Permanent magnets sit at the heart of the green economy, from wind turbines and electric vehicles to smartphones and industrial robots. For decades, the strongest versions have depended on rare-earth metals such as neodymium and dysprosium, materials that are costly, politically sensitive, and environmentally fraught to mine. A new wave of ultra-strong magnets built from common elements like iron, nitrogen, manganese, aluminum, and even everyday iron oxide is starting to challenge that dependence, promising powerful performance without rare-earth baggage.

Instead of tweaking the old recipes, researchers and startups are rethinking magnet chemistry and manufacturing from the ground up. They are drawing on advances in materials science, artificial intelligence, and cleaner processing to design magnets that match or rival rare-earth performance while cutting cost and supply risk. If these efforts scale, the invisible hardware that powers the energy transition could become far more sustainable.

The rare-earth problem the new magnets are trying to solve

Modern clean technologies lean heavily on rare-earth magnets, particularly neodymium and dysprosium, which underpin high-torque motors and compact generators. The global supply of these elements is concentrated in a handful of countries, and their extraction is environmentally damaging, expensive, and tightly controlled, a combination that creates strategic vulnerabilities for manufacturers of electric vehicles, wind turbines, and other Clean Energy Transition hardware. As demand for neodymium and dysprosium in modern technologies accelerates, the scramble for supply is colliding with local opposition to new mines and processing plants. That tension is pushing governments and companies to look for ways to either use less rare earth or avoid it entirely.

Advocates of alternative magnets argue that the status quo is not just a climate risk but a geopolitical one. A video on AI-designed magnets notes that rare-earth extraction is environmentally damaging, expensive, and heavily concentrated in a small number of countries, a pattern that leaves clean-energy technologies exposed to price shocks and export controls, However risky for long term planning. Analysts tracking projects such as Chatree REE in Thailand, which markets itself as unlocking that country’s rare-earth power for 2026, frame neodymium and dysprosium as critical inputs for the transition to a greener economy, but also as a bottleneck that could slow deployment if alternatives do not mature in time, according to Neodymium and Dysprosium demand projections.

Iron, nitrogen and everyday oxides: building magnets from common elements

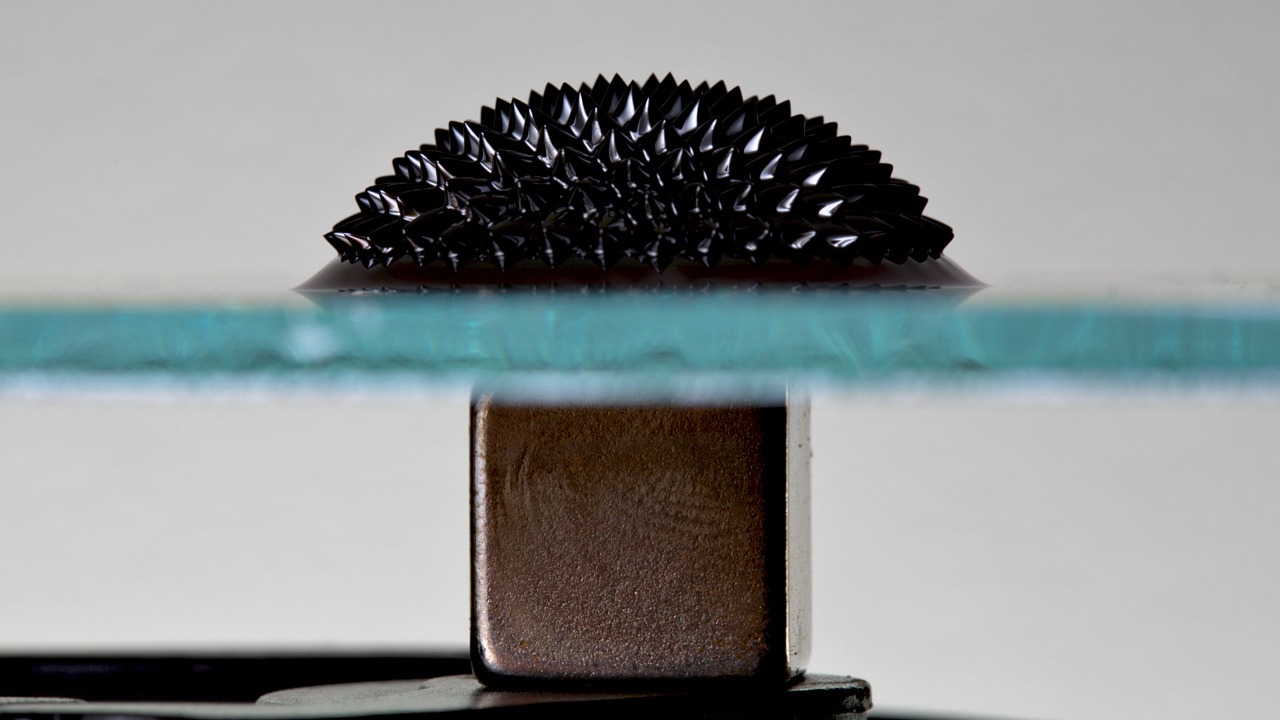

The most striking shift is the move toward magnets built from abundant elements that can be sourced almost anywhere. Iron nitride has emerged as a leading candidate, combining iron and nitrogen into a structure that can deliver high magnetic performance without rare-earth content. Analysts describing Promising Materials in Green Magnet Design highlight iron nitride as a Powerful Alternative, noting that iron is cheap and widely available while nitrogen is common as muck and can be distilled straight from the air with relatively simple equipment, as explained in coverage of how to build strong magnets without rare-earth metals that emphasizes But simple air separation.

