The world’s largest piston engine stands as a testament to modern engineering, demonstrating extraordinary power and efficiency, particularly in maritime settings. This engine’s capabilities not only highlight significant advancements in engineering but also underscore its indispensable role in global commerce and technological progress.

The Mechanics of the World’s Largest Piston Engine

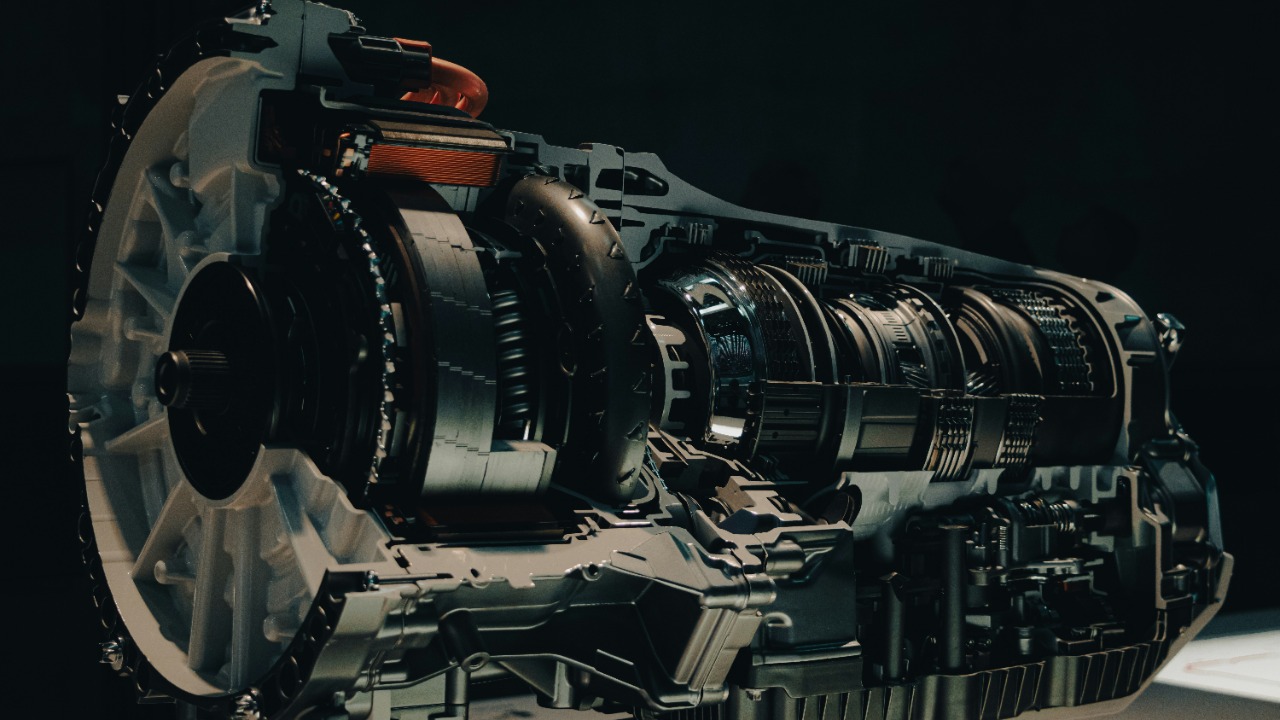

The Wärtsilä-Sulzer RTA96-C is a marvel in the world of piston engines with an impressive design and set of specifications. This two-stroke turbocharged diesel engine is primarily used to power massive container ships. It boasts a height of 13.5 meters and a length of 26.59 meters, making it a giant in its class. With a power output that can reach up to 107,390 horsepower, it dwarfs other large engines in terms of performance. The engine’s construction includes 14 cylinders, each with a bore of 960 mm and a stroke of 2,500 mm, contributing to its colossal size and output.

