US researchers have quietly crossed a threshold in nuclear materials science, using intense neutron beams to peer inside TRISO fuel particles that were once effectively opaque to direct measurement. The work, long constrained by classification and experimental limits, is now surfacing in public as part of a broader push to commercialize high‑temperature reactors and rebuild the domestic fuel supply chain. Together, the new measurements and the parallel industrial build‑out suggest that TRISO fuel is moving from laboratory promise to a central pillar of the next US nuclear era.

At the heart of the story is a deceptively simple question with high stakes for safety and cost: what exactly happens inside a TRISO particle as it burns in a reactor for years at extreme temperatures. By combining advanced neutron scattering with a surge of federal investment in HALEU and uranium enrichment, US scientists and companies are starting to answer that question in real time, with implications that reach from experimental test loops to full‑scale power plants.

Neutron beams crack open TRISO’s black box

For decades, TRISO fuel has been marketed as “accident tolerant,” yet much of its internal chemistry remained inferred rather than observed. Recent work at national laboratories has changed that, using New scattering experiments to illuminate how fission products move and react inside the tiny fuel kernels and their ceramic and carbon shells. Those measurements are particularly important for high‑temperature gas reactors, or HTGRs, where fuel must endure temperatures far beyond those in today’s light‑water plants without releasing radioactivity. By tracking subtle structural and chemical shifts, scientists can now validate or challenge long‑standing models of how TRISO behaves under stress.

The same campaign has been described as a way to reveal “hard‑to‑detect chemistry” inside novel fuels, with Feb work highlighting how neutron scattering can map the distribution of key elements that influence swelling, cracking, and gas retention. A related report emphasizes that these Published experiments give designers a direct handle on how the particle’s multiple layers share mechanical loads and trap fission gases over time. In practical terms, that means regulators and vendors can move from conservative guesswork to data‑driven limits on burnup and temperature, potentially unlocking more energy from each batch of fuel without sacrificing safety margins.

Inside the “first of its kind” TRISO neutron experiment

The most striking step forward came in what researchers have described as a first‑of‑its‑kind neutron scattering experiment on HALEU‑based TRISO fuel. A US team used intense beams at the Spallatio source to probe how the fuel’s enriched uranium kernel interacts with its surrounding layers of ceramic and carbon. By varying temperature and irradiation conditions, they could watch in unprecedented detail how stresses build up in the coatings that are supposed to keep fission products locked away. That level of resolution is critical for HALEU TRISO, which packs more fissile material into each particle and therefore faces more intense internal pressures.

Reporting on the same campaign underscores that, in a first, the US group used neutron beams to unveil secrets of TRISO fuel that had previously been accessible only through destructive post‑irradiation exams. A separate account of the same work notes that the Spallatio facility allowed researchers to interrogate the layered structure without cutting into the particles, preserving the very gradients they wanted to measure. In my view, that non‑destructive capability is what makes this feel like a classified‑grade diagnostic finally entering the open toolkit of civilian nuclear engineering.

Neutron scattering as a design tool, not just a diagnostic

What makes these experiments more than a scientific curiosity is how they feed directly into fuel design and qualification. One summary of the work stresses that Neutron scattering illuminates how microscopic TRISO particles respond to heat and irradiation, giving engineers a direct link between processing conditions and in‑reactor performance. By correlating scattering signatures with later destructive exams, teams at ORNL and partner labs can refine fabrication recipes to minimize defects that might otherwise only show up after years of operation. That shortens the feedback loop from experiment to commercial fuel line, a key bottleneck for advanced reactors.

Another account of the same program emphasizes that the technique gives a “peek” into the microscopic TRISO particles that goes beyond simple imaging, revealing how composition and microstructure evolve together. That dovetails with the earlier New scattering work on HTGR fuels, which framed neutron techniques as a way to tune fuel for specific reactor concepts rather than treating it as a one‑size‑fits‑all commodity. As I see it, that shift, from post‑hoc inspection to active design tool, is what will let vendors push toward higher outlet temperatures and longer fuel cycles without flying blind.

HALEU, enrichment and the TRISO supply chain

The science would matter far less if there were no fuel to put into reactors, which is why the parallel policy moves around HALEU and enrichment are so significant. The Department of Energy has laid out plans to Distribute Next Round to the US Nuclear Industry, explicitly naming Antares Nuclear, Inc as a recipient for its advanced reactor program. A companion announcement describes how the Department of Energy is structuring these allocations to seed multiple designs rather than backing a single winner, a strategy meant to avoid the boom‑and‑bust cycles that have plagued past nuclear initiatives. In practice, that means TRISO developers can plan multi‑year test campaigns with some confidence that enriched feedstock will be available.

