In the ever-evolving world of robotics, a fascinating trend is emerging: robots building other robots. This shift not only enhances efficiency but also paves the way for innovative developments in various industries. Let’s explore six cutting-edge robotic systems actively contributing to this paradigm shift.

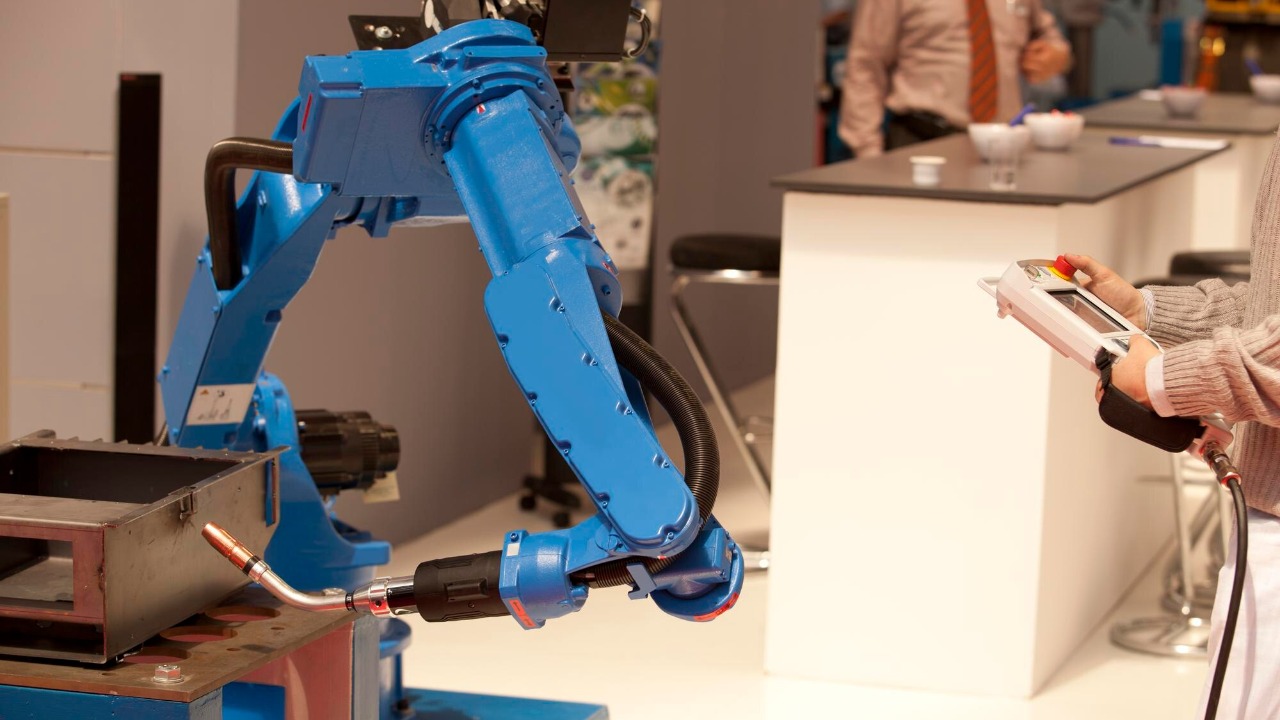

Robotic Arm Assemblers

Robotic arm assemblers are the backbone of modern manufacturing lines, particularly in the assembly of complex machinery including robots. These versatile machines are equipped with precision and dexterity, making them ideal for handling intricate tasks that demand accuracy and consistency. The use of robotic arms in assembling other robots streamlines the process, reducing human error and increasing production speed.

One notable example is the FANUC robotic arms, which are widely used in industries ranging from automotive to electronics. Their ability to perform repetitive tasks tirelessly and with unmatched precision makes them indispensable in the modern factory setting. With the rise of humanoid robots, robotic arm assemblers are becoming increasingly essential in their production, demonstrating their versatility and adaptability.

