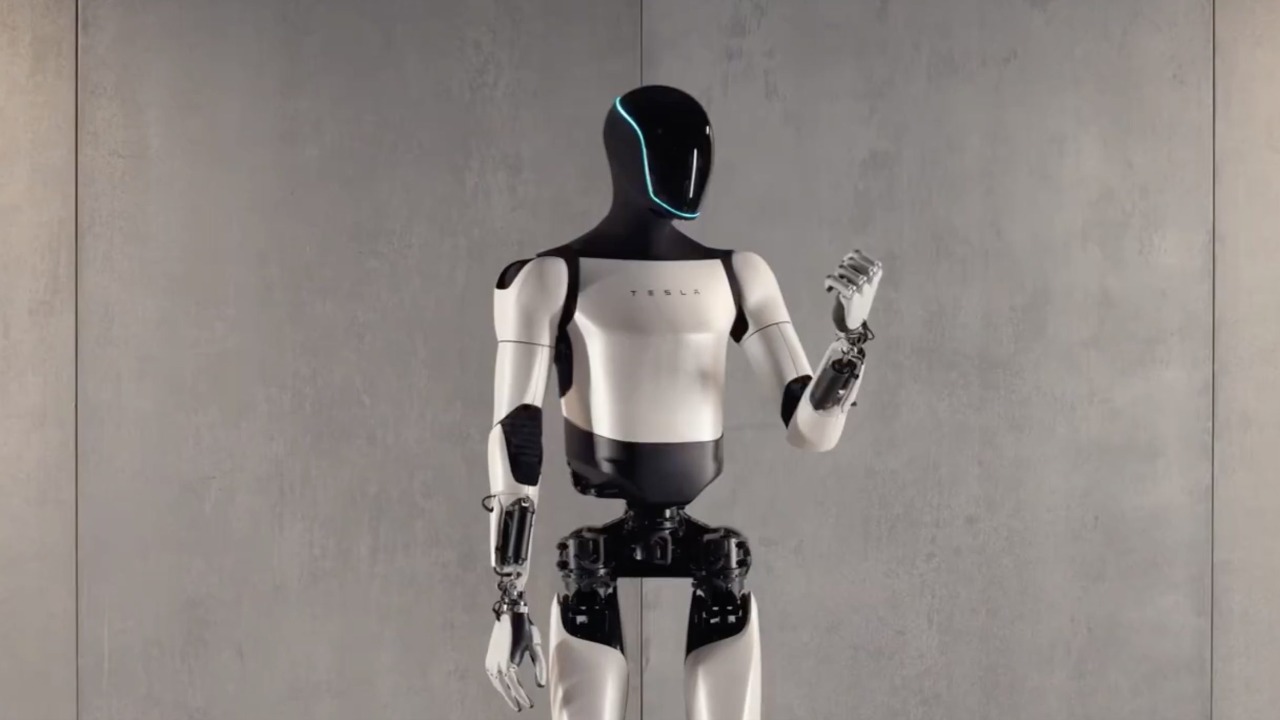

Tesla is preparing to turn its Austin manufacturing hub into a proving ground for its humanoid robots, positioning the Texas site as both a car plant and a training arena for Optimus. Internal briefings to staff suggest the company wants to capture human work on the factory floor and feed that data into an emerging robot workforce, raising fresh questions about how quickly automation could reshape industrial jobs.

The plan would deepen the strategic role of the Austin complex just as Tesla races to scale Optimus from flashy prototype to practical laborer. If the company succeeds, the same facility that helped define the electric vehicle boom could become the template for how robots learn to move, lift, and collaborate alongside people in high volume production.

The Austin factory as Optimus training ground

Tesla has told employees it intends to start collecting data at its Texas facility so Optimus can learn directly from human workers on the line. The idea is to embed the robot program inside the existing manufacturing flow at the Austin plant, rather than isolating it in a lab, so the machines are trained on the real motions, constraints, and safety rules that govern a live production environment. That approach would turn the factory into a kind of living classroom, where every repetitive task, from lifting parts to loading components, becomes a potential training clip for the robots.

