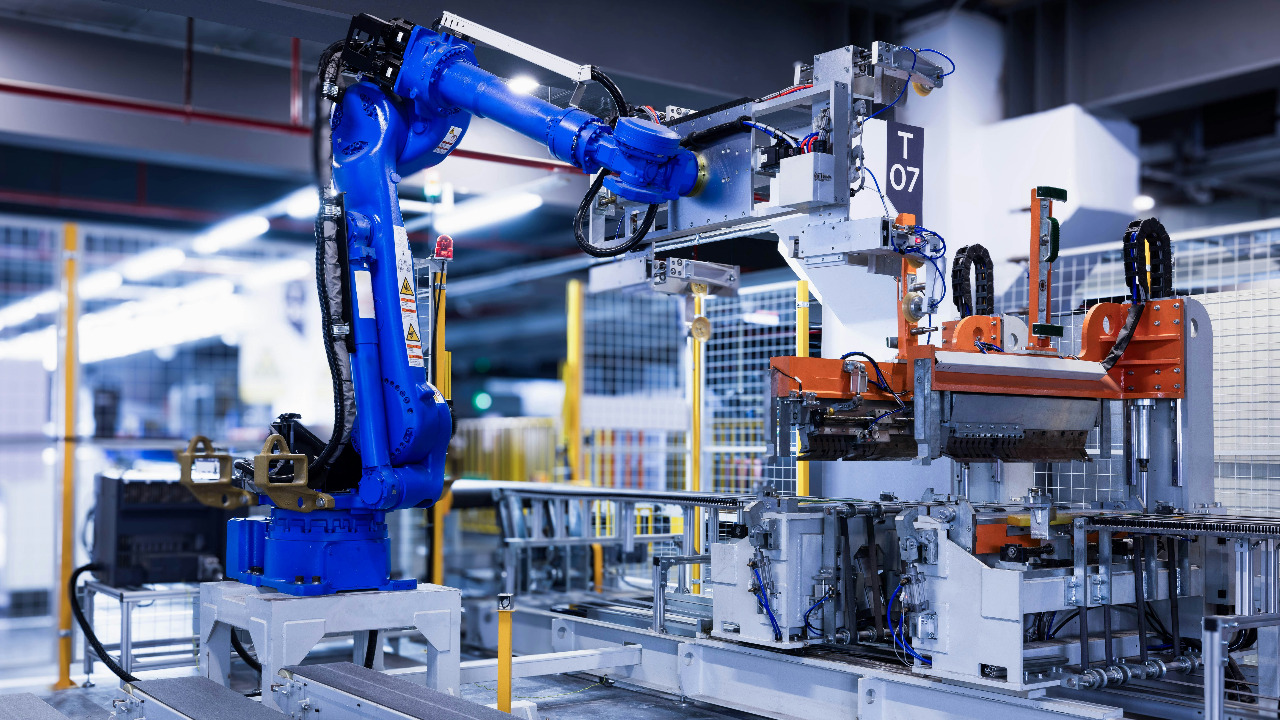

With the rapid evolution of technology, robots are becoming a staple in modern factories. Their integration is driven by various compelling factors that promise to revolutionize the manufacturing landscape. Here are ten reasons why robots are increasingly being employed in factories.