Researchers are also revisiting iron oxides, the rust-colored compounds that show up in everything from pigments to magnetic recording media. A study described under the banner Common Elements argues that everyday iron oxide could replace rare-earth metals for future gadgets, suggesting that carefully engineered oxide structures might deliver the coercivity and stability needed for compact devices, according to Everyday Iron Oxide and Earth Metals for. In parallel, materials physicists at Sheffield University, including Elizabeth Davis-Fowell, have shown that alloys such as MnAlGa, which replace rare earths with manganese, aluminum, and gallium, could be a good alternative for some applications, as detailed in work on Materials from Sheffield University that Davis-Fowell and colleagues argue can power the green economy.

From lab to factory: Niron Magnetics and industrial motor breakthroughs

Turning these chemistries into real products is the next test, and some companies are already moving beyond prototypes. In Minnesota, Niron Magnetics is developing sustainable, cost-efficient permanent magnets that avoid rare-earth metals entirely, targeting uses in electric vehicle engines and defense systems, according to reporting that describes the firm as a Minnesota-based company in WASHINGTON working on rare earth free permanent magnets for applications such as motors used in electric vehicle engines, as detailed By Allyson Park in coverage of Minnesota innovation. The company’s technology is Based on research from Professor Jian-Ping Wang, who co-founded Niron Magnetics and developed a process for making permanent magnets from iron and nitrogen, a combination that promises high performance without rare-earth inputs, as explained in a profile of Professor Jian and Niron Magnetics.

Industrial motors are another proving ground for rare-earth-free designs. One solution to the challenge of replacing neodymium magnets in heavy-duty equipment was discovered by a team of researchers and industry partners led by scientists at the U.S. Departm of Energy’s Ames Laboratory, who developed a rare earth free magnet for use in industrial motors that resists avalanche-loss of magnetism at high temperatures, according to a report on how One team at Ameslab.gov tackled the problem. That work, which focuses on alloys that maintain magnetism under thermal stress, is already being positioned as a drop-in option for factories that want to cut rare-earth use without redesigning entire motor platforms, and it complements broader discussions of scientists develop solutions that keep industrial equipment running efficiently.

AI-designed “cosmic” magnets and the Cambridge connection

Artificial intelligence is accelerating magnet discovery by sifting through vast combinations of elements and crystal structures far faster than human trial and error. Materials Nexus, an MD One portfolio company that uses AI to design novel materials for net-zero technologies, announced that its algorithms identified MagNex, a new rare earth free permanent magnet that can be synthesized and tested in a fraction of the time traditional research would require, according to a statement from Materials Nexus and One of its investors. A separate report on a UK start-up notes that the company, called Materials Nexus, designed, synthesised and tested the MagNex material in roughly three months, or around one hundred times faster than conventional development cycles, underscoring how AI can compress the path from simulation to hardware, as detailed in coverage of Materials Nexus and its ability to turn candidate materials into usable products.

At the University of Cambridge, researchers are taking a complementary approach by rethinking how magnets are manufactured rather than just which elements they use. Researchers from the University of Cambridge have discovered a new way to create a possible replacement for rare earth magnets, filing a patent application for the technology and describing how their process can tune microstructures to deliver strong magnetic performance, according to a report on Researchers at the University of Cambridge. A related project describes a New approach to cosmic magnet manufacturing that could reduce reliance on rare earths in low-carbon technologies, with the University of Camb team drawing inspiration from naturally occurring magnetic structures and exploring scalable processing routes, as outlined in a summary of the New method at the University of Camb. Together, these efforts suggest that AI-guided design and novel manufacturing can converge on magnets that are both strong and straightforward to produce at scale.

Cleaner rare-earth supply and the road ahead

Even as alternative magnets advance, rare earths will remain essential in some high performance applications, which is why cleaner extraction and refining are part of the same story. Researchers at Lawrence Livermore National Laboratory and their collaborators have developed a new process for magnet materials that delivers a rare-earth element at high purity and high efficiency, skipping some of the most energy intensive steps in conventional refining, according to a description that notes how Download Image materials from Lawrence Livermore National partners highlight the gains. A related analysis explains that compared to traditional refining approaches, the process skips two major, energy intensive steps and does not produce harmful gases, which could cut the carbon footprint of magnet materials manufacturing, according to comments summarized under the heading Compared with legacy methods.

More from Morning Overview