According to internal discussions, Tesla framed the initiative as a way to teach Optimus to mimic the same movements that workers already perform in the plant, using the Texas site as a large scale data capture operation. The company has been developing Optimu in earlier phases, but the Austin plan signals a shift toward integrating the humanoids with the full complexity of a major facility. People familiar with the program have described the effort as a structured attempt to gather motion data across the factory, a step that aligns with Tesla’s broader push to use its Austin campus as a central node in its automation strategy.

Inside Tesla’s human-to-robot training pipeline

To translate human labor into robot behavior, Tesla is relying on a specialized group of Optimus trainers who effectively act as stand ins for the machines. These workers wear large helmets fitted with cameras that point in several directions, capturing their movements as they perform tasks on the line. The helmet system is designed to record not just what a person’s hands are doing, but also how they navigate the workspace, interact with tools, and respond to dynamic conditions around them, creating a rich dataset for the robot’s control software.

The company has described these Optimus trainers as a bridge between the current workforce and the future robot fleet, with the captured footage feeding into algorithms that will eventually guide the humanoids. In internal materials, Tesla has emphasized that the helmets and camera rigs are part of a broader effort to build a scalable training pipeline for Optimus, one that can be replicated across other plants once it is proven in Texas. The trainers’ gear, including the multi directional cameras and associated systems, is central to how Tesla expects to teach Optimus trainers to capture the data needed for the robots to eventually operate semi autonomously on the factory floor.

What Tesla told workers about the Optimus rollout

During a recent town hall event with employees, Tesla outlined its intention to begin gathering data for Optimus at the Austin facility, signaling that the project is moving from concept to implementation. People who were briefed on the plan said the company presented the training effort as a long term initiative, one that would start with limited data collection and gradually expand as the robots become more capable. The town hall format allowed managers to walk through how the humanoids might be introduced into specific workflows, and how human workers would initially supervise and correct their behavior.

In those discussions, Tesla indicated that the early focus would be on relatively contained tasks, such as moving parts or handling materials, before Optimus is trusted with more complex operations. The company also linked the Austin training push to its broader ambitions for the robot program, including potential deployment in logistics and other repetitive roles. People familiar with the event said that town hall, Tesla and TSLA leadership framed Optimus as a key part of the company’s future, while acknowledging that the robots will need extensive training before they can reliably share space with human colleagues.

From prototypes to a robot “army” in Texas

The Austin training plan sits alongside a much larger build out of Optimus infrastructure at the same site, including a dedicated facility within the Giga Texas campus. Earlier announcements described a stand alone building focused entirely on robot production, with a full capacity target set for 2027. That timeline underscores how quickly Tesla expects to move from a handful of prototypes to large scale manufacturing, using the Austin complex as both a training ground and a production base for its humanoid machines.

Company materials on the new facility have highlighted its role in consolidating Optimus development, from hardware assembly to software integration, under one roof. The stand alone structure is meant to plug directly into the broader Giga Texas ecosystem, drawing on the existing supply chains, engineering talent, and testing infrastructure already in place. In those plans, Tesla has described the Facility Specifications and for Giga Texas as a blueprint for how Optimus can be scaled to meet demand once the robots prove themselves on the factory floor.

Musk’s ambitions and the scale of the Optimus bet

Chief executive Elon Musk has repeatedly cast Optimus as a transformative project for Tesla, and the Austin training program fits squarely within that narrative. During Tesla earnings calls, he has described a future in which humanoid robots handle a significant share of physical labor, potentially reshaping the economics of manufacturing and logistics. Those comments have been paired with aggressive production targets, including references to a 10 million per year Optimus factory at Giga Texas, which would require an unprecedented ramp up in both hardware and training capacity.

In outlining these goals, Musk has pointed to an Optimus version 3 prototype as a key milestone, arguing that each new iteration brings the robot closer to practical deployment in real world jobs. Company materials describing these ambitions have emphasized that the Austin complex is central to this vision, serving as the launchpad for both training and mass production. In one summary of the project, Tesla highlighted how the CEO Elon Musk made During Tesla briefings hinge on turning Giga Texas into a hub where Optimus can be built, tested, and refined at scale.

More from Morning Overview