Airbus is making strides in sustainable aviation technology, with a recent focus on a 3D-printed heat exchanger designed to cool its future hydrogen-electric jets. This innovative approach to thermal management in aviation marks a significant step forward in the development of zero-emission aircraft.

The Role of Heat Exchangers in Hydrogen-Electric Aircraft

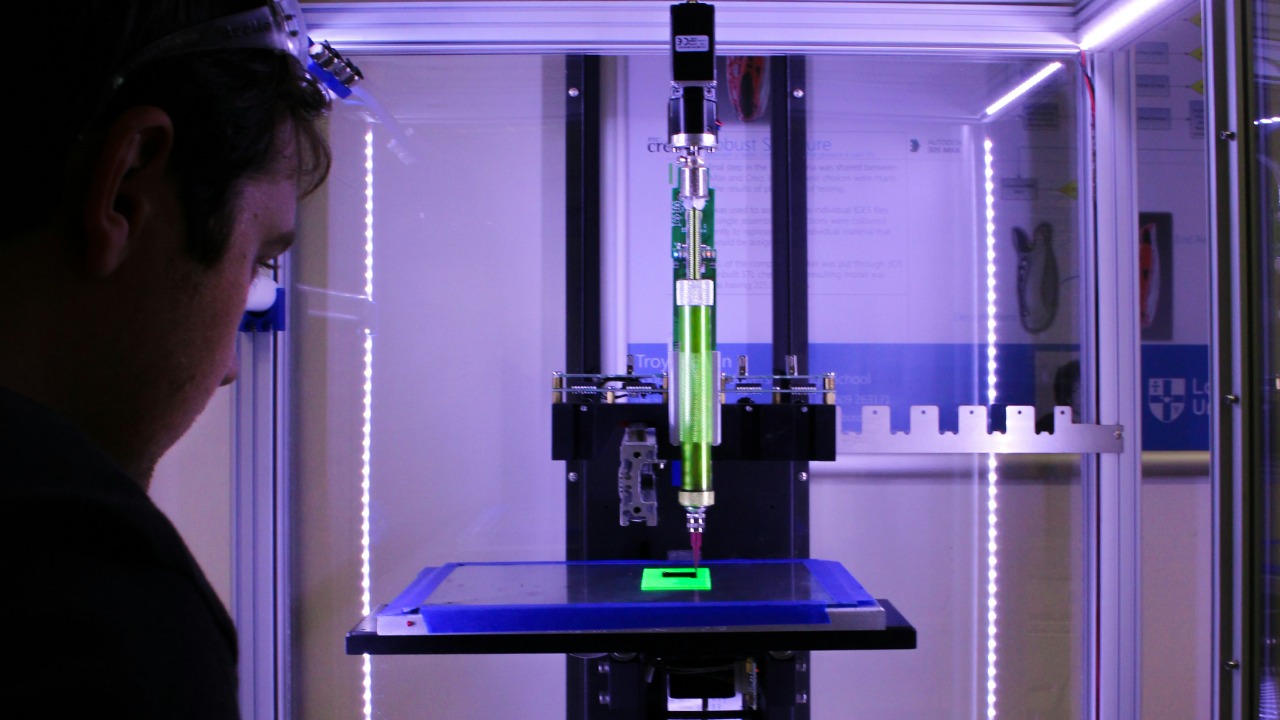

Heat exchangers play a crucial role in managing thermal loads in hydrogen-electric propulsion systems. These devices prevent overheating during flight operations by efficiently transferring heat away from the system. In the context of Airbus’s hydrogen-electric jets, the 3D-printed heat exchanger is designed to provide efficient cooling for the hydrogen-fueled electric propulsion system. This is a key component of Airbus’s broader hydrogen-electric jet designs, which are aimed at achieving zero-emission flight.

The integration of this 3D-printed heat exchanger into Airbus’s hydrogen-electric jets is a testament to the company’s commitment to innovation in sustainable aviation. The heat exchanger is not just a component; it’s a symbol of Airbus’s dedication to pushing the boundaries of what’s possible in the realm of hydrogen-electric aviation. Interesting Engineering reports on this strategic bet by Airbus on the technology for future fleet development.

