Heat-assisted magnetic recording is moving from lab curiosity to shipping product, and the payoff is simple: far more bits on every spinning disk. If current prototypes are any guide, the same 3.5‑inch form factor that tops out around 3 TB per platter today could realistically climb toward 10 TB per platter within a few product generations, reshaping how cloud providers, enterprises, and even power users think about hard drives.

Instead of chasing performance at any cost, the new wave of HAMR drives is about packing unprecedented capacity into familiar hardware while keeping power, cost, and reliability within the comfort zone of data center operators. I see that shift as the clearest sign yet that HDDs are not quietly fading behind SSDs, but evolving into a specialized, ultra‑dense cold and warm storage layer that will matter even more as AI and analytics workloads explode.

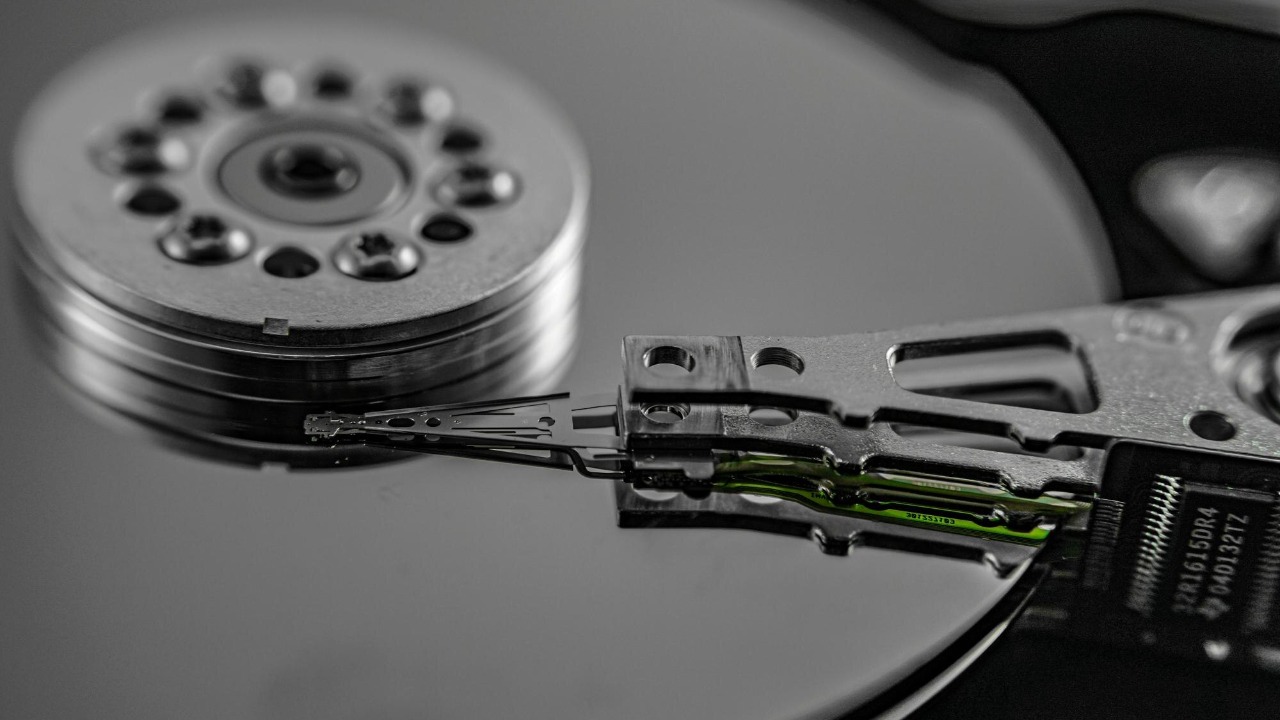

HAMR’s core idea: heat the media, shrink the bits

At its heart, HAMR is a materials science upgrade to a very mature technology. Traditional perpendicular magnetic recording is running into a wall because making bits smaller also makes them more vulnerable to stray magnetic fields, which limits how tightly they can be packed. HAMR sidesteps that limit by using a tiny laser to briefly heat a microscopic spot on the disk surface so it can be written at a much higher coercivity, then cools it almost instantly so the bit becomes extremely stable once set.

