MacPherson struts went from an engineering curiosity to the default front suspension on everyday cars because they solved several problems at once: cost, packaging, and compatibility with modern body structures. Instead of chasing ultimate handling precision, automakers prioritized a layout that was cheap to build, easy to package in small cars, and good enough for the way most people actually drive.

To understand why so many brands abandoned bulkier double wishbones and other complex layouts, I need to trace how the MacPherson idea fit perfectly with unibody construction, front wheel drive, and the relentless pressure to cut manufacturing costs. The story is less about a single breakthrough and more about a design that kept lining up with every new priority the industry set for itself.

How the MacPherson strut changed the basic suspension recipe

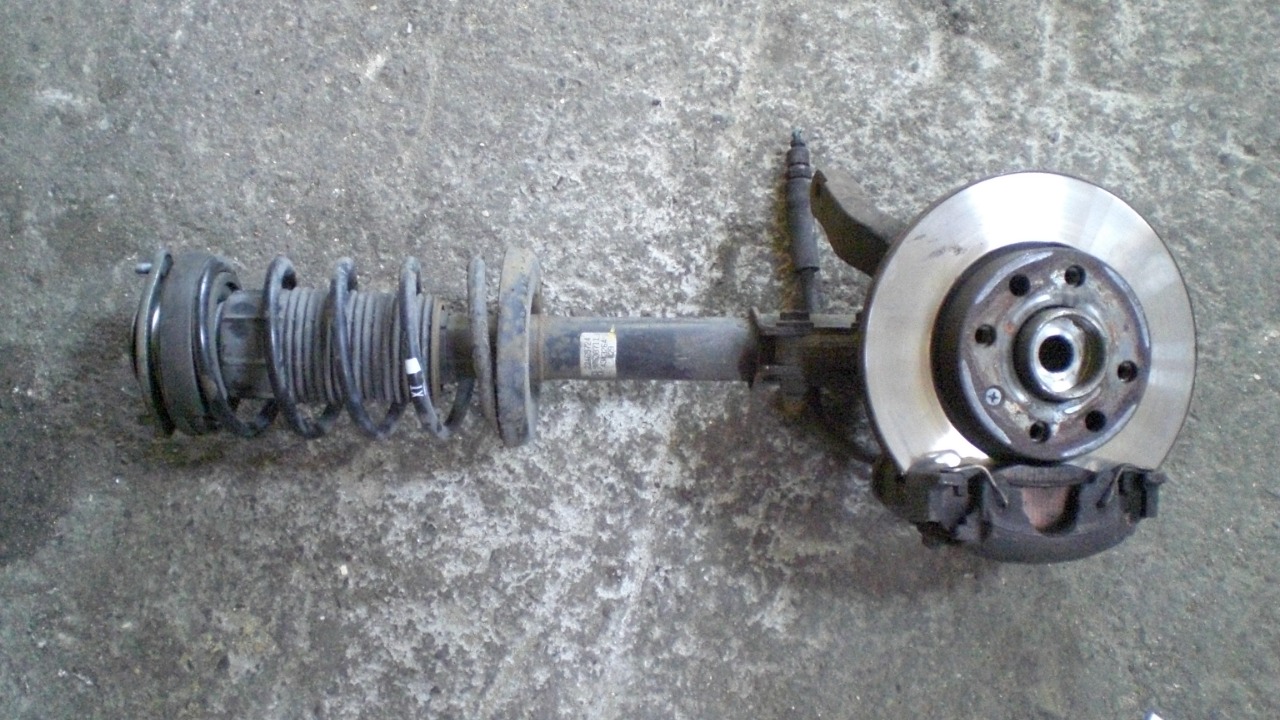

The MacPherson layout simplified the front suspension by combining the damper and spring into a single structural unit that also locates the wheel in space. Instead of a maze of arms and links, the strut ties the wheel hub to the body at the top and to a single lower control arm at the bottom, which is why a typical front corner can be removed as one compact assembly. That basic architecture is what people are referring to when they talk about a MacPherson strut suspension, and it is the reason the term can describe both the physical strut and the overall system that surrounds it.