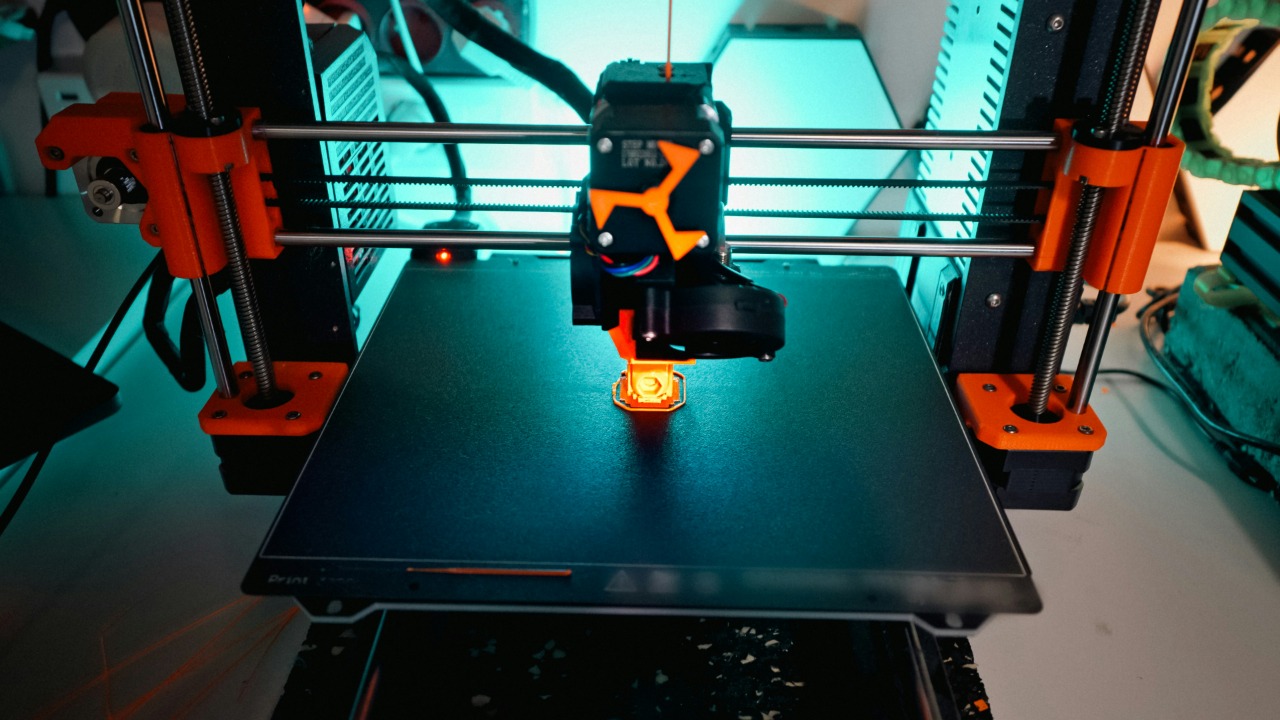

Advancements in 3D Printing for Aerospace Components

3D printing technology has been evolving rapidly, with advancements in materials, printing techniques, and post-processing methods. For instance, the use of high-performance polymers and metal alloys in 3D printing has expanded the range of applications in the aerospace industry. These materials can withstand the harsh conditions of flight, including high temperatures and pressures, making them ideal for components like heat exchangers. Moreover, the ability to print with multiple materials in a single build allows for the creation of parts with varying properties, further enhancing the functionality of the printed components.

Furthermore, the digital nature of 3D printing enables rapid prototyping and iterative design. This means that engineers can quickly test and refine their designs, accelerating the development process. In the case of Airbus’s heat exchanger, this could have allowed for rapid optimization of the design to maximize heat transfer efficiency. This agility in design and manufacturing is a key advantage of 3D printing, and one that Airbus is leveraging in its pursuit of sustainable aviation.

Airbus’s Commitment to Sustainable Aviation

Airbus’s development of hydrogen-electric jets is part of its broader push towards zero-emission aircraft. The company sees hydrogen as a promising energy source for future aviation, and is investing heavily in the development of hydrogen-electric propulsion systems. The 3D-printed heat exchanger is a key component of these systems, and its successful integration into Airbus’s jet designs is a significant milestone in the company’s journey towards sustainable aviation.

