The F-15 Eagle fighter jet is renowned for its exceptional speed and maneuverability, largely due to its two Pratt & Whitney F100 engines. These engines, particularly the F100-PW-229 variant, deliver up to 29,000 pounds of thrust each with afterburner, making them some of the most powerful in modern fighter aircraft. This capability is highlighted in a 2024 analysis of global jet propulsion technology, which ranks these engines among the top in the world for their power and efficiency.

Overview of F-15 Engine Selection

The selection process for the F-15’s powerplant in the 1970s was a critical decision that ultimately favored the Pratt & Whitney F100 over competitors like the GE F101. The F100 was chosen for its superior thrust-to-weight ratio and reliability, essential qualities for the F-15’s demanding air superiority roles. The dual-engine configuration of the F-15 not only provides redundancy but also enhances its performance across various missions, including interception and strike operations. This choice reflects a strategic balance between power and reliability, ensuring the F-15’s effectiveness in diverse combat scenarios (Simple Flying). The integration of the F100 series into the F-15 airframe involved several key design features, such as variable stator vanes, which improve efficiency across different flight regimes. This adaptability allows the F-15 to maintain optimal performance whether cruising at high altitudes or engaging in low-level maneuvers. The engine’s design ensures that the F-15 remains a versatile and formidable presence in the skies.

The decision to equip the F-15 with the Pratt & Whitney F100 engines was not only a matter of performance but also of strategic foresight. During the Cold War era, the United States Air Force needed a fighter jet that could outperform Soviet aircraft in terms of speed, agility, and operational range. The F100’s advanced design, which included features like a modular construction for easier maintenance and repair, was a significant factor in its selection. This modularity reduced downtime and increased the aircraft’s availability for missions, a critical advantage in potential conflict scenarios. Additionally, the F100’s ability to operate efficiently in diverse environmental conditions made it a versatile choice for deployment across various theaters of operation, from the cold climates of Europe to the hot deserts of the Middle East.

