3D printing is revolutionizing rocket science by enabling on-demand space launches and advancing technological capabilities. Companies like Agnikul, which operates in India, are at the forefront of this innovation, utilizing 3D printed rocket engines to enhance efficiency and reduce costs. Recent developments highlight the transformative impact of 3D printing on the aerospace industry, showcasing its potential to reinvent traditional rocket manufacturing processes.

The Role of 3D Printing in Rocket Manufacturing

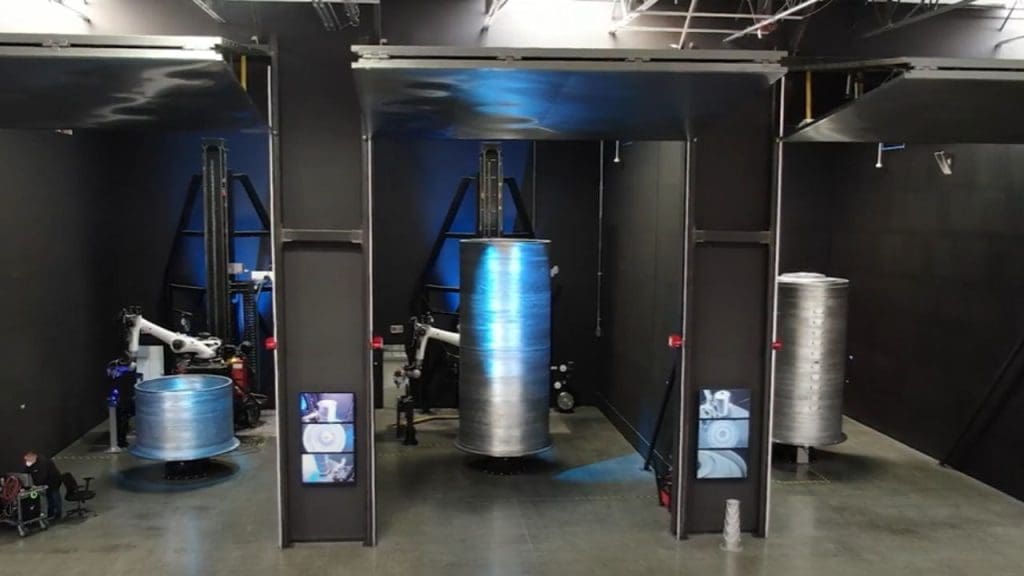

3D printing technology is pivotal in creating complex rocket components that are otherwise challenging to manufacture using traditional methods. This capability allows for intricate designs that enhance the performance and reliability of rockets. According to MSN, the ability to produce these components with precision and speed is a game-changer for the aerospace industry, enabling manufacturers to push the boundaries of what is possible in rocket design.

The reduction of manufacturing time and costs associated with 3D printed rocket parts is another significant advantage. As reported by IEEE Spectrum, companies like Agnikul are leveraging 3D printing to streamline production processes, significantly cutting down the time it takes to produce rocket engines. This efficiency not only reduces costs but also allows for rapid prototyping and testing, accelerating the development cycle of new rocket technologies.

Moreover, the integration of 3D printing technology into rocket manufacturing processes has improved performance metrics across the board. By enabling the production of lighter and more efficient components, companies can achieve better fuel efficiency and payload capacity. This integration is a testament to the versatility and potential of 3D printing in revolutionizing the aerospace sector.

In addition to enhancing design capabilities, 3D printing also facilitates the customization of rocket components to meet specific mission requirements. This adaptability is crucial for tailoring rockets to different payloads and destinations, allowing for optimized performance in various space environments. As noted by MSN, the precision of 3D printing ensures that each component can be fine-tuned to achieve the desired balance between weight and strength, which is essential for successful space missions.

