especially in smaller engines where responsiveness is crucial.

Over the years, the transition from mechanical to electric turbocharging has been a response to these shortcomings. Electric turbochargers, unlike their predecessors, utilize an electric motor to spin the compressor, providing an immediate boost without waiting for exhaust gases. This advancement not only solves the turbo lag issue but also aligns with the growing demand for efficient and environmentally friendly automotive technologies.

Why Electric Turbochargers?

The primary advantage of electric turbochargers is their ability to eliminate turbo lag. By using an electric motor, these turbochargers provide immediate response, significantly enhancing driving dynamics and performance. This instant power delivery is particularly beneficial in hybrid and smaller displacement engines, where maintaining efficiency without sacrificing power is crucial.

Additionally, electric turbochargers contribute to reduced emissions. By optimizing the combustion process and improving engine efficiency, they help lower fuel consumption. As emissions regulations become increasingly stringent, electric turbochargers are becoming an essential component in meeting these standards while still delivering high performance.

How Electric Turbochargers Work

Basic Mechanics

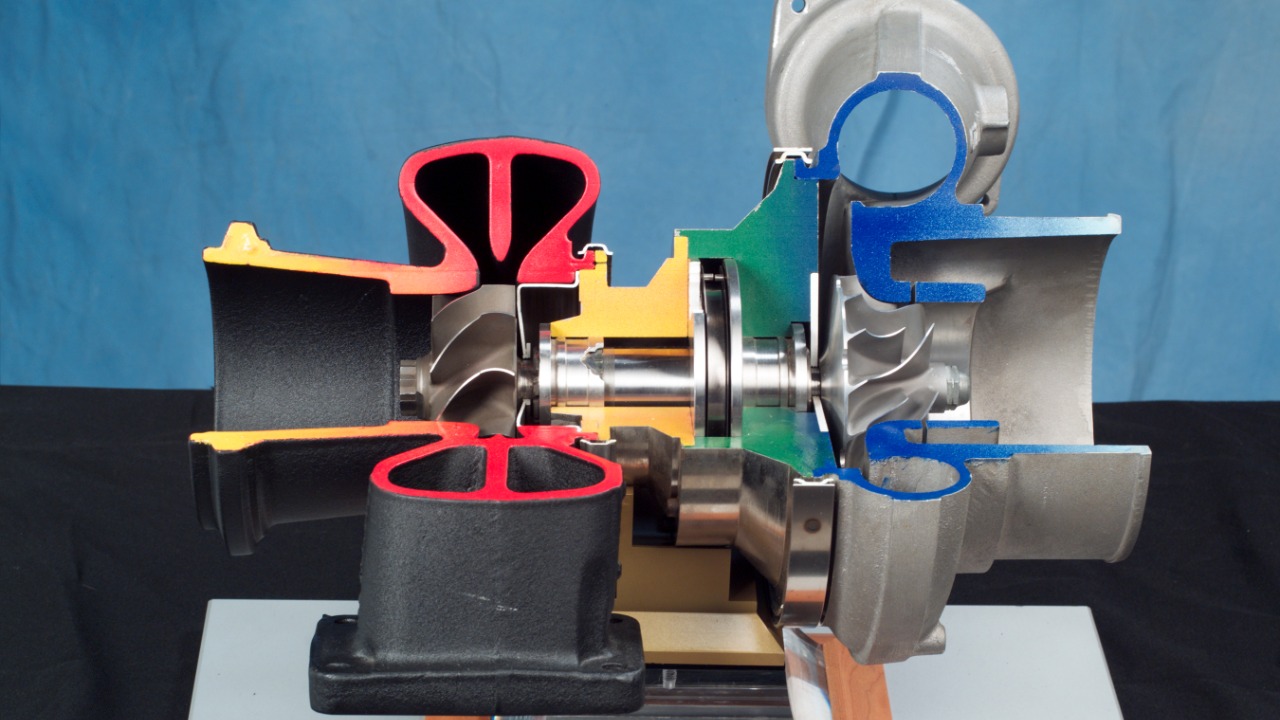

Electric turbochargers are composed of several key components: an electric motor, a compressor, and a turbine. The electric motor drives the compressor, which forces air into the engine, similar to traditional systems. However, because the motor is electrically powered, it can operate independently of exhaust gases, providing boost pressure on demand. This setup ensures that the engine receives a consistent air supply, enhancing overall performance.

