A German firm has introduced groundbreaking high-insulation coatings designed to protect electric vehicle (EV) batteries from extreme temperatures, specifically up to 2,192°F. This innovation addresses critical thermal management challenges, enhancing the safety and durability of battery systems in high-heat scenarios, such as fires or extreme environments. The development promises to significantly improve the resilience of EV batteries, a crucial factor in the advancement of electric mobility.

The Innovation Unveiled

The debut of these high-insulation coatings marks a significant milestone in the field of electric vehicle technology. Developed by a German firm, these coatings are specifically engineered to withstand extreme heat, providing a robust solution to the thermal challenges faced by EV batteries. This announcement, reported on October 7, 2025, introduces a new era of protective technology that could redefine safety standards in the automotive industry. The coatings are designed to offer superior protection, ensuring that EV batteries remain stable even under the most demanding conditions (Interesting Engineering).

This innovation is particularly timely as the demand for electric vehicles continues to rise, necessitating advancements in battery safety and efficiency. By addressing the issue of thermal runaway—a major safety concern in battery technology—these coatings could play a pivotal role in the widespread adoption of electric vehicles. The German firm’s introduction of this technology positions it at the forefront of materials innovation, offering a solution that could be critical in preventing battery fires and enhancing overall vehicle safety.

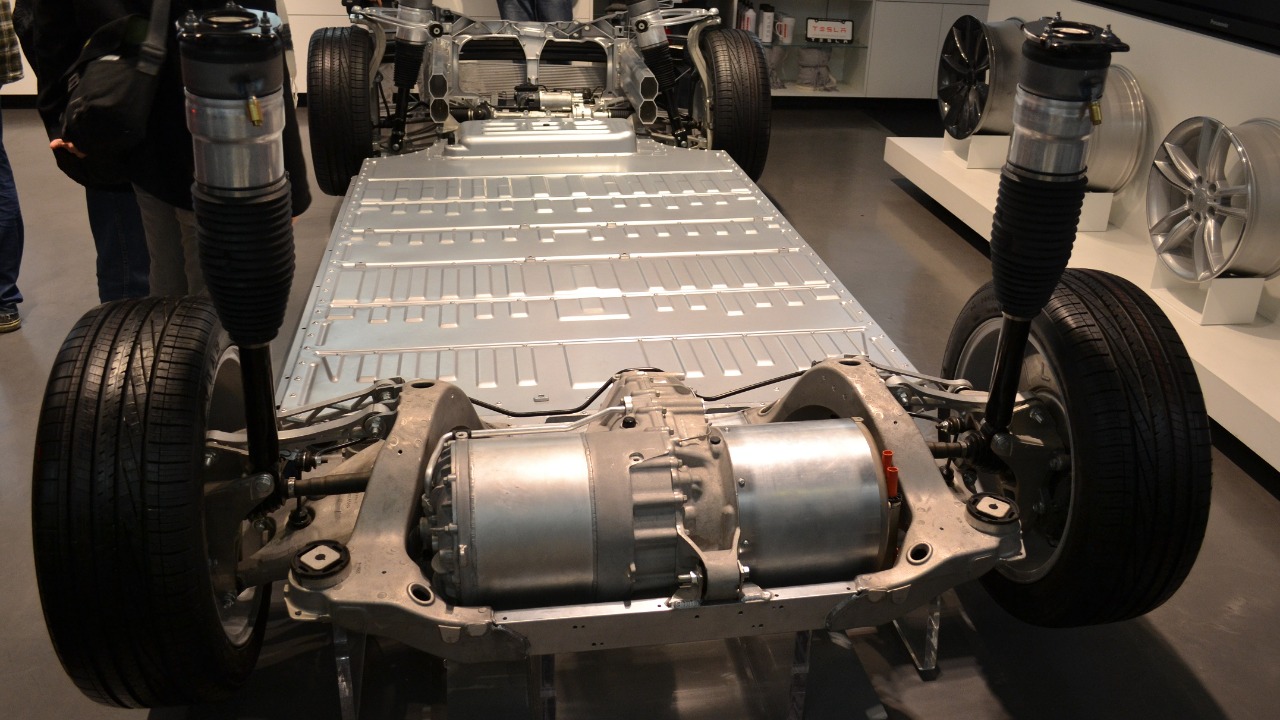

In addition to enhancing safety, these coatings are expected to influence the design and engineering of future electric vehicles. By allowing for more compact and efficient battery designs, manufacturers can optimize space and weight, potentially leading to vehicles with longer ranges and better performance. This technological leap could also reduce the overall cost of EV production by minimizing the need for additional cooling systems, making electric vehicles more accessible to a broader market.