Furthermore, the use of 3D printing in rocket manufacturing supports the development of more sustainable production practices. By reducing the need for multiple parts and minimizing waste, 3D printing contributes to a more environmentally friendly manufacturing process. This approach not only aligns with global sustainability goals but also enhances the overall efficiency of the aerospace industry, as highlighted by IEEE Spectrum.

Advantages of 3D Printing for Space Launches

One of the most significant advantages of 3D printing in the context of space launches is the ability to produce rocket components on demand. This capability facilitates quicker and more flexible space launches, as companies can manufacture parts as needed rather than relying on long supply chains. According to IEEE Spectrum, this flexibility is crucial for meeting the dynamic demands of modern space exploration and commercial satellite deployment.

Cost efficiency improvements are another critical benefit of 3D printing in rocket manufacturing. By reducing waste and minimizing material usage, companies can significantly lower the cost of building rockets. As highlighted by MSN, this reduction in material costs, combined with the decreased need for extensive labor and machining, makes 3D printing an economically viable option for the aerospace industry.

There are already examples of successful 3D printed rocket launches that demonstrate the technology’s potential. These launches not only validate the reliability and performance of 3D printed components but also pave the way for future space missions that could benefit from the same technological advancements. The implications for future space exploration are profound, as 3D printing could enable more frequent and cost-effective missions.

3D printing also plays a crucial role in enhancing the reliability of space launches. By producing components with fewer joints and welds, the risk of mechanical failure is significantly reduced. This improvement in reliability is particularly important for missions involving human spaceflight, where safety is paramount. As reported by MSN, the ability to produce seamless components contributes to the overall robustness of the rocket, ensuring that it can withstand the harsh conditions of space travel.

Additionally, the flexibility offered by 3D printing allows for the rapid iteration of designs, enabling engineers to test and refine components quickly. This capability is essential for adapting to the fast-paced demands of the aerospace industry, where technological advancements are continually reshaping mission parameters. As noted by IEEE Spectrum, this agility in design and production is a key factor in maintaining competitiveness in the global space market.

Pioneers in 3D Printed Rocket Technology

Agnikul, an Indian company, is leading the charge in 3D printed rocket engines with its innovative approaches. As detailed by IEEE Spectrum, Agnikul’s use of 3D printing technology allows them to produce entire rocket engines in a single piece, reducing the need for assembly and increasing the reliability of their products. This approach not only enhances efficiency but also positions Agnikul as a pioneer in the field of aerospace innovation.

Other key players in the industry are also adopting 3D printing technology to push the boundaries of rocket science. Companies around the globe are exploring how 3D printing can be integrated into their manufacturing processes to improve performance and reduce costs. As noted by MSN, these efforts are driving a new era of innovation in the aerospace sector, with 3D printing at its core.

Collaborative efforts within the industry are further advancing 3D printing technologies and their applications in rocketry. By sharing knowledge and resources, companies can accelerate the development of new technologies and bring them to market more quickly. This collaboration is essential for maintaining the momentum of innovation and ensuring that 3D printing continues to transform the aerospace industry.

Future Prospects of 3D Printing in Aerospace

The future prospects of 3D printing in aerospace are promising, with potential developments and innovations on the horizon that could further transform the industry. As reported by MSN, advancements in materials science and printing techniques could lead to even more efficient and capable rocket components, opening up new possibilities for space exploration and commercial applications.

The long-term impact of 3D printing on cost structures and the accessibility of space exploration is significant. By reducing the costs associated with manufacturing and launching rockets, 3D printing could democratize access to space, allowing more countries and companies to participate in space exploration. According to IEEE Spectrum, this increased accessibility could lead to a new era of innovation and discovery in space.

Finally, the potential for 3D printing to enable sustainable practices in rocket manufacturing and space travel is an exciting prospect. By minimizing waste and optimizing material usage, 3D printing can contribute to more environmentally friendly manufacturing processes. As the aerospace industry continues to evolve, the role of 3D printing in promoting sustainability will likely become increasingly important, shaping the future of space exploration for generations to come.