Ship diesel engines sit at the intersection of brute force and meticulous engineering, turning heavy fuel into the continuous thrust that keeps global trade moving. Among them, a handful of record-setting designs stand out for their staggering power, scale, and, increasingly, their ability to burn cleaner fuels like methanol. Here are five of the most powerful ship diesel engines ever built, from classic low-speed giants to cutting-edge dual-fuel units reshaping what “maximum power” means at sea.

1. The Wärtsilä-Sulzer engine as the most powerful ship engine

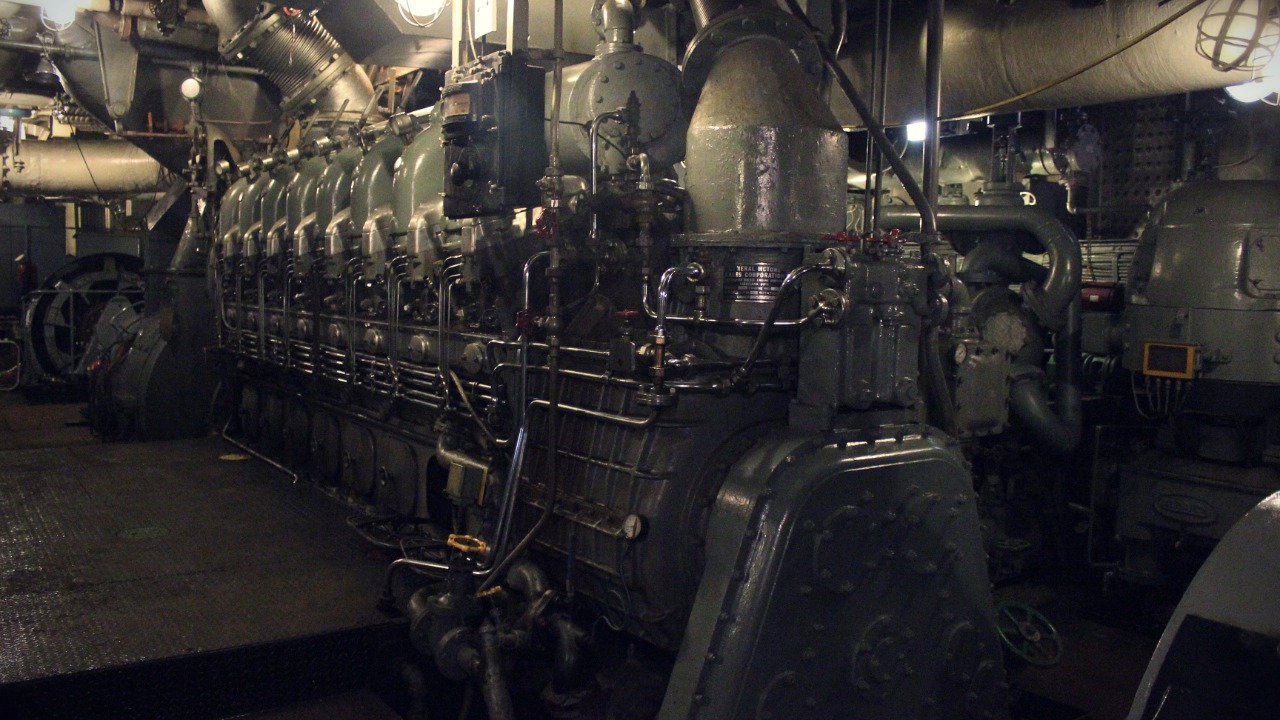

The Wärtsilä-Sulzer RTA96-C is widely recognized as the most powerful ship engine ever installed in commercial service, a low-speed two-stroke diesel built specifically for the largest container vessels. Reporting on the gigantic Wärtsilä-Sulzer highlights how this unit dominates marine propulsion with a scale that dwarfs most industrial machinery. The engine stands 44 feet tall and 89 feet long, and weighs more than 2,300 tons, dimensions that underline why it is often described as the world’s largest marine engine.