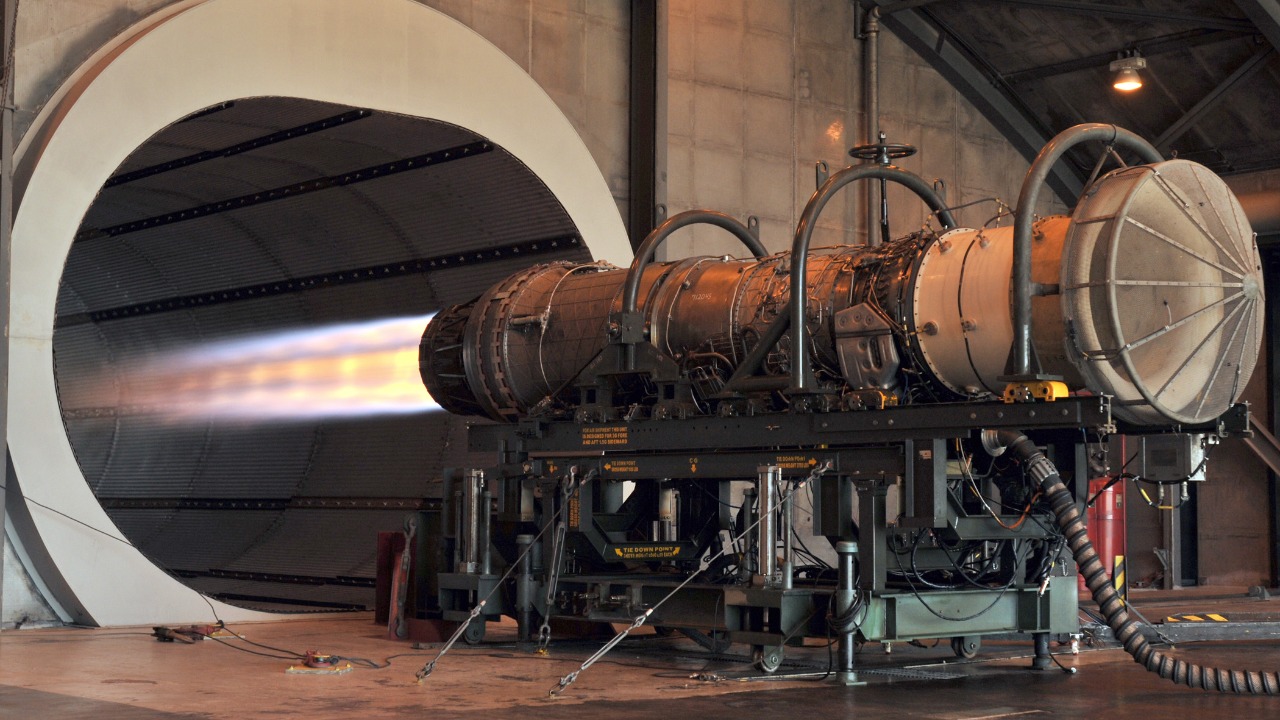

Technical Specifications of the F100 Engine

The baseline F100-PW-100 engine, used in early F-15 models, provides a dry thrust of 14,590 lbf and an afterburner thrust of 23,770 lbf per engine. These specifications laid the groundwork for subsequent upgrades, such as the F100-PW-220 variant. This version increased the afterburner thrust to 23,770 lbf through enhancements in the fan and compressor stages, improving both fuel efficiency and power output (Simple Flying). The most advanced model, the F100-PW-229, offers a remarkable 29,000 lbf of afterburner thrust. This variant incorporates digital engine control, allowing for precise operation during high-G maneuvers. Such advancements ensure that the F-15 can perform at the highest levels of combat readiness, maintaining its edge over potential adversaries.

The F100 engine series has undergone several iterations to enhance its performance and reliability. The F100-PW-220, for instance, introduced improvements in turbine cooling technology, which allowed for higher operating temperatures and, consequently, greater thrust without compromising engine life. This variant also featured an upgraded digital electronic engine control (DEEC) system, which provided more precise throttle management and reduced pilot workload. The DEEC system was a significant leap forward, offering real-time adjustments to optimize performance and fuel efficiency under varying flight conditions. These technological advancements ensured that the F100 engines remained at the forefront of fighter jet propulsion technology.

Performance and Power Analysis

The F100 engines are pivotal in enabling the F-15’s impressive top speed of Mach 2.5 and a service ceiling of 65,000 feet. These capabilities are further enhanced by thrust vectoring potential in later variants, which improves maneuverability during complex aerial engagements. The thrust-to-weight ratio, approximately 8:1 for the F-15C with F100-PW-220 engines, underscores the aircraft’s superiority in acceleration and climb rate (Simple Flying). Fuel consumption is another critical factor, with the F100 series achieving around 1.8 pounds of fuel per pound of thrust per hour in afterburner mode. This balance between endurance and raw power allows the F-15 to sustain prolonged operations without compromising on performance, making it a reliable asset in extended missions.

The F100 engines’ contribution to the F-15’s performance is not limited to raw power. The engines’ sophisticated design includes advanced materials and cooling techniques that allow for sustained high-speed flight and rapid acceleration. This capability is crucial during dogfights, where the ability to quickly change speed and direction can determine the outcome of an engagement. Furthermore, the engines’ robust construction supports high sortie rates, enabling the F-15 to undertake multiple missions with minimal maintenance between flights. This operational readiness is a key factor in the aircraft’s continued use by air forces around the world, even decades after its introduction.

Comparison to Global Fighter Engines

The F100 engines are consistently ranked among the world’s most powerful, a testament to their maximum thrust output and operational efficiency. When compared to competitors like the Eurojet EJ200, which produces 20,250 lbf and is used in the Eurofighter Typhoon, the F100-PW-229’s 29,000 lbf thrust provides a significant advantage in sustained high-thrust operations (Simple Flying). The evolutionary impact of F100 technology is evident in subsequent U.S. engines, such as the F119 used in the F-22 Raptor. These advancements have not only maintained the F-15’s edge in export variants but also influenced the development of future propulsion systems, ensuring that the legacy of the F100 continues to shape the landscape of aerial combat.

In the global context, the F100 engines have set a benchmark for fighter jet propulsion systems. Their influence extends beyond the F-15, as seen in the development of the F119 engine for the F-22 Raptor, which incorporates lessons learned from the F100’s service history. The F100’s design philosophy, emphasizing a balance between power, efficiency, and reliability, has been adopted by other engine manufacturers aiming to compete in the high-performance military aviation market. For instance, the Russian AL-31F engine, used in the Sukhoi Su-27, mirrors some of the F100’s design principles, such as modularity and advanced cooling systems, highlighting the F100’s role as a pioneer in modern jet engine technology.