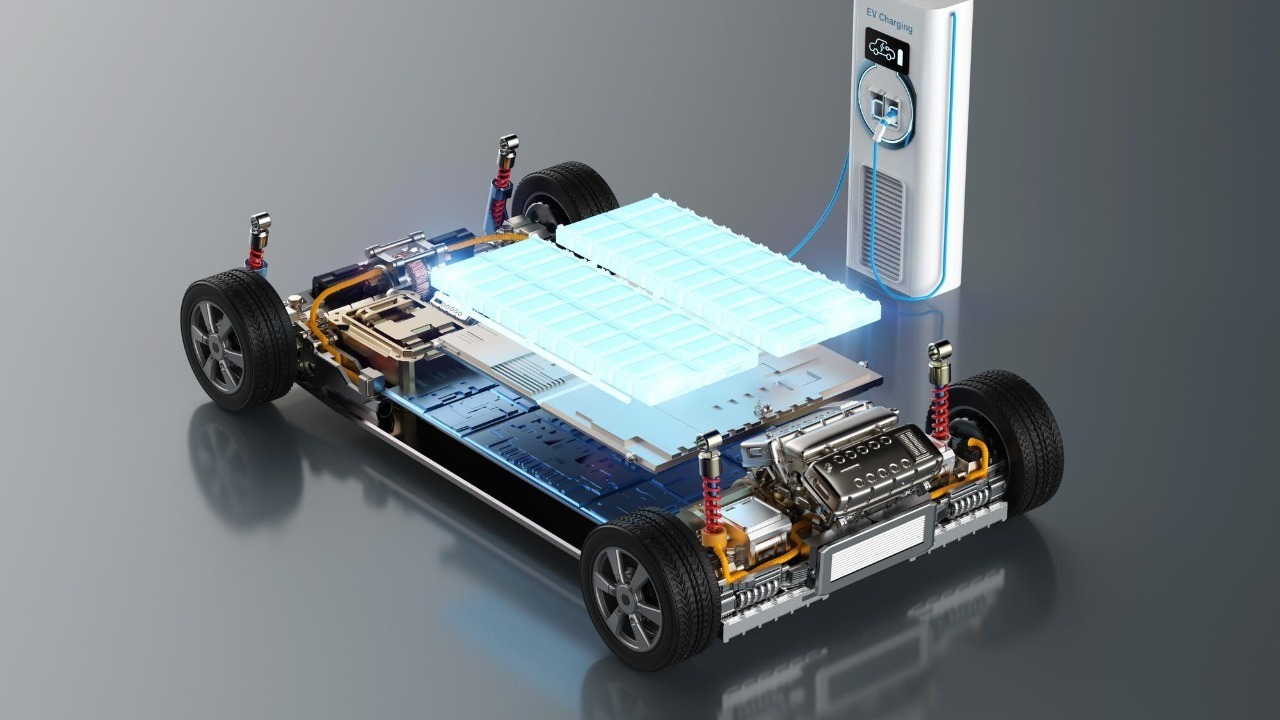

Electric vehicles are on the cusp of a battery shake‑up that could matter more than any styling tweak or software update. A major Tech company has now trailed plans for a 2026 debut of a radically different pack, described as a world’s first of its kind, promising faster charging and cheaper materials that could undercut today’s lithium‑ion cells. I see that claim landing in an industry already racing to commercialize solid‑state, silicon‑rich, and sodium‑ion chemistries, which together are redefining what an EV battery can be.

Rather than a single moonshot, the 2026 timeline sits inside a broader wave of overlapping breakthroughs. From Chinese manufacturers scaling sodium‑ion cells to Huawei’s long‑range solid‑state concepts and SAMSUNG SDI’s award‑winning cylindrical designs, the competitive pressure is intense. That context is crucial for judging how transformative this Tech giant’s teased battery might really be once it reaches showrooms.

