Electric vehicles have raced ahead on performance and price, but their batteries still struggle with durability, charging time, and raw material constraints. The most ambitious fix, solid-state chemistry, has long promised safer packs with more range in less space, only to be tripped up by cracking, dendrites, and short lifespans. Now a cluster of advances, from silver-infused solid electrolytes to sodium-based cells, suggests scientists may finally be closing in on the EV battery’s most stubborn weaknesses.

I see a pattern emerging across these projects: researchers are not chasing a single miracle material, they are methodically attacking the specific failure modes that make today’s packs heavy, slow to charge, and expensive. The result is a wave of breakthroughs that, taken together, could reshape how quickly EVs charge, how far they drive, and how long their batteries last before drivers ever notice degradation.

Why solid-state batteries keep breaking, and how silver changes the game

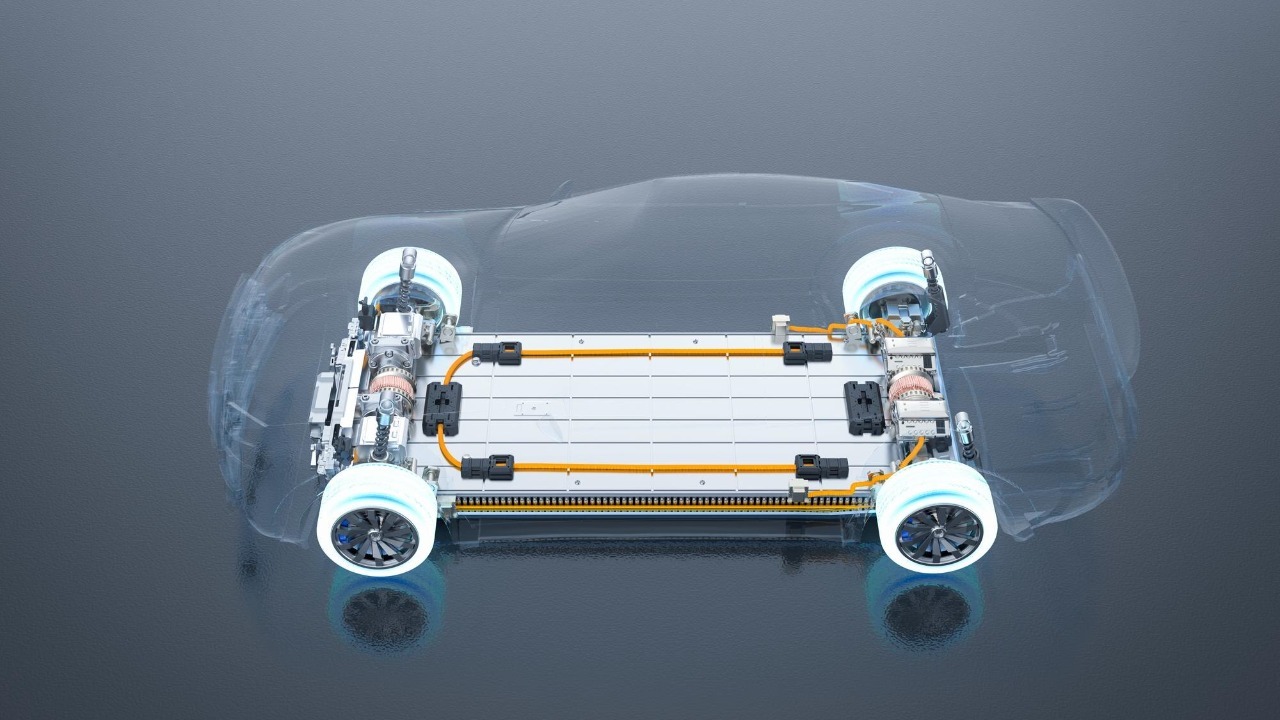

For years, engineers have treated solid-state batteries as the logical successor to today’s lithium-ion packs, since a solid electrolyte can, in principle, store more energy and tolerate faster charging without flammable liquid inside. The catch is that when lithium moves in and out of the electrodes, it can create stress that causes the solid layers to crack, which eventually makes the battery fail. Recent work highlighted by Solid shows that adding silver to the mix can relieve some of that mechanical stress, reducing the tendency for those deadly fractures to form in the first place.