Because the strut itself carries the spring and guides the wheel, it reduces the number of separate parts compared with older layouts that used upper and lower arms plus a separate shock. Technical explainers describe a MacPherson strut suspension as a simple independent design that uses a tall damper body, a coil spring, and a lower arm to control wheel motion, with the body structure providing the upper mounting point for the assembly, which is why a modern definition of What Is a MacPherson Strut Suspension, Plus Other Related FAQs, emphasizes that simplicity as its core trait.

Why cost and manufacturing efficiency pushed automakers toward struts

Automakers did not flock to MacPherson struts because they were the most exotic or sophisticated option, they did it because the layout was cheaper to build at scale. By folding the spring and damper into one structural unit and eliminating an upper control arm, the design cut down on steel, bushings, and assembly steps. For a mass market manufacturer building hundreds of thousands of compact cars, shaving even a small amount of material and labor from each front corner translated into serious savings.

Analyses of the shift toward this layout point out that the main attraction was its low cost and compact packaging, which made it ideal for high volume models where every dollar counts, a point that is spelled out in detail in a Dec feature titled Why Did Automakers Start To Use Struts. When I look at how aggressively manufacturers chase economies of scale, it is clear that a suspension layout that can be stamped, welded, and bolted together with fewer unique parts was always going to be attractive, even if it meant accepting some compromises in ultimate handling precision.

The role of unibody construction in making struts the default

The rise of unibody construction did as much to cement the MacPherson layout as any suspension engineer. Once carmakers moved away from separate frames and started using the body shell as the main load bearing structure, they suddenly had strong towers in the front corners that could anchor a tall strut. That meant the body itself could carry suspension loads, which played directly into the strengths of a design that needs a rigid upper mount to work properly.

Technical references on the layout note that unibody construction distributes suspension stresses through the shell and that the strut usually carries both the coil spring and the damper, with the body providing the upper attachment point, which is why the Unibody era is so closely tied to the spread of MacPherson designs. Once manufacturers had invested in stamping body structures with integrated towers, it became even harder to justify the extra complexity of double wishbones that needed more space and more separate mounting points.

Packaging advantages in small cars and front wheel drive layouts

As cars shrank and front wheel drive took over, the MacPherson layout solved a packaging puzzle that other suspensions struggled with. A tall, narrow strut leaves more room in the engine bay for transverse powertrains, steering racks, and crash structures, which is critical in compact hatchbacks and sedans. By keeping the hardware close to the wheelhouse, engineers could design shorter overhangs and lower hoods without sacrificing basic wheel travel.

Modern explainers on the design highlight that one of the most significant advantages of MacPherson struts is how little space they take up compared with double wishbone or multi link systems, which is why they are so common in compact and mid size cars that need every millimeter of room under the hood, a point that is spelled out in a Feb guide that notes this packaging edge with a telling “However” when comparing them to more complex layouts in performance cars, as seen in MacPherson strut suspension explained. When I look at popular coupes and compact models, from an Audi TT to a BMW 4 Series, I see how that space saving advantage lets designers carve out cabins where They have two seats in the front and two smaller seats in the back, a layout that is described in detail in a guide to They different car types.

How the design fits the way most people actually drive

For everyday drivers, the priority is not shaving tenths off a lap time, it is comfort, predictability, and low running costs. The MacPherson layout delivers a compliant ride and stable handling that is more than adequate for commuting, school runs, and highway trips, especially when paired with modern tires and electronic stability systems. That balance between comfort and control is one reason so many mainstream models, from compact crossovers to family sedans, rely on this setup at the front.

Consumer focused explainers emphasize that Your car’s suspension is engineered to soak up bumps and keep the vehicle stable, and they note that many cars on sale today use MacPherson struts precisely because they hit that sweet spot between cost and capability, a point made clearly in a Jan overview that explains why Your typical daily driver is built this way. When I compare that to the more complex double wishbone or multi link setups used in high end sports cars, it is obvious that most buyers are willing to trade a bit of ultimate grip for a smoother ride and a lower sticker price.

Why performance purists still argue for double wishbones

Even as MacPherson struts conquered the mass market, performance engineers and enthusiasts kept pointing out their limitations. Because the strut uses a single upper mount, it can struggle to maintain ideal camber angles as the suspension moves, which affects how the tire contacts the road under hard cornering. Double wishbone and multi link systems, with their separate upper and lower arms, give designers more control over wheel geometry, which is why they remain the go to choice for track focused models.