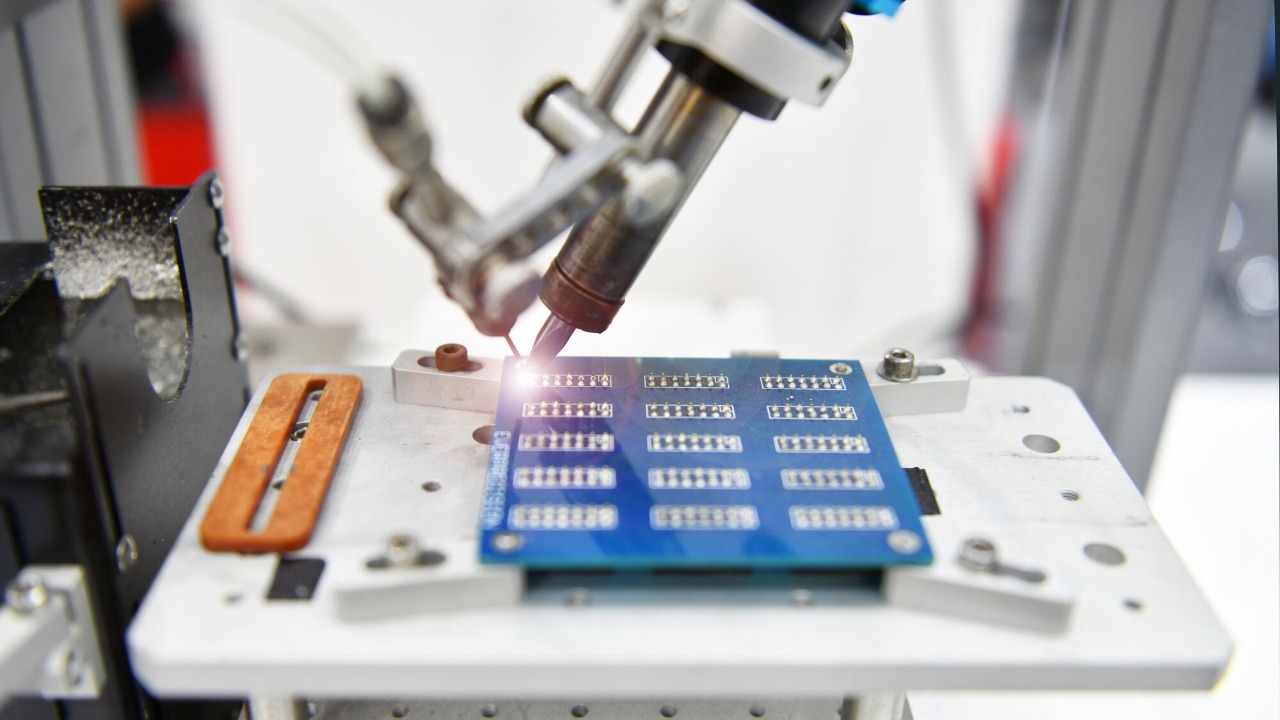

Automated PCB Soldering Machines

Printed Circuit Boards (PCBs) are the heart of any robotic system, and automated PCB soldering machines play a crucial role in their creation. These machines are designed to handle the delicate and precise task of soldering components onto PCBs without human intervention. By automating this process, manufacturers can ensure high-quality, reliable circuit boards essential for robot functionality.

Automated soldering machines like the Ersa and Juki models have revolutionized PCB production by offering unparalleled speed and accuracy. This automation not only enhances the quality of the final product but also significantly reduces production costs and time. As robots become more sophisticated, the demand for high-quality PCBs continues to grow, making these machines an integral part of the robotics manufacturing ecosystem.

Vision-Guided Robotic Systems

Vision-guided robotic systems combine advanced imaging technology with robotic automation to create highly efficient production processes. These systems use cameras and sensors to guide robots in performing tasks that require visual inspection or orientation adjustments. In the context of robot building, vision-guided systems are used for tasks such as aligning and assembling small components with precision.

By leveraging advanced algorithms and machine learning, these systems can adapt to variations in the production line, ensuring consistent quality. For instance, companies like Cognex and Keyence are leaders in providing vision systems that enhance the capabilities of robots on assembly lines. As technology advances, the integration of vision-guided systems in robot manufacturing will continue to drive innovation and efficiency.

Autonomous Mobile Robot Builders

Autonomous mobile robots (AMRs) are transforming the way factories operate by providing flexibility and efficiency in material handling and assembly processes. These robots can navigate complex environments independently, making them ideal for tasks such as transporting components and assembling modular robot parts on the go.

Companies like Fetch Robotics and MiR are at the forefront of developing AMRs that support robot manufacturing. By integrating sensors and sophisticated navigation software, these robots can adapt to dynamic production environments, ensuring seamless operations. As the demand for more agile and customizable manufacturing solutions grows, AMRs will play a pivotal role in shaping the future of robotics production.

