In the captivating realm of aviation maintenance, aging planes remain airborne and even thrive thanks to the utilization of overhauled parts. These revamped components often exceed their initial performance specifications, enabling the aircraft to operate beyond their expected lifespan.

The Current State of the Aging Aviation Fleet

The general aviation fleet is a testament to the longevity of well-maintained aircraft, with many planes operating for several decades. However, as these planes age, they present unique maintenance challenges. Wear and tear, outdated components, and the need for regular inspections are just a few of the complexities involved in keeping an aging fleet airborne.

The aviation industry has adapted to these challenges with innovative solutions. One key strategy is overhauling aircraft parts, a practice that can greatly extend the lifespan of planes. Preserving flight has become a quintessential task in the industry, enabling older planes to meet, and often exceed, their original performance standards.

Understanding Aircraft Overhaul

Aircraft overhaul involves the thorough inspection, disassembly, repair, and reassembly of an aircraft or its components. This process is vital in maintaining the safety and functionality of aging planes. Overhauling is not merely about restoring parts to their original state, but enhancing them to perform better than their initial specifications.

Technology and innovation play a critical role in improving these overhaul procedures. Modern diagnostic tools, precision instruments, and advanced methods contribute to the effectiveness of overhauls. For instance, laser scanning technology aids in the detection of even minor deformities or wear in parts, thus ensuring a more accurate restoration.

The Role of Quality Parts in Aircraft Longevity

Quality overhauled parts are the backbone of aircraft longevity. They not only replace worn-out components but also enhance the overall performance of the aircraft. For example, overhauled engines can deliver more power, better fuel economy, and improved reliability compared to their original counterparts.

There are numerous case studies of planes that have outlived their expected lifespan due to quality overhauled parts. A notable example is the DC-3, a plane first introduced in the 1930s. Numerous DC-3s are still flying today, thanks to the incorporation of overhauled parts. While using overhauled parts in aircraft raises safety considerations, proper maintenance and adherence to industry standards ensure that these parts perform safely and effectively.

Outsourcing Aircraft Servicing, Maintenance, Repair, and Overhaul (MRO)

A growing trend in the aviation industry is the outsourcing of MRO operations. This enables airlines to focus on their core business while leveraging the expertise of specialized MRO providers. Outsourcing MRO operations has played a significant role in the successful overhaul of aging aircraft.

However, outsourcing also comes with potential risks, such as communication issues, quality control challenges, and dependency on the service provider. Despite these risks, the benefits, including cost-effectiveness, access to specialized skills, and increased operational efficiency, often outweigh the downsides.

Future Trends: The Next Generation of Overhauled Aircrafts

As technology advances, so too will the methods and materials used in aircraft overhauls. This could lead to even longer aircraft lifespans and more efficient operations. For instance, the use of advanced composite materials could extend aircraft life by reducing corrosion and wear.

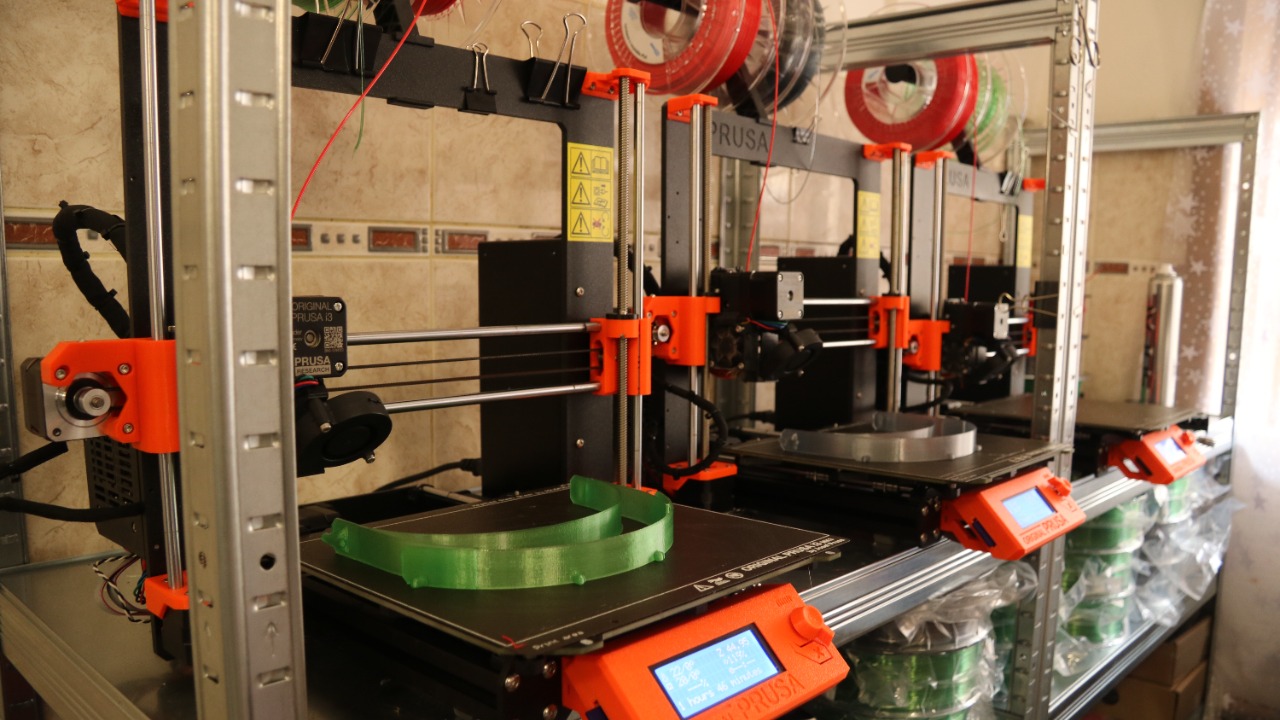

Furthermore, the incorporation of additive manufacturing, or 3D printing, in the overhaul process holds enormous potential. This technology can produce lighter, stronger, and more complex parts, pushing the boundaries of what’s possible in aircraft overhaul. With these advancements, the future of overhauled aircraft looks promising and is set to push the boundaries of aviation even further.

Regulatory Impact on Overhauling Aircraft

Aviation regulatory bodies play a significant role in the overhaul process. These organizations, such as the Federal Aviation Administration (FAA) in the United States, set the standards for overhauling processes and ensure the safety and reliability of overhauled aircraft.

Regulations impact every aspect of aircraft overhaul, from the types of parts that can be used to the procedures for installing and testing these parts. As the overhaul techniques advance, regulations may need to evolve to accommodate these changes while continuing to ensure safety. For further reading, this article provides a detailed commentary on the regulatory impact and its implications on overhauling aircraft.