Technical comparisons note that conventional wisdom still favors double wishbones for high performance cars, even as MacPherson layouts have improved with better bushings and geometry, and that tension is spelled out in a Feb analysis that contrasts the simple strut with more complex alternatives in However detailed terms. I see that split reflected in the market, where everyday hatchbacks and crossovers rely on MacPherson fronts while halo sports cars and some luxury sedans still invest in multi link or double wishbone setups to squeeze out every last bit of grip and steering feel.

Serviceability and ownership: how struts changed repair culture

From a mechanic’s perspective, the MacPherson layout reshaped how front end repairs are done. Because the spring, damper, and upper mount are integrated, a worn assembly can often be removed and replaced as a single unit, which simplifies labor and reduces the chance of misaligning separate components. That modularity also made it easier for aftermarket suppliers to offer complete replacement kits, which in turn helped keep older cars on the road longer.

Technical guides on the design point out that one advantage of MacPherson struts is that the entire corner can be removed as a single unit, which streamlines both factory assembly and later service, a detail spelled out in a Sep explainer titled What Strut. When I talk to independent shops, they often note that while replacing a complete strut assembly can be more expensive in parts than just swapping a shock, the labor savings and predictability make it a fair trade for many owners who value quick, straightforward repairs.

Global adoption: why emerging markets embraced MacPherson struts

The appeal of MacPherson struts is not limited to Europe, Japan, or North America, it is also deeply embedded in fast growing markets where affordability is paramount. In countries where buyers prioritize low purchase prices and reasonable maintenance costs, a simple front suspension that can be built cheaply and serviced easily is a major advantage. That is one reason compact hatchbacks and sedans in these regions so often share the same basic front layout, even when they come from different brands.

Market research on the India Automotive Suspension Market notes that Its MacPherson strut simple and cost effective design makes it a popular choice, especially in segments where price sensitivity is high and the layout suits the economic preferences of Indian consumers, a point spelled out in detail in an industry report on Its suspension trends. When I look at how global platforms are shared across regions, it is clear that once a manufacturer commits to a MacPherson front end for a cost sensitive market, that same architecture often carries over to more expensive trims and export models as well.

Why the design has endured despite newer alternatives

Given how long the MacPherson layout has been around, it is striking how little its core concept has changed. Engineers have refined geometry, bushings, and materials, but the basic idea of a tall strut carrying the spring and damper between the wheel and the body remains intact. That longevity suggests the design hit a sweet spot that newer alternatives have struggled to dislodge, especially in the crowded middle of the market where cost and packaging still dominate the spec sheet.

Historical overviews note that the MacPherson strut solution gave automakers a way to build independent front suspensions that were compact, cheap, and robust enough to survive decades of evolution, which is why it has survived all these years as one of the most common layouts on the road, a point highlighted in a Sep piece that lists Sep facts about the design. Modern summaries echo that view, noting that the MacPherson suspension is now one of the most common suspension forms today and outlining the features and benefits that keep it relevant, as seen in a Jan explainer titled What Macpherson Strut Suspension, How Does It Work, Home, News.

What the MacPherson era means for the next generation of cars

As electrification and advanced driver assistance reshape vehicle platforms, the same forces that once favored MacPherson struts are resurfacing in new forms. Electric motors, battery packs, and sensor suites all compete for space, and engineers still need a front suspension that is compact, predictable, and compatible with stiff unibody structures. That makes it likely that the basic strut layout will continue to appear in front axles, even as rear suspensions evolve toward more complex multi link designs to manage heavy battery packs and deliver refined ride quality.

Technical FAQs on modern layouts stress that a MacPherson strut suspension remains a simple independent design that is easy to integrate into a wide range of vehicles, from small hatchbacks to crossovers, which is why guides like Strut Suspension Plus Other Related explanations still treat it as the default reference point. When I look across the industry, from budget city cars to premium coupes, I see a pattern that started decades ago and shows no sign of reversing: whenever automakers face a new packaging or cost challenge, they keep coming back to the same tall, simple strut that quietly reshaped how modern cars ride and handle.

More from MorningOverview