The difference between electric and conventional turbochargers lies in the source of power. While traditional models rely on exhaust gases, electric versions draw energy from the vehicle’s electrical system, allowing for more precise control over boost levels. This distinction is crucial in understanding how electric turbochargers can deliver both improved efficiency and performance.

Integration with Hybrid and Electric Vehicles

In hybrid vehicles, electric turbochargers play a pivotal role in optimizing engine performance. They enable smaller, more efficient engines to deliver the power of larger engines without the accompanying fuel consumption. By providing instant torque, they help hybrid vehicles achieve smoother acceleration and better fuel efficiency.

Electric turbochargers also integrate seamlessly with electric vehicle technology. In these setups, they work in tandem with electric motors to enhance overall vehicle efficiency. By optimizing the energy management system, electric turbochargers help maximize the range and performance of electric vehicles, making them a key component in the evolution of sustainable transportation.

Benefits of Electric Turbochargers

Performance Enhancements

One of the most notable benefits of electric turbochargers is the improvement in vehicle performance. By delivering instantaneous torque, they enhance acceleration and responsiveness, offering a more dynamic driving experience. This capability is particularly advantageous in sports cars and performance vehicles, where acceleration and speed are paramount.

In addition to improved acceleration, electric turbochargers increase engine power output without additional fuel consumption. This efficiency allows manufacturers to design smaller, lighter engines that deliver comparable power to larger, less efficient counterparts. As a result, vehicles equipped with electric turbochargers can achieve better fuel economy and reduced emissions without sacrificing performance.

Environmental Impact

The environmental benefits of electric turbochargers are significant. By improving engine efficiency, they contribute to a reduction in carbon emissions and fuel consumption. This improvement is crucial in helping automakers meet global emission standards and regulations, which are becoming increasingly stringent.

Moreover, electric turbochargers support the automotive industry’s shift towards greener technologies. By enabling more efficient and cleaner combustion, they play a vital role in the development of sustainable vehicles. As electric turbocharger technology continues to advance, its potential to reduce the environmental impact of transportation will only grow.

Challenges and Future Prospects

Technical and Engineering Hurdles

Despite their advantages, electric turbochargers face several challenges in widespread adoption. One of the primary hurdles is cost. The sophisticated components and advanced technology required for electric turbochargers make them more expensive than traditional systems. Additionally, integrating them into existing vehicle architectures can be complex, requiring significant engineering efforts.

However, ongoing research and development efforts are focused on overcoming these obstacles. Innovations in materials, design, and manufacturing processes are expected to reduce costs and simplify integration. As these challenges are addressed, electric turbochargers are likely to become a more common feature in a broader range of vehicles.

Future Developments

The future of electric turbocharger technology is promising, with several potential advancements on the horizon. Improvements in battery technology and electrical systems will enable electric turbochargers to deliver even greater performance and efficiency. Additionally, advancements in control systems will allow for more precise management of boost pressure, further enhancing vehicle dynamics.

As the automotive industry continues to evolve, electric turbochargers will play a pivotal role in shaping the future of automotive engineering. Their ability to deliver power, efficiency, and environmental benefits aligns with the industry’s goals of creating sustainable, high-performance vehicles. As technology advances, the impact of electric turbochargers is set to expand beyond the automotive sector, influencing other industries in need of efficiency and performance gains.