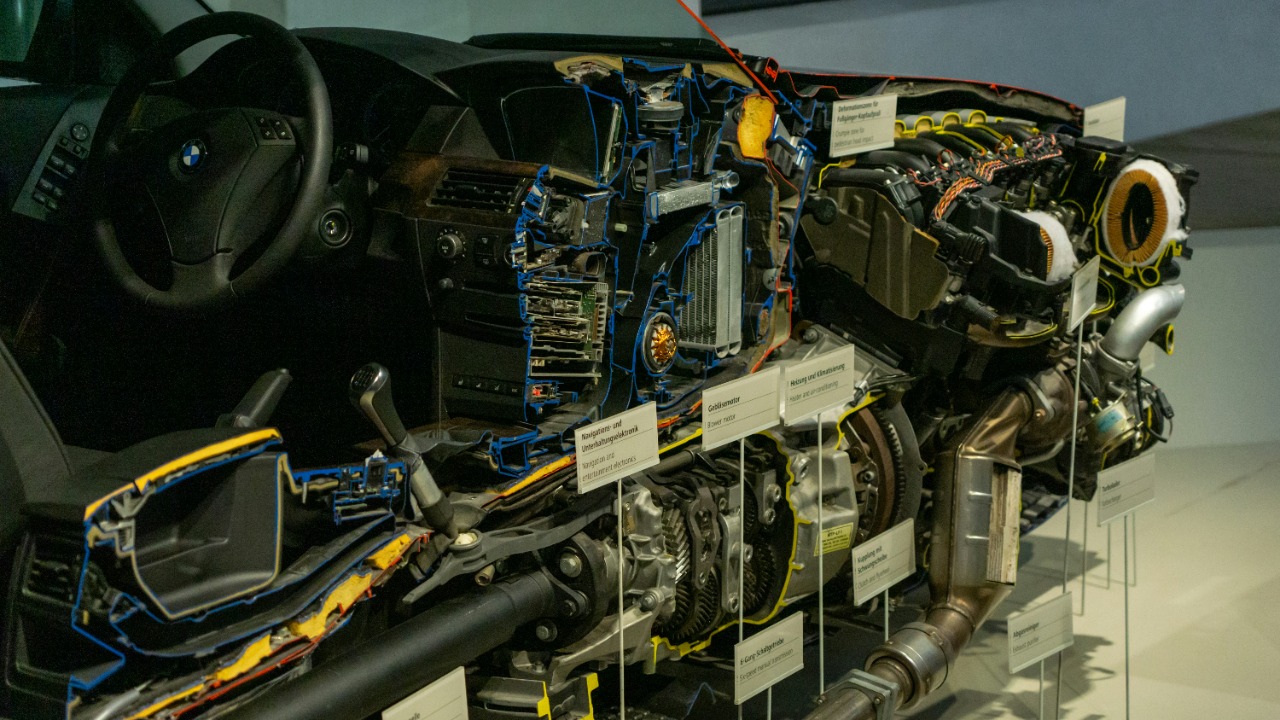

Developing an engine of this magnitude comes with several engineering challenges and innovations. The technological advancements required to build and maintain such an engine are significant. For instance, the materials used in its construction must withstand extreme conditions, including high thermal and mechanical stresses. Manufacturing this engine demands precision and sophisticated machinery, while maintenance requires specialized skills and equipment. The scale of the engine also necessitates logistical planning for transportation and assembly within the ship’s hull.

Power and Performance Metrics

The Wärtsilä-Sulzer RTA96-C’s power is quantified by its staggering horsepower and torque capabilities. This engine produces up to 107,390 horsepower and generates 5,608,312 lb-ft of torque, offering unmatched performance in its class. These metrics are achieved through its massive cylinders and turbocharging technology, which enhances air intake and increases combustion efficiency. Compared to smaller engines, the RTA96-C is a powerhouse, although its efficiency in terms of power-to-weight ratio may not be as high as smaller, more agile engines.

Fuel efficiency and environmental considerations are critical factors in the engine’s design. The RTA96-C consumes approximately 1,660 gallons of heavy fuel oil per hour, which is efficient given its size and power output. However, such consumption also raises concerns about emissions. The engine’s design includes measures to reduce nitrogen oxide emissions, complying with international maritime environmental regulations. Innovations in fuel technology and engine design continue to evolve, aiming to reduce the environmental impact of these massive engines further.

Applications and Uses

In the maritime industry, the Wärtsilä-Sulzer RTA96-C plays an essential role. This engine powers some of the world’s largest container ships and tankers, facilitating global shipping and trade. These vessels are vital to international commerce, transporting goods across continents and supporting the logistics of countless industries. The engine’s ability to provide reliable and powerful propulsion is crucial for maintaining the efficiency and speed of these massive ships on global trade routes.

While primarily used in maritime applications, there is potential for the RTA96-C to find uses in other industries. For example, its power and efficiency could be harnessed for energy generation in large-scale industrial settings. However, adapting the engine for non-maritime uses presents challenges, including the need for infrastructure to support its size and fuel requirements. The logistical and environmental considerations must also be addressed before such applications can become viable.

Economic and Global Impact

The Wärtsilä-Sulzer RTA96-C significantly contributes to global trade and the economy. By powering the vessels that transport goods across the world, it supports the logistics backbone of international commerce. The engine’s efficiency and capacity translate into economic benefits, reducing shipping costs and enabling the movement of large quantities of goods efficiently. This, in turn, helps to stabilize and grow economies by ensuring a steady supply of products and materials.

Looking towards the future, ongoing research and development efforts focus on creating even larger and more powerful engines. Innovations in materials science and engineering techniques promise to push the boundaries of what is possible, potentially leading to engines that are not only more powerful but also more efficient and environmentally friendly. These advancements could revolutionize global shipping and other industries reliant on large-scale propulsion systems.

Innovations and the Future of Large Engine Technology

Emerging trends in engine technology continue to influence the development of large engines like the RTA96-C. Advances in materials, such as lightweight alloys and heat-resistant composites, play a crucial role in enhancing engine performance and durability. Additionally, the integration of digital technologies, such as advanced sensors and real-time data analytics, allows for performance optimization and predictive maintenance, ensuring engines operate at peak efficiency.

Sustainability is also a growing focus in the realm of large engine technology. The shift towards greener alternatives includes exploring potential sustainable fuels and technologies, such as biofuels and synthetic alternatives. Balancing the need for power with environmental responsibilities is a complex challenge, but one that is driving innovation and development in the industry. The future may see a blend of traditional engineering prowess with cutting-edge sustainable practices, paving the way for a new era of large piston engines.