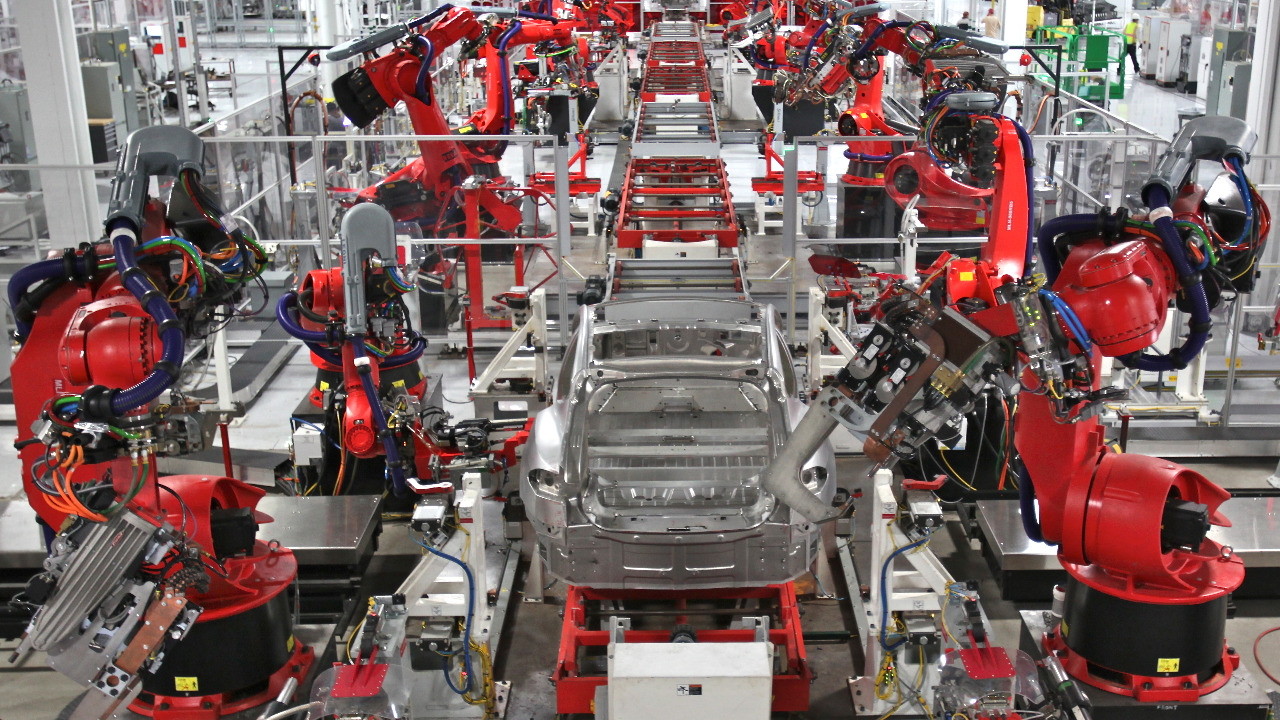

1. Increased Efficiency

One of the primary reasons robots are being introduced into factories is their ability to significantly enhance efficiency. Unlike human workers, robots do not require breaks, and they can work continuously around the clock. This leads to faster production times and the ability to meet high demand without compromising on efficiency. For instance, in the automotive industry, robots can assemble vehicles like the Tesla Model 3 more swiftly than human workers.

Additionally, robots are less prone to fatigue-related errors, ensuring a steady pace of work. This continuous operation and minimal downtime directly contribute to increased throughput and productivity.

2. Cost Reduction

Although the initial investment in robotic systems can be substantial, the long-term cost savings are significant. Robots help reduce labor costs by handling tasks that would otherwise require a large workforce. For example, in electronics manufacturing, robots are used to assemble small and intricate components, reducing the need for manual labor.

Moreover, robots minimize the likelihood of costly errors and waste, thereby optimizing resource utilization. This reduction in errors and waste can lead to considerable financial savings over time.