Technical references on the Wärtsilä-Sulzer RTA96-C describe a two-stroke, turbocharged, low-speed diesel designed for heavy fuel oil, optimized to push fully loaded container ships at sustained ocean-crossing speeds. Social media engineering explainers further emphasize that this configuration delivers extraordinary torque at low rpm, ideal for directly driving massive propeller shafts without reduction gearing. For shipowners, the stakes are clear, since a single engine of this size can move thousands of containers in one voyage, concentrating both fuel efficiency and emissions responsibility in one colossal powerplant.

2. The 107,390hp (80,080kW) engine as the most powerful diesel ever made

Among all diesel engines, one unit is singled out as the absolute peak in rated output, with coverage describing a marine diesel producing 107,390 hp, or 80,080 kW. Analysts note that this 107,390 hp engine is regarded as the most powerful diesel ever made, a benchmark that places it at the top of any ranking of ship propulsion systems. The figure is not a theoretical maximum but a quoted continuous rating, which matters for vessels that must maintain high speeds for weeks at sea.

Context from broader roundups of powerful ship diesels shows how this rating eclipses other large two-stroke designs that already operate at tens of thousands of horsepower. For naval architects and operators, such output allows very large container ships or tankers to meet tight schedules without resorting to multiple main engines, simplifying shaft-line design and maintenance. The trade-off is that any incremental efficiency gain or emissions reduction at this power level has an outsized impact on fuel bills and regulatory compliance.

3. The world’s most powerful piston engine and its ship

The world’s most powerful piston engine built specifically for a ship is profiled in detail in coverage of the largest piston engine, which focuses on a low-speed marine diesel whose individual cylinders are themselves the size of small rooms. This engine is described as a record-setting piston design, emphasizing that each cylinder uses a conventional piston and connecting rod rather than turbine or electric-hybrid technology. The reporting pairs the engine with the ship it was designed for, underscoring how hull form, propeller, and powerplant were engineered as a single system.

Unlike smaller high-speed diesels used in fishing boats or yachts, this giant piston engine operates at very low rpm, trading revs for immense torque. That approach aligns with the priorities seen in lists of top diesel marine engines, where reliability and fuel burn per mile matter more than peak rpm. For cargo operators, the implication is that piston-based low-speed diesels remain the backbone of deep-sea shipping, even as alternative fuels and hybrid systems gain attention, because their mechanical simplicity and proven durability still underpin global logistics.

4. The world’s most powerful methanol engine for marine power

The world’s most powerful methanol engine for marine power marks a turning point, combining very high output with a cleaner-burning fuel. Reporting on this development describes a large marine unit configured as a dual-fuel system that can run on conventional diesel or methanol, with the methanol mode significantly reducing sulfur and particulate emissions. Coverage of this methanol engine stresses that it is aimed squarely at oceangoing ships, not small coastal craft, signaling that alternative fuels are moving into the deep-sea segment.

Technical summaries explain that the engine’s methanol capability is layered onto a familiar low-speed diesel architecture, allowing operators to retain existing maintenance expertise while shifting fuel strategy. That compatibility is crucial for shipowners facing tightening emissions rules but wary of unproven propulsion concepts. By offering high power with dual-fuel flexibility, this engine shows how the industry can decarbonize incrementally, using methanol infrastructure where available while falling back on diesel in regions that lack alternative bunkering.

5. The world’s most powerful methanol dual-fuel engine by MAN ES

The MAN B&W 12G95ME-C10.5-LGIM is identified as the world’s most powerful methanol dual-fuel engine, with a reported output of 82,440 kW. A detailed technical overview of this MAN LGIM engine explains that it uses MAN’s LGIM (Liquid Gas Injection Methanol) technology to inject methanol directly while retaining full diesel capability. Separate industry reporting notes that this methanol dual-fuel engine is poised to be delivered for commercial service, underlining that it is not just a prototype.

By pairing very high power with dual-fuel flexibility, the 12G95ME-C10.5-LGIM gives large ship operators a way to meet emissions targets without abandoning proven two-stroke diesel platforms. The stakes are significant for charterers and cargo owners, since vessels equipped with such engines can access ports with stricter environmental rules while still operating globally. In practical terms, this design shows how the definition of “most powerful ship diesel” is evolving, now encompassing engines that deliver both raw output and a pathway to lower-carbon operation.

More from MorningOverview