Case Studies and Real-World Applications

Automotive Industry Examples

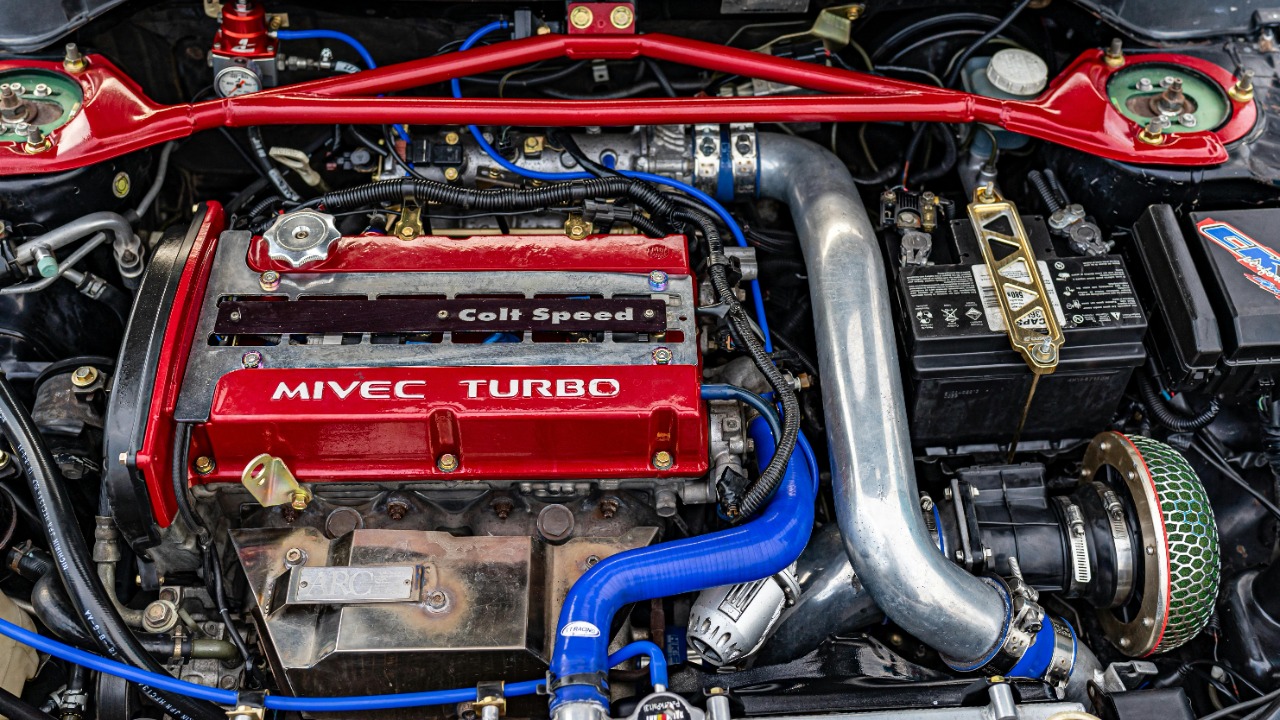

Several car manufacturers are already implementing electric turbochargers in their vehicles. For instance, the 2023 Audi Q7 utilizes an electric turbocharger to enhance performance and efficiency. Consumer feedback indicates that the vehicle offers improved acceleration and a more engaging driving experience, highlighting the benefits of this technology.

Another example is the Mercedes-Benz E-Class, which uses electric turbochargers to deliver impressive power while maintaining excellent fuel economy. These implementations showcase the potential of electric turbochargers to transform vehicle performance and efficiency.

Cross-Industry Impacts

Beyond the automotive industry, electric turbochargers have potential applications in other sectors. In aviation, for example, they could be used to enhance engine performance and reduce fuel consumption, contributing to more sustainable air travel. Similarly, in heavy machinery, electric turbochargers offer the potential to improve efficiency and reduce emissions.

The versatility of electric turbocharger technology makes it an attractive option for industries seeking performance and efficiency gains. As research and development continue, the adoption of electric turbochargers in various sectors is expected to grow, further demonstrating their transformative potential.