Physicists have turned a long-standing imaging workhorse into a kind of nanoscale chisel, using a razor-precise ion beam to carve intricate three-dimensional structures directly out of single crystals. Instead of stacking thin films or relying on slow, layer-by-layer printing, they are now cutting spirals, bridges, and coils straight from solid matter with near-atomic control. The result is a new class of tiny devices where geometry is not an afterthought but a powerful design parameter that can reshape how electricity and magnetism behave.

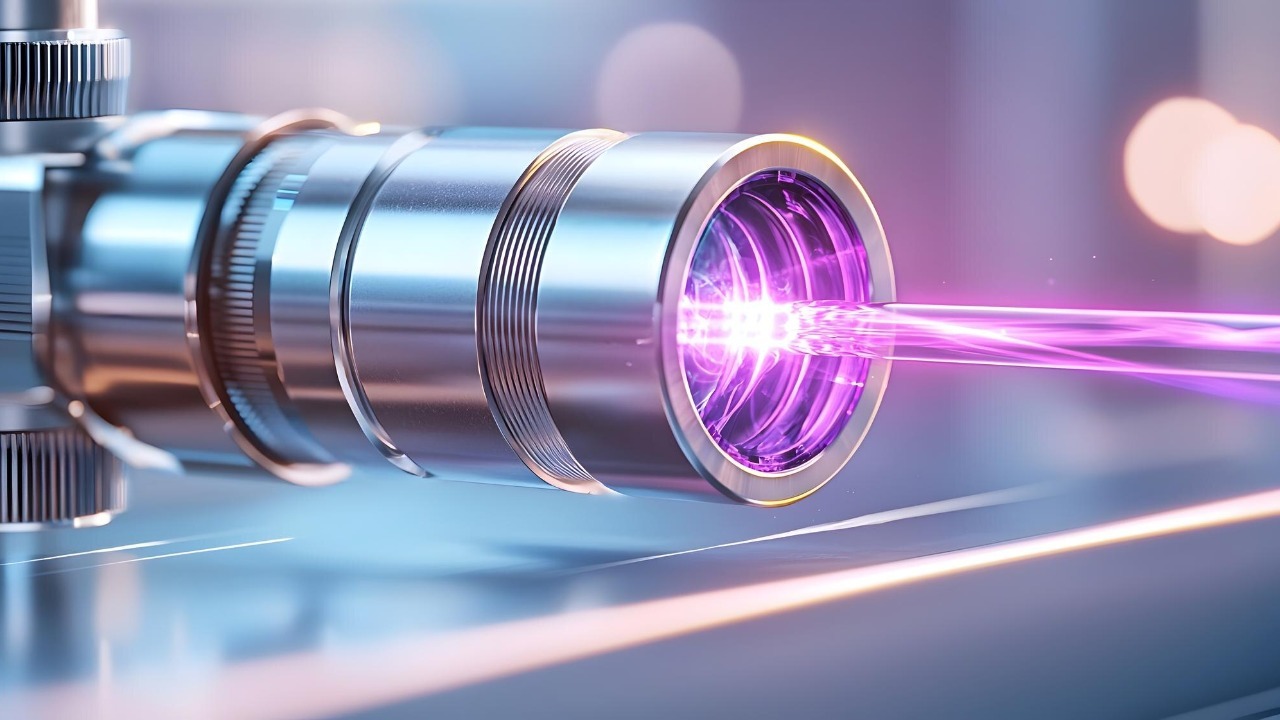

At the heart of this advance is a focused ion beam, a tool that once mainly served to polish and inspect samples but is now being pushed into full-fledged fabrication. By steering this beam through a crystal like a sculptor’s blade, researchers can twist and tilt the material into shapes that were previously impossible at such small scales. Those wild 3D forms are not just visually striking, they are already revealing new physics and hinting at future electronics that exploit shape as deliberately as they exploit composition.

From flat films to true 3D nanosculpting

For decades, most nanotechnology has been effectively two-dimensional, built as stacks of flat layers patterned with lithography and etching. That approach has delivered everything from smartphone processors to quantum dots, but it struggles when engineers need fully three-dimensional architectures with smooth curves or overhanging features. Focused ion beams were present in many labs, yet they were typically used to cut cross-sections or tidy up samples, not to create elaborate 3D devices from scratch.

