Elon Musk recently unveiled SpaceX’s Raptor 3 engine, a groundbreaking development in the company’s Starship program. The Raptor 3, SpaceX’s most powerful methane-fueled engine to date, delivers a thrust of 280 metric tons while operating at a chamber pressure of 350 bar. This iteration features a simplified design without an external heat shield, integrating regenerative cooling directly into the chamber walls, thereby reducing complexity and mass. The engine’s evolution includes significant improvements in reliability, with the engine now capable of full-duration burns exceeding 100 seconds in testing at SpaceX’s McGregor facility in Texas.[1][2][3]

The Design Innovations of Raptor 3

The Raptor 3 engine’s design is a testament to SpaceX’s commitment to innovation and efficiency. The elimination of the external heat shield, which previously added unnecessary weight and complexity, allows the engine to rely solely on internal regenerative cooling using methane and oxygen for thermal management.[2] Furthermore, the integration of the turbopump and injector into a more compact assembly has reduced the part count by 40% compared to Raptor 2, enabling higher chamber pressures without structural failures.[3]

Another significant innovation is the use of 3D-printed copper alloy components for the combustion chamber. These components can withstand temperatures over 3,000 Kelvin, while minimizing manufacturing time to under 30 days per unit.[1] These design innovations not only enhance the engine’s performance but also streamline its production process.

Evolution from Raptor 1 to Raptor 3

The evolution of the Raptor engine series is a story of continuous improvement and technological advancement. The journey began with Raptor 1’s initial thrust of 185 metric tons in 2019 tests, which focused on proving full-flow staged combustion cycle feasibility using liquid methane and oxygen.[3] Then came Raptor 2’s upgrades in 2022, which increased thrust to 230 metric tons and improved specific impulse to 330 seconds through optimized nozzle geometry and reduced cavitation in turbopumps.[2]

As of September 2025, Raptor 3 has made a significant leap to 280 metric tons of thrust. This iteration emphasizes reliability enhancements like dual-redundant igniters for restart capability during orbital maneuvers.[3] The evolution of the Raptor series demonstrates SpaceX’s commitment to pushing the boundaries of space technology.

Thrust and Performance Metrics

Raptor 3’s performance metrics are impressive. The engine achieves a chamber pressure of 350 bar, a 20% increase over Raptor 2. This increase directly correlates to higher exhaust velocity and efficiency, crucial for deep-space missions.[1] The specific impulse rating of 350 seconds at sea level for Raptor 3 enables Starship to achieve payload capacities exceeding 150 tons to low Earth orbit in reusable configurations.[4]

Moreover, the thrust-to-weight ratio improvements to over 200:1 allow for lighter engine gimbals and more responsive vector control during ascent phases.[3] These performance metrics underscore the Raptor 3’s capabilities and its potential to revolutionize space travel.