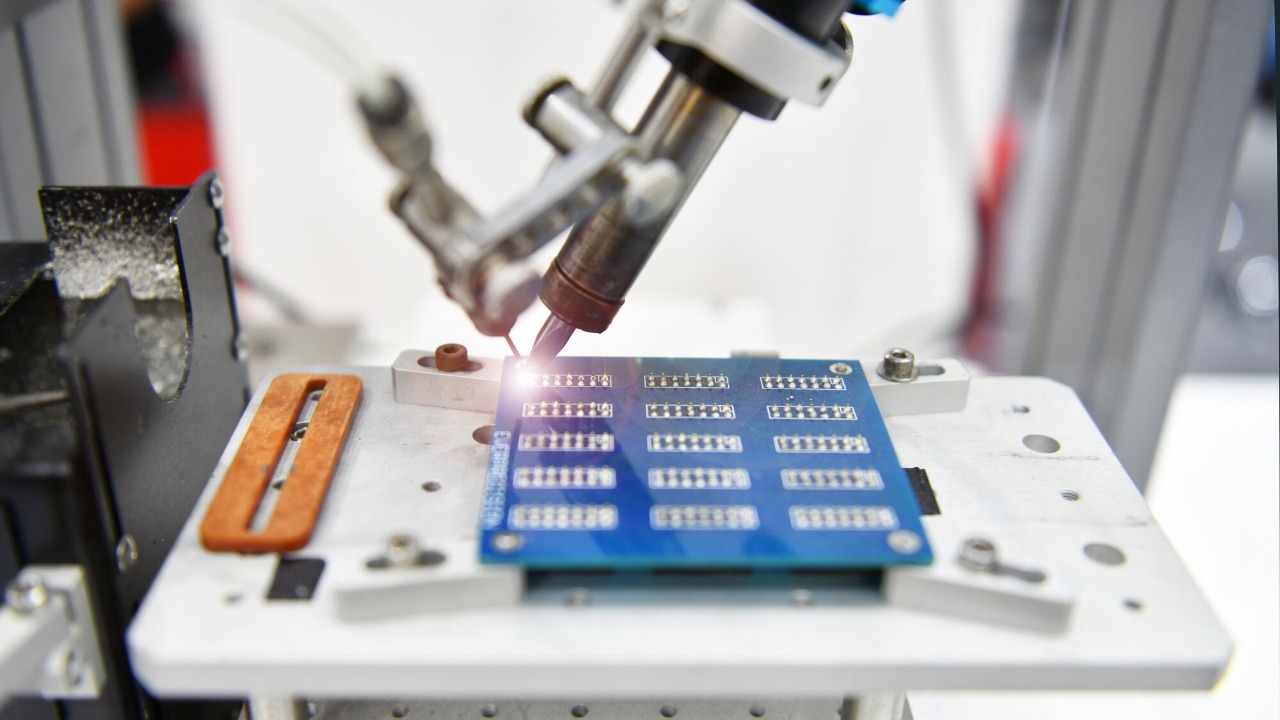

3. Enhanced Precision

Robots are known for their precision and accuracy, which are unmatched by human workers. This level of precision is crucial in industries such as pharmaceuticals and electronics, where even the smallest error can lead to significant issues. For example, in semiconductor manufacturing, robots are used for tasks requiring micrometer-level accuracy.

The use of robots ensures that products are manufactured to exact specifications, reducing the need for rework and enhancing overall product quality.

4. Improved Safety

Safety is a key consideration in manufacturing environments, and robots play a vital role in enhancing workplace safety. By taking on dangerous tasks, such as handling hazardous materials or operating in extreme temperatures, robots help protect human workers from potential injuries.

This shift not only reduces the number of workplace accidents but also helps companies comply with safety regulations. Research shows that automation in factories can lead to safer work environments.

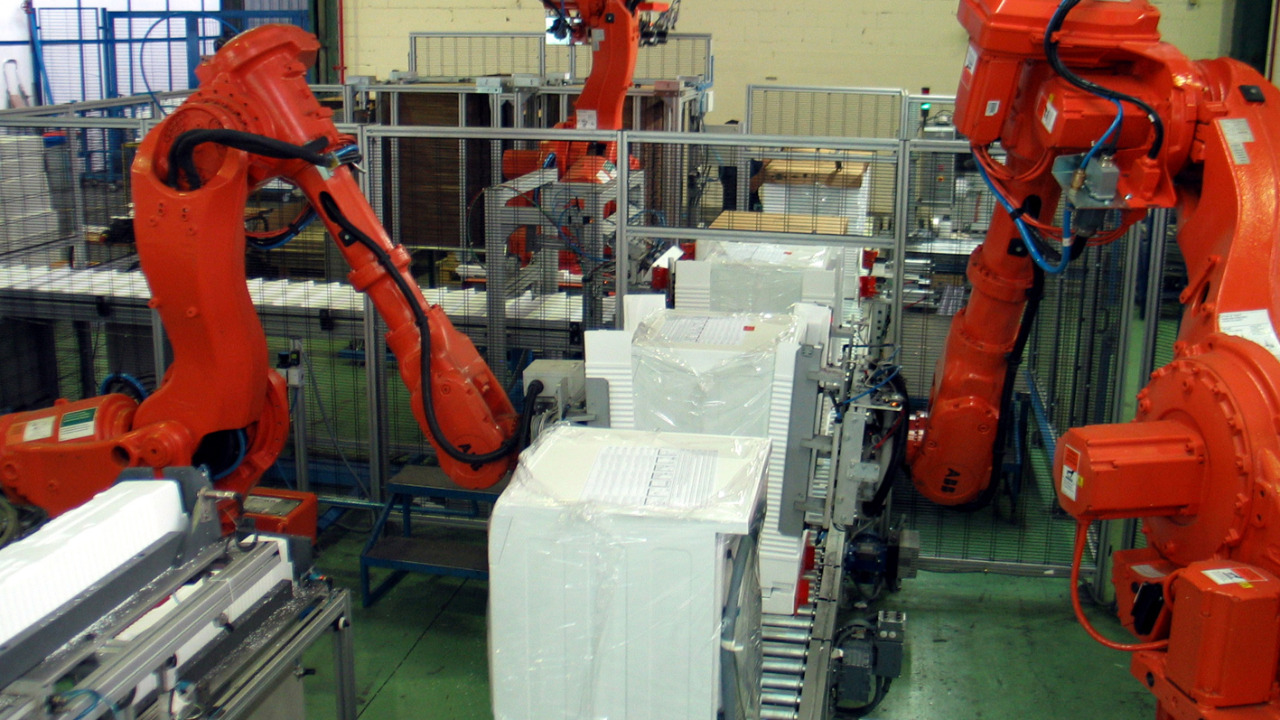

5. Consistent Quality

Robots are capable of delivering consistent quality, which is essential for maintaining brand reputation and customer satisfaction. In industries like food and beverage, where consistency is key, robots ensure that each product meets the same quality standards.

By eliminating human error and variability, robots help maintain uniformity in production, leading to fewer defects and recalls. This consistency is a major factor in why companies are investing in robotic technology.