Technical Specifications

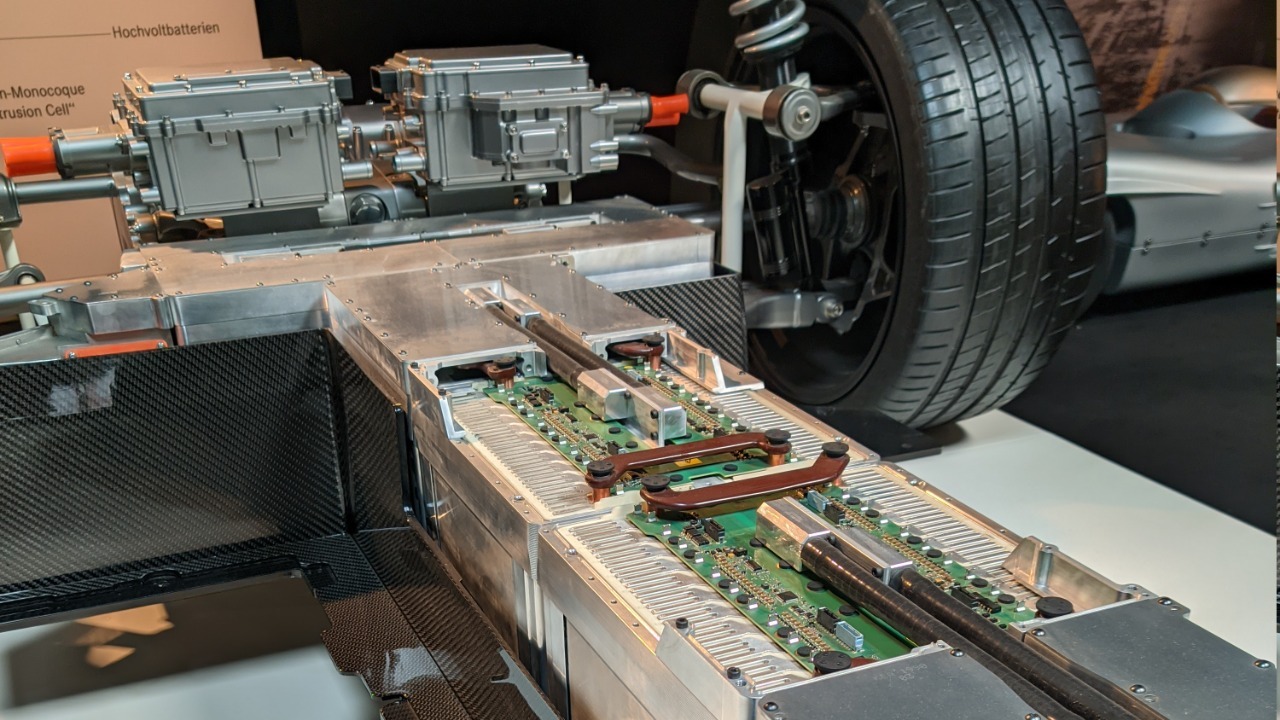

The high-insulation coatings provide heat protection rated at an impressive 2,192°F, a specification that ensures effective insulation against thermal runaway in EV batteries. This level of protection is crucial for maintaining the integrity of battery systems, especially in scenarios where temperatures can soar unexpectedly. The coatings’ high-insulation properties are meticulously tailored for battery applications, offering a specialized solution that addresses the unique thermal challenges of electric vehicles (Interesting Engineering).

By integrating these coatings into battery systems, manufacturers can significantly enhance the thermal management capabilities of their products. This innovation not only improves safety but also contributes to the longevity and reliability of EV batteries, making them more resilient to the stresses of high-temperature environments. The technical prowess of these coatings underscores their potential to transform the landscape of electric vehicle technology, setting new benchmarks for safety and performance.

The coatings are composed of advanced ceramic materials that provide not only thermal resistance but also mechanical durability. This dual functionality ensures that the coatings can withstand physical stresses and vibrations typical in automotive environments, further enhancing the reliability of the battery systems. The ceramic materials used are lightweight, which is crucial for maintaining the energy efficiency of electric vehicles. This innovation represents a significant advancement in materials science, offering a practical solution to one of the most challenging aspects of EV battery design.

Applications and Benefits

The primary application of these high-insulation coatings is in enhancing the fire resistance and overall safety of EV batteries. By providing a robust barrier against extreme heat, the coatings mitigate the risks associated with high temperatures, which are prevalent in both automotive and energy storage contexts. This innovation is particularly beneficial in preventing the catastrophic consequences of battery fires, a concern that has long plagued the electric vehicle industry (Interesting Engineering).

Beyond safety, the coatings offer significant benefits in terms of battery performance and durability. By ensuring that batteries remain stable under extreme conditions, the coatings contribute to the overall efficiency and reliability of electric vehicles. This advancement could lead to broader acceptance of EVs, as consumers and manufacturers alike seek solutions that enhance safety without compromising performance. The potential to mitigate risks from high temperatures makes these coatings a valuable asset in the pursuit of sustainable and reliable electric mobility.

Moreover, these coatings have potential applications beyond the automotive industry. In energy storage systems, particularly those used in renewable energy setups like solar and wind farms, the coatings can provide essential thermal protection, ensuring the longevity and efficiency of battery storage solutions. This cross-industry applicability highlights the versatility of the coatings and their potential to contribute to broader sustainability goals by improving the safety and efficiency of energy storage technologies.

Industry Context

The development of these high-insulation coatings by a German firm positions it as a leader in the field of advanced materials for sustainable transport. This innovation aligns with the growing demands for robust thermal protection in the EV sector, a critical factor as the industry continues to evolve and expand. By offering a solution that addresses one of the most pressing challenges in battery technology, the firm is setting a new standard for safety and performance in electric vehicles (Interesting Engineering).

As the electric vehicle market continues to grow, the need for advanced thermal management solutions becomes increasingly apparent. The introduction of these coatings represents a significant step forward in meeting this demand, providing manufacturers with the tools they need to enhance the safety and reliability of their products. This development not only highlights the innovative capabilities of the German firm but also underscores the importance of continued research and development in the pursuit of safer, more efficient electric vehicles.

The introduction of these coatings comes at a pivotal time as regulatory bodies worldwide are tightening safety standards for electric vehicles. By proactively addressing these regulatory challenges, the German firm not only gains a competitive edge but also contributes to shaping future industry standards. This proactive approach is likely to encourage other companies to invest in similar innovations, fostering a culture of safety and sustainability in the electric vehicle industry. The coatings’ development is a testament to the firm’s commitment to advancing technology that aligns with global environmental and safety objectives.