In parallel, detailed modeling of how lithium filaments grow inside these cells has underscored why cracking is such a critical problem. Simulations of Li dendrites show that once tiny metallic protrusions start to form, they are followed by crack propagation, and that crack growth, in turn, accelerates the dendrites until they pierce the electrolyte. By using silver to tune the mechanical and electrochemical environment, the Jan team behind the Solid work is effectively trying to break that feedback loop, so the electrolyte stays intact even under aggressive cycling.

Using crystal chemistry to speed up lithium and stop failures

Silver is only one part of the story. Another group of scientists in South Korea has focused on the internal architecture of solid electrolytes, using what they describe as Using Crystal Chemistry to redesign how lithium ions move. By carefully arranging atoms in the solid electrolyte, they aim to Speed Up Lithium, which reduces the build up of local hotspots where dendrites and cracks tend to start.

Faster and more uniform ion transport is not just an academic goal, it directly addresses the biggest user-facing complaints about EVs: slow charging and capacity loss. If lithium can move quickly through a solid electrolyte without creating stress concentrations, packs can accept higher currents without overheating or degrading. That is why some battery engineers describe Solid electrolytes as a “holy grail” for EV energy density, provided these structural tweaks can be manufactured at scale.

From lab to road: Donut Lab, Donut Battery and the first solid-state EVs

Breakthroughs matter most when they leave the lab, and that is starting to happen. At CES, Estonian startup Donut Lab claimed it had effectively solved solid-state batteries and was preparing packs with a lifespan of 100,000 charge cycles for production vehicles. The company’s Estonian roots and presence at CES underline how quickly this field has shifted from big automakers to nimble specialists willing to bet their entire business on a new chemistry.

On the road, the first production cars using this technology are starting to appear under the Donut Battery banner, which is billed as the world’s first solid-state battery in production vehicles shipping to customers. A separate clip shared via Donut Battery shows the pack undergoing aggressive testing, a reminder that any solid-state breakthrough must survive not just lab cycles but potholes, fast-charging sessions, and years of daily use before it can claim to have fixed EVs’ durability problem.

Faster charging and longer life: lithium metal, SEI tweaks and thermal control

Even as solid-state designs mature, researchers are squeezing more performance out of lithium-metal cells that still use liquid electrolytes. A joint team in Korea has demonstrated a lithium-metal pack that can deliver 500 miles of range on a single charge, while also charging in about 12 minutes and lasting 186,411 miles before significant degradation. Another project described as an EV Battery Breakthrough reports 800 km of driving on a charge, with the authors saying this Range Lithium Metal has Ushered in a New Era for high energy density cells.

One reason these packs can survive such punishment is a microscopic coating called the solid electrolyte interphase. A separate study shared on social media explains how a tailored alloy forms a stable SEI, a protective layer that prevents runaway reactions and enables ultra fast charging over roughly 300,000 km of use. The same post, shared earlier as Sep, underscores how a seemingly small chemical tweak can unlock both faster charging and longer life, provided the interface between lithium and electrolyte stays intact.

Making today’s lithium-ion tougher while sodium and BYD reshape the market

While next generation chemistries grab headlines, incremental improvements to conventional lithium-ion cells are quietly extending EV lifespans. One line of research shows that high nickel cathodes can suffer when their crystal lattice distorts, creating oxygen holes that destabilize the structure and shorten battery life. By substituting a small amount of nickel with aluminum, researchers found they could suppress these oxygen holes, and follow up testing confirmed that this aluminum substitution significantly enhances the battery’s lifespan, as described in a separate aluminum report.

Automakers are already capitalizing on these kinds of gains. Chinese giant BYD says its 15 millionth new energy vehicle milestone reflects innovations in everything from battery chemistry and packaging to intelligent driving assistance, and it is preparing a new model destined for introduction in Europe in 2026. At the same time, a separate team at the KERI Energy Conversion Research in Korea has been working on thermal management so EVs keep performing optimally as packs age, rather than losing power and range as cells heat up.

More from Morning Overview