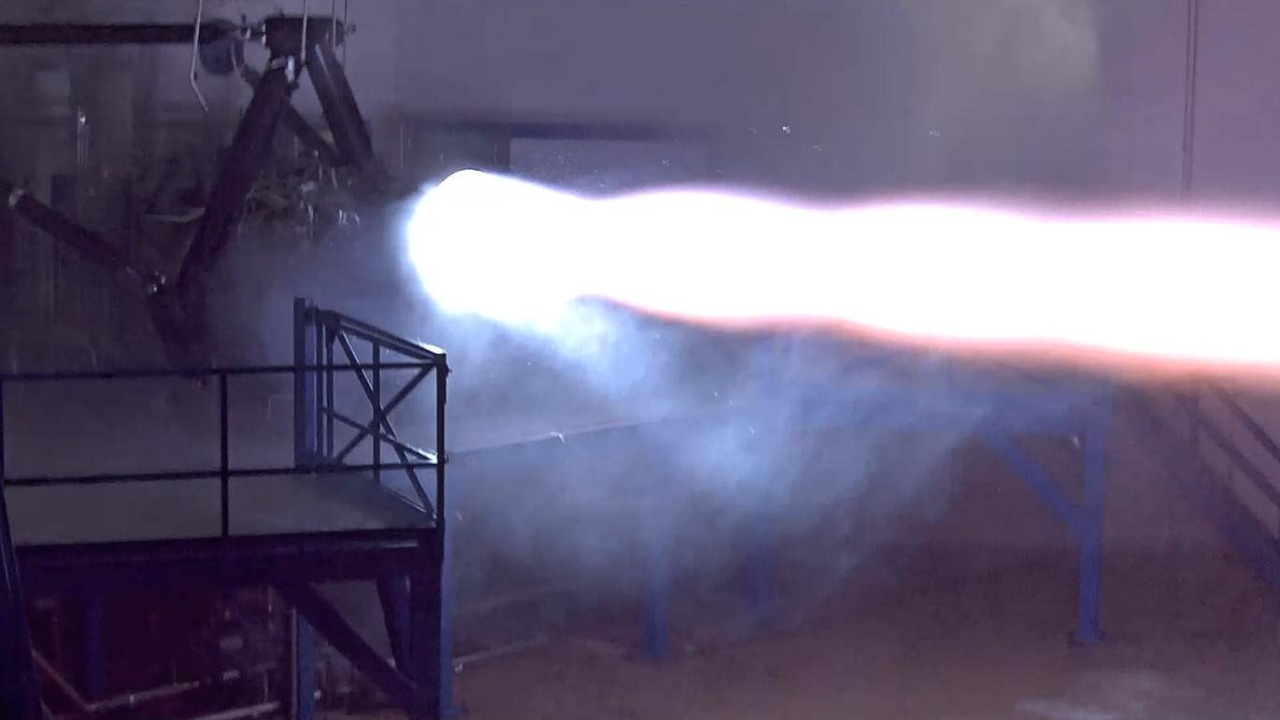

Testing and Reliability Advancements

Reliability is a key factor in the success of any engine, and the Raptor 3 is no exception. Extensive hot-fire testing at McGregor, Texas, saw Raptor 3 complete over 50 consecutive firings without anomalies, demonstrating a throttle range from 40% to 100% power.[2] Additionally, SpaceX has resolved integration challenges for Starship’s 33-engine booster cluster, including synchronized startup sequences to prevent pressure imbalances during ignition.[4]

The upcoming Starship test flight in late 2025 will validate Raptor 3’s performance in vacuum conditions. This could potentially enable rapid reusability with turnaround times under 24 hours, further enhancing the engine’s efficiency and cost-effectiveness.[4]

Materials and Manufacturing Breakthroughs

SpaceX’s material and manufacturing innovations have played a significant role in the development of the Raptor 3. The company has adopted advanced Inconel alloys for the nozzle extension, which are resistant to erosion at 3,500 m/s exhaust velocities, extending engine life to over 1,000 seconds of cumulative burn time.[3] Furthermore, SpaceX’s in-house 3D printing facility in Hawthorne, California, produces Raptor 3 injectors with 1,500 elements in a single piece, cutting assembly costs by 50%.[2]

Another breakthrough is the shift to methane-compatible seals using silicone-based composites. This eliminates leaks observed in early Raptor prototypes and ensures cryogenic performance down to -183°C.[1] These advancements in materials and manufacturing techniques not only enhance the engine’s performance but also its longevity and reliability.

Implications for Starship Missions

The Raptor 3’s higher thrust enables Starship’s Super Heavy booster to generate approximately 9,240 metric tons of total liftoff force, surpassing NASA’s SLS by over 20% for lunar and Mars trajectories.[4] Furthermore, Raptor 3 is designed for 20+ flights per engine through automated health monitoring via embedded sensors tracking vibration and temperature in real-time.[3]

Elon Musk has stated that Raptor 3 plays a crucial role in achieving Mars colonization goals, including propellant production compatibility for in-situ resource utilization on the Red Planet.[1] These implications underscore the engine’s potential in advancing space exploration and colonization.

Future Iterations and Industry Impact

The development of Raptor 4 is projected to aim for 300 metric tons thrust by 2027 through AI-optimized combustion modeling, building on Raptor 3’s data from integrated flight tests.[3] Compared to rivals like Blue Origin’s BE-4, Raptor 3’s full-flow cycle offers 10% better efficiency for heavy-lift applications, providing SpaceX with a competitive edge.[2]

Furthermore, the broader aerospace industry could benefit from Raptor-derived tech for satellite launches, as hinted in SpaceX’s 2025 partnerships announcements.[4] The Raptor 3 engine, with its innovative design and impressive performance metrics, is poised to have a significant impact on the future of space exploration and the aerospace industry at large.