Collaborative Robot Assembly Lines

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety on assembly lines. These robots are equipped with advanced sensors and safety features, making them ideal for tasks that require human-robot interaction. In the realm of robot manufacturing, cobots assist in various assembly processes, from fastening screws to performing quality checks.

One of the significant advantages of cobots is their ability to be easily programmed and reconfigured, allowing manufacturers to adapt quickly to changes in production needs. Companies like Universal Robots and Rethink Robotics are pioneers in developing cobots that support a wide range of industrial applications. With the ongoing advancements in robotics, the role of cobots in building other robots will continue to expand, fostering a collaborative future in manufacturing.

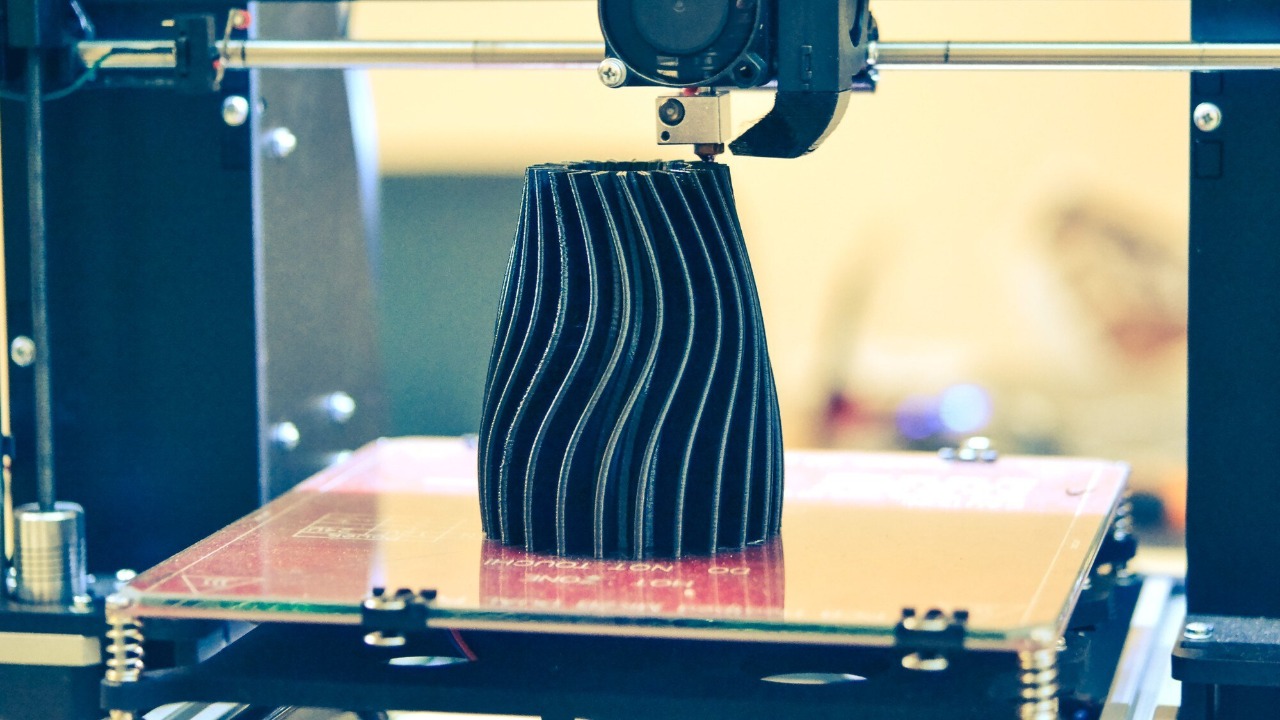

3D Printing Robot Fabricators

3D printing technology has revolutionized manufacturing by enabling the rapid prototyping and production of complex components. In the world of robotics, 3D printing robots are used to fabricate parts with precision and efficiency. These machines can produce intricate designs that would be challenging to achieve with traditional manufacturing methods.

The integration of 3D printing in robot manufacturing allows for greater customization and faster production times. Companies like Stratasys and MakerBot are leading the charge in providing 3D printing solutions that cater to the specific needs of the robotics industry. As the technology evolves, the role of 3D printing robots in building other robots will continue to grow, driving innovation and efficiency in manufacturing.