On the enrichment side, the federal government has committed $2.7 Billion under a program titled Restore American Uranium, with the Department of Energy framing it as a way to rebuild domestic capacity that had atrophied after years of reliance on foreign suppliers. A related policy analysis notes that in 2026 the DOE awarded three companies, American Centrifuge Operating, General Matter, and Orano Federal Services, $900 m each, explicitly described as $900 million, to support enrichment for both reactors and high‑tech industries. That scale of funding signals that HALEU supply is being treated as strategic infrastructure, not a niche experiment.

Standard Nuclear and the race to scale TRISO production

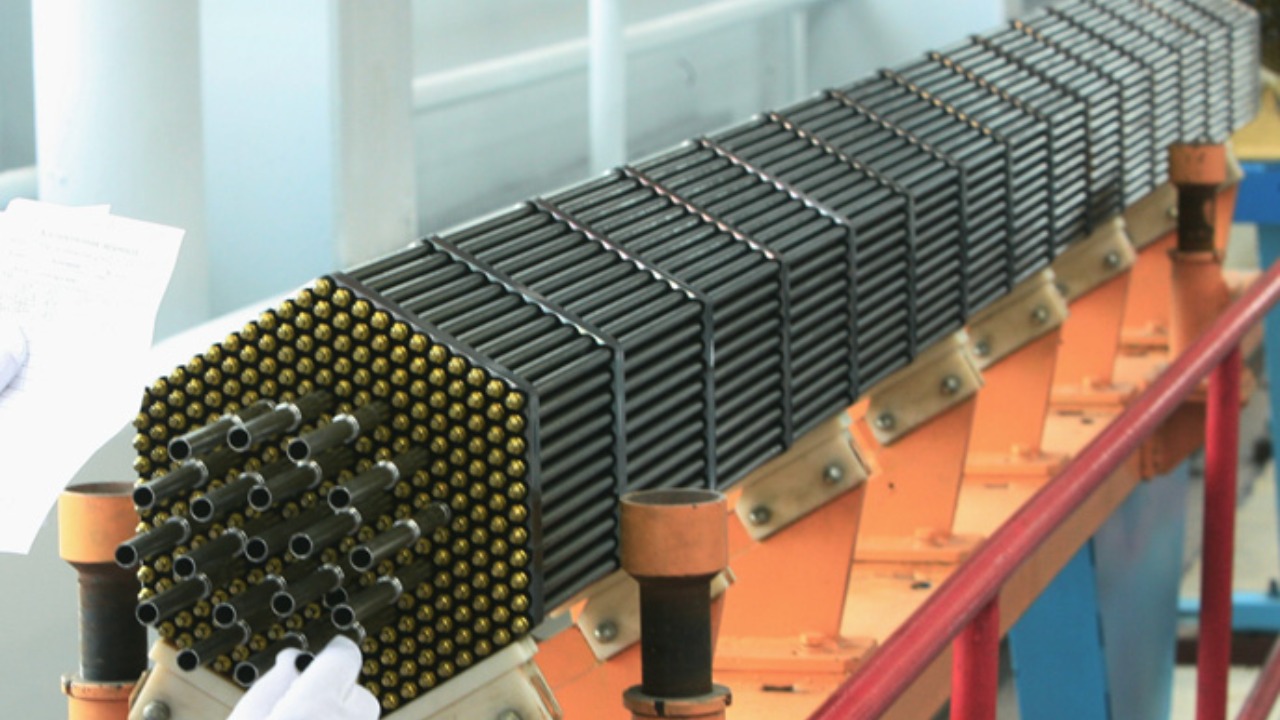

On the industrial front, Standard Nuclear has emerged as an early mover in turning TRISO from a lab product into a commercial fuel line. A business announcement from BUSINESS WIRE notes that Standard Nuclear, Inc, based in OAK RIDGE, Tenn, became the first private company to receive HALEU feedstock specifically for TRISO production, positioning itself as a reactor‑agnostic supplier to multiple designs. A follow‑up report explains that the company’s role fits into a broader strategy to harden critical supply chains, including nuclear energy, by anchoring fuel fabrication near national lab expertise in Oak Ridge.

Standard Nuclear’s production plans are ambitious. Industry coverage notes that the company has started TRISO manufacturing and intends to expand capacity to more than 2 tonnes by mid‑2026, with an Image credit explicitly tying the ramp‑up to pilot reactors scheduled for 2026. A separate note on the same development refers to Standard Nucle as a key participant in the DOE’s fuel line pilot program, which is described elsewhere as Supporting the Reactor Pilot Program by de‑risking private investment and commercial‑scale deployment. In my assessment, that alignment between cutting‑edge neutron diagnostics and a rapidly scaling TRISO factory is what turns a classified‑style breakthrough into a tangible shift in how the US plans to power its next generation of reactors.

More from Morning Overview