Inside the ‘first‑of‑its‑kind’ 2026 battery tease

The Tech company’s 2026 plan centers on a pack that swaps scarce ingredients for more abundant ones while still promising fast charging and robust range. In public hints, the firm has framed it as a world’s first in mass‑market EVs, aligning with reporting that a Tech giant intends to launch a first‑of‑its‑kind battery in 2026 and that “the tech is speeding along,” a description that fits the rapid progress around Tech. I read that positioning as a bet on chemistry that can tolerate frequent rapid charging without the degradation that plagues many current packs, which is one of the main reasons drivers still worry about battery longevity.

To understand why this matters, it helps to recall how today’s packs behave over time. Standard lithium‑ion EV batteries, as explained by insurance specialist Cann in a primer on What an Electric car battery actually is, are engineered to last for years but still lose capacity with each cycle. The Tech company’s 2026 design is pitched as a structural break from that pattern, using a chemistry that should be less sensitive to repeated fast charges and high‑power discharge. If it delivers, that would not just extend usable life, it would also allow automakers to shrink pack sizes without triggering range anxiety, cutting cost and weight at the same time.

Solid‑state, silicon and sodium: the crowded race to 2026

The Tech giant’s move does not happen in a vacuum. In China, Several automakers have already shown solid‑state and semi‑solid prototype packs, with limited semi‑solid systems on sale in select markets, according to detailed reporting on prototype development. A companion analysis of the same Chinese push notes that major international brands are targeting 2026 for broader solid‑state launches, with energy densities far above most conventional lithium‑ion packs, underscoring how crowded the 2026 launch window has become.

Huawei is pushing that frontier from another angle. The company has claimed that a new solid‑state EV battery could drive over 20000 miles (3000 km) on a charge and refill in five minutes, according to a detailed breakdown of Huawei’s patent work. A separate technical video on the same nitrogen sulfide based design notes that Huawei’s concept targets between 400 and 500 watt‑hours per kilogram, figures that, if achieved, would dwarf many current cells and could, as one analysis of Huawei’s 3000 km concept puts it, threaten to leapfrog rivals like Toyota. Another explainer on Huawei’s patent, framed around a 5‑minute charge and 1864 mile range, stresses that this is not the only car company working on solid‑state EV batteries, but it is the only one with anything close to those Jun metrics on paper.

On the road today, solid‑state is already edging into real‑world use. Donut Battery, highlighted in a widely watched teardown, is described as the world’s first solid‑state battery in production vehicles shipping to customers, with a video from Donut Battery walking through the pack’s construction. In a separate lab‑style explainer, Donut Lab CEO Marko Lehtimaki, speaking in a segment that also plugs the Ascentiz Exoskeleton, gives a detailed rundown of the Donut Batt architecture and how it differs from conventional cells, illustrating in practical terms how Check this chemistry is already moving from hype to hardware.

Legacy automakers are racing to keep pace. Stellantis has said it will field a Demonstration Fleet of all‑new Dodge Charger Daytona vehicles by 2026 equipped with solid‑state packs, a commitment detailed in coverage of the Demonstration Fleet. That timeline overlaps directly with the Tech giant’s 2026 target, which is why I see the coming year as a stress test for whether solid‑state can scale beyond niche runs and into mainstream muscle cars and crossovers.

At the same time, silicon‑rich anodes are quietly reshaping expectations for conventional cells. A detailed technical brief on the silicon battery breakthrough argues that 2026 will see the first large‑scale deployment of silicon batteries in EVs, with higher energy density and better fast‑charge performance than today’s graphite‑based packs, a shift that one analysis of Jan trends says will make packs look and perform less alike. Another explainer on silicon‑carbon technology notes that by replacing heavier graphite with much lighter silicon, battery makers can reduce battery size and vehicle weight without sacrificing range, a change that could make EV ownership more affordable, as detailed in a breakdown of Jan silicon‑carbon advances.

More from Morning Overview