Technical Benefits of the 3D-Printed Design

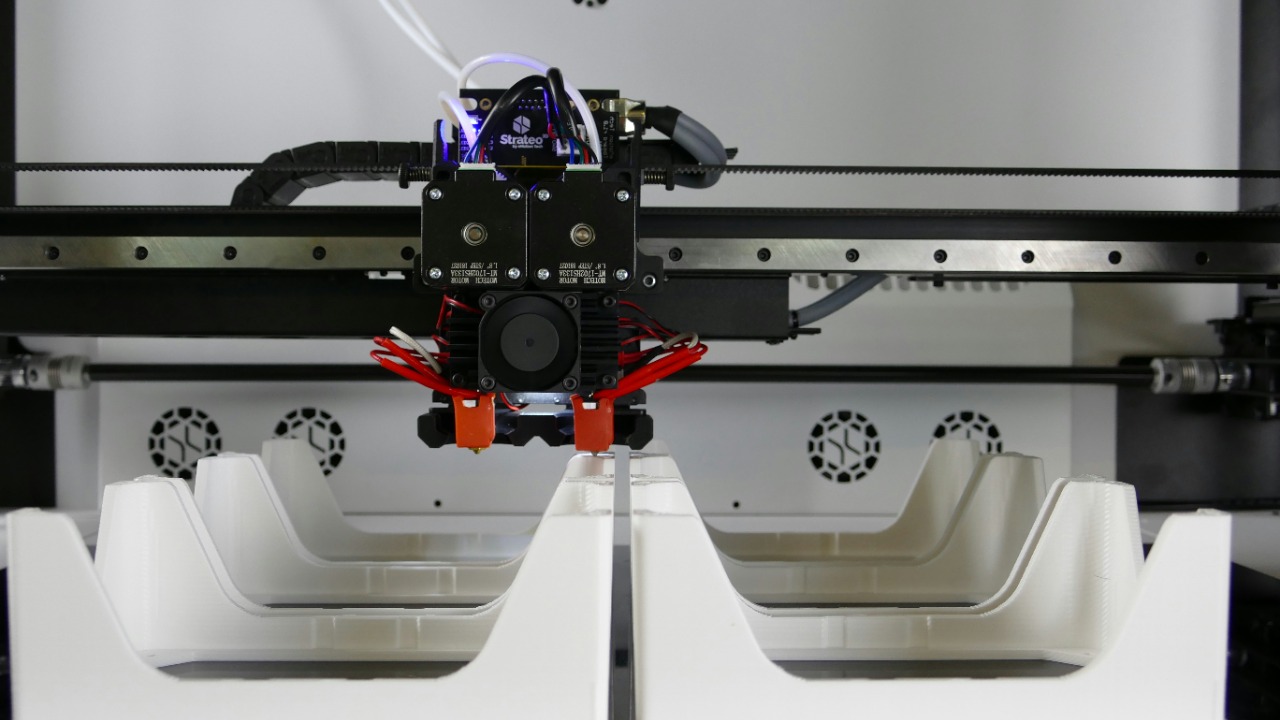

3D printing also offers the advantage of design freedom, enabling the creation of parts with intricate internal structures that would be impossible to manufacture using traditional methods. In the case of the heat exchanger, this could include internal channels for fluid flow, which can be optimized for maximum heat transfer. This level of design complexity can significantly enhance the performance of the heat exchanger, contributing to the overall efficiency of the hydrogen-electric propulsion system.

Moreover, 3D printing can produce parts with fewer assembly components, reducing the risk of failure points. This is particularly important in the aerospace industry, where component failure can have serious consequences. By reducing the number of parts and assembly steps, 3D printing can enhance the reliability and safety of aerospace components like the heat exchanger.

Challenges and Innovations in Cooling Hydrogen Systems

One of the key challenges in cooling hydrogen systems is dealing with the extreme temperatures involved. Hydrogen combustion can reach temperatures of over 2000 degrees Celsius, far higher than traditional jet fuels. This requires heat exchangers that can withstand these extreme conditions while maintaining high levels of performance. Airbus’s 3D-printed heat exchanger is designed to meet these requirements, using advanced materials and design techniques to manage the intense heat generated by hydrogen combustion.

Another challenge is the need for compact, lightweight cooling solutions. In aviation, every gram counts, and bulky or heavy components can significantly impact fuel efficiency and flight range. Airbus’s 3D-printed heat exchanger addresses this challenge with its compact, lightweight design. The use of 3D printing allows for the creation of a highly efficient, compact heat exchanger that minimizes weight while maximizing cooling performance.

Future Implications for Aviation Industry

The success of Airbus’s 3D-printed heat exchanger could have far-reaching implications for the aviation industry. It could pave the way for the wider adoption of 3D printing in the production of aerospace components, leading to more efficient, lightweight, and reliable aircraft. This could significantly reduce the environmental impact of air travel, contributing to the global effort to combat climate change.

Moreover, the development of efficient cooling solutions for hydrogen-electric propulsion systems could accelerate the shift towards zero-emission aviation. As more airlines and aircraft manufacturers recognize the potential of hydrogen as a sustainable fuel source, the demand for efficient, reliable cooling solutions will increase. Airbus’s 3D-printed heat exchanger could serve as a blueprint for future developments in this area, driving innovation and progress in the field of sustainable aviation.