6. Labor Shortages

The manufacturing sector often faces challenges related to labor shortages, particularly in regions where the workforce is aging or where there is a lack of skilled workers. Robots can help bridge this gap by performing tasks that are difficult to fill with human labor.

For instance, in the textile industry, robots are increasingly being used to automate the sewing process, which is traditionally labor-intensive. Automation helps mitigate the impact of labor shortages and ensures that production can continue without disruptions.

7. Advanced Technology

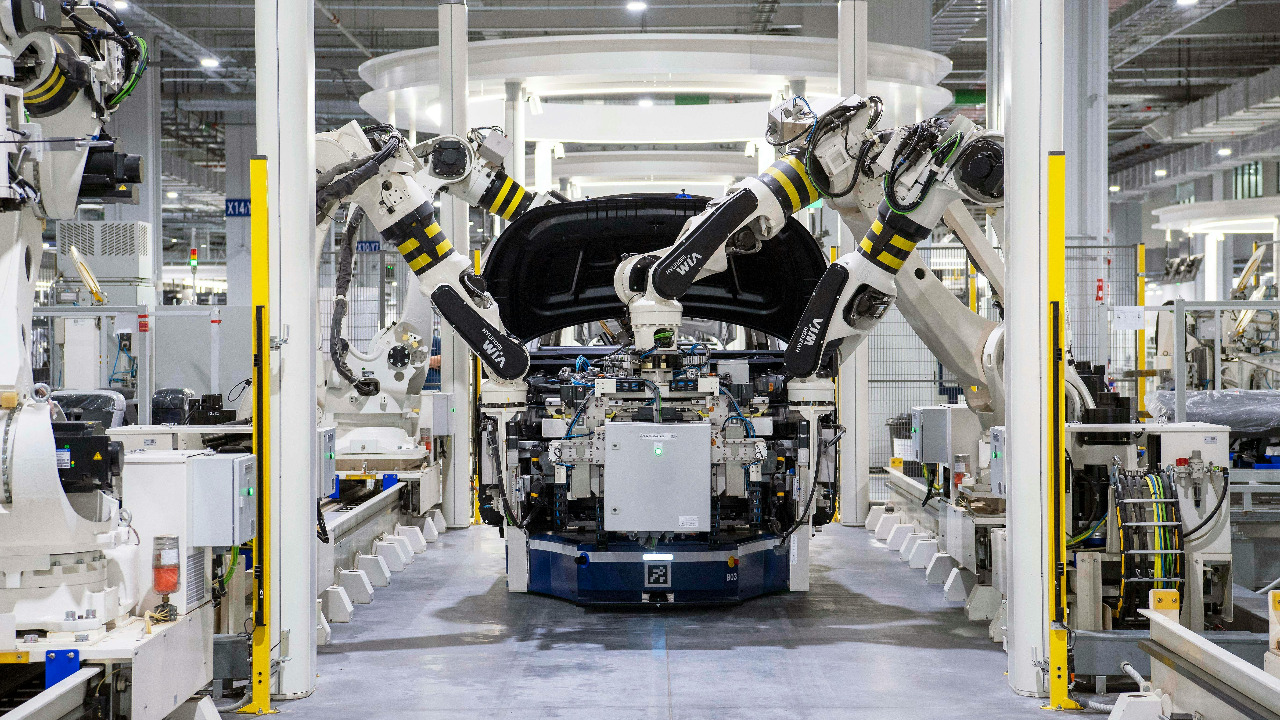

Advancements in technology have made robots more capable and versatile than ever before. With the integration of artificial intelligence and machine learning, robots can perform complex tasks and adapt to new situations with ease.

For example, collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and efficiency. These technological advancements are a major driver of the increased adoption of robots in factories.

8. Flexibility and Adaptability

Modern robots offer a high degree of flexibility and adaptability, allowing manufacturers to quickly reconfigure production lines to accommodate new products or changes in demand. This is particularly valuable in industries with rapidly changing markets, such as consumer electronics.

By enabling quick and efficient transitions, robots help companies remain agile and responsive to market trends. This flexibility is a crucial advantage in today’s fast-paced manufacturing landscape.

9. Enhanced Data Collection

Robotic systems are equipped with sensors and software that enable them to collect and analyze vast amounts of data. This data can be used to monitor production processes, identify inefficiencies, and implement improvements.

For example, in the automotive industry, robots gather data during assembly to ensure quality control and optimize operations. This data-driven approach enhances overall manufacturing performance and decision-making.

10. Global Competitiveness

In an increasingly competitive global market, the adoption of robotic technology is essential for manufacturers looking to maintain a competitive edge. Robots enable companies to produce high-quality products at lower costs, making them more competitive on the world stage.

By investing in robotics, manufacturers can improve their production capabilities and efficiency, which is vital for thriving in a global economy. According to industry experts, embracing automation is a key strategy for enhancing global competitiveness.