The new work changes that by treating the beam as a sculpting tool that can mill a single crystal into almost any desired shape. In the latest experiments, Scientists from the RIKEN Center for Emergent colleagues use the beam to hollow, tilt, and twist a single-crystalline material, effectively machining it into a free-standing 3D device while preserving its internal order.

Helical devices carved from a magnetic Weyl semimetal

The most striking demonstration so far involves a magnetic Weyl semimetal, a material whose electrons behave as if they are massless particles tied to the crystal’s symmetry. Researchers start with a single-crystalline sample of Co3Sn2S2 and then carve it into tiny helices, turning a blocky crystal into a nanoscale spiral staircase. According to the nanosculpted device report, the emergent properties of this material are tightly linked to the symmetries of its atomic, spin, and charge order, so reshaping it in three dimensions directly rewires its behavior.

The resulting Abstract describes how these 3D helices exhibit responses that depend on the handedness of the structure, a clear sign that the chiral device geometry is acting as a new control knob. In other words, the same Co3Sn2S2 crystal behaves differently when it is straight versus when it is twisted into a helix, even though its chemical composition is unchanged. That is a powerful proof of concept for using shape as a design variable in topological materials, not just as a mechanical constraint.

The focused ion beam technique as a nanoscale sculpting tool

At the core of this progress is a specific technique that turns a focused ion beam into a controllable carving instrument rather than a blunt cutter. By tuning the beam current, dwell time, and scan pattern, the team can remove material layer by layer while keeping the remaining crystal intact and electrically connected. A focused ion beam technique now enables precise sculpting of complex 3D nanostructures from single-crystal materials, including the Helical devices that showcase how far this approach can be pushed.

In practical terms, the beam acts like a programmable knife that can cut trenches, arcs, and overhangs with nanometer precision, all while the sample remains anchored to its substrate. The researchers describe this as a Nanoscale Sculpting Tool, capable of twisting a crystal so that its geometry changes how electricity flows and how the magnetization of the structure responds. Because the method works on single-crystalline Co3Sn2S2, it opens the door to applying the same strategy to other correlated and topological materials where symmetry is everything.

Geometry as a new source of symmetry breaking

What makes these 3D nanostructures more than just fabrication stunts is the way they treat geometry as a first-class design parameter. In conventional device engineering, symmetry breaking usually comes from intrinsic properties such as magnetic order or spin–orbit coupling. Here, the researchers argue that the shape of the device itself can be placed on equal footing with those intrinsic factors, because a helix or twisted bridge can break symmetries that a flat bar cannot. First author Max Birch captures this by describing geometry as a source of symmetry breaking that stands alongside the material’s built-in properties.

That perspective is already visible in the behavior of the 3D helices, where the chiral device geometry modifies the emergent electronic and magnetic responses. By twisting the crystal, the team effectively rewrites which symmetries are allowed and which are forbidden, which in turn changes how electrons move and how spins align. In my view, that is the conceptual leap: geometry is no longer just a constraint imposed by fabrication, it is a deliberate lever for engineering quantum behavior.

Why 3D nanoscale devices matter for future technologies

The implications of this work extend well beyond a single magnetic Weyl semimetal. Three-dimensional nanoscale devices can pack more functionality into a given footprint, route currents along complex paths, and couple mechanical, electrical, and magnetic effects in ways that flat structures cannot. A Focused ion beam-based nanofabrication approach that produces 3D helical devices from single-crystalline Co3Sn2S2 hints at future components where chiral geometry is used to control signal flow or filter spin-polarized currents.

At the same time, the broader field of nanoscale devices is increasingly looking to 3D architectures to overcome the limits of planar scaling. By combining the Nanosculpting approach with insights from Nature Nanotechnology reports on how twisting a crystal changes current flow, engineers can begin to imagine memory elements, sensors, and logic components that rely on controlled torsion or curvature. In that sense, the focused ion beam is not just a fabrication upgrade, it is a gateway to devices where the wild 3D shapes are the function, not just the form.

More from Morning Overview