That combination of a near‑field laser, specialized media, and a conventional spinning platter lets engineers push areal density far beyond what classic PMR or even shingled recording can sustain. Seagate’s own technical overview of heat‑assisted recording describes how the write head integrates a nanophotonic transducer that focuses light into a sub‑wavelength hotspot, raising the temperature of the recording layer only in the region being written. The rest of the drive behaves like a familiar 3.5‑inch HDD, which is exactly why this approach is so attractive to hyperscale buyers who want capacity gains without a wholesale change in infrastructure.

From 6.9 TB per platter to a 10 TB horizon

The most concrete sign that HAMR is ready to stretch platter capacity comes from recent prototypes that already exceed anything in mass production. Seagate has demonstrated 3.5‑inch disks with 6.9 TB per platter, a figure that effectively doubles the areal density of many current enterprise drives. Reporting on these early units notes that a 55 TB hard drive can be built from eight of these 6.9 TB platters, which is a clear step beyond today’s 30 TB class products and a strong validation that the underlying media and heads can sustain such densities in a full‑stack design.

Those same 6.9 TB prototypes are described as a midpoint on a roadmap that targets even higher densities, not an endpoint. Coverage of the 6.9 TB per platter drives highlights that Seagate is already planning follow‑on generations with significantly tighter bit spacing, while separate analysis of HAMR density gains points to a path where a single 3.5‑inch platter could realistically approach 10 TB. If that trajectory holds, a standard eight‑platter stack would land around 80 TB, and higher‑stacked designs could push even further, all within the same basic mechanical envelope.

Why 10 TB per platter matters for data centers

For hyperscale operators, the jump from roughly 3 TB to something in the 7 to 10 TB range per platter is not just a nice round number, it is a direct lever on rack‑level economics. Every time capacity per drive doubles, a cloud provider can store the same dataset with half as many spindles, which cuts power draw, reduces the number of SATA or SAS ports, and simplifies maintenance. When I look at the 6.9 TB prototypes and the projected climb toward 10 TB, the most obvious impact is on total cost of ownership for exabyte‑scale cold storage clusters.

Analysts tracking next‑generation HAMR point out that these density gains arrive just as AI training, video archives, and compliance workloads are driving multi‑petabyte datasets into long‑term retention. At the same time, a feature deep dive into future 100 TB drives underscores how higher per‑platter capacity lets vendors build 3.5‑inch HDDs in the 80 TB to 100 TB class without exotic form factors. For operators who have already standardized on 4U, 60‑bay enclosures, that means they can scale from roughly 1.8 PB per chassis today to well over 5 PB in the same footprint once 10 TB per platter designs mature.

From 36 TB shipping drives to 55 TB prototypes

The leap toward 10 TB per platter is not happening in isolation, it is part of a broader rollout of HAMR into commercial products. Earlier this year, Seagate introduced 36 TB hard disk drives that use HAMR media and heads, marking the first time this technology has appeared in a capacity tier that large in a shipping product line. Coverage of those 36 TB drives notes that they are aimed squarely at cloud and enterprise customers who need dense, sequential throughput for object storage and backup workloads.

Financial reporting on Seagate’s roadmap adds that the company has publicly discussed a path from these 36 TB units to 40 TB and 50 TB models, with HAMR as the enabling technology for each step. In that context, the 55 TB prototypes built from 6.9 TB platters look less like a science project and more like the next rung on a ladder that is already in motion. A recent investor‑focused update on how Seagate unveils 36 TB hard drives ties those products directly to long‑term capacity targets, reinforcing the idea that per‑platter density will keep climbing as the company refines its media and head designs.

Engineering trade‑offs: lasers, reliability, and thermals

Integrating a laser into every write head is not a trivial change, and the move to HAMR forces drive designers to rethink reliability from the ground up. Each head now carries an optical path, a near‑field transducer, and additional power delivery, all of which must survive billions of write cycles in a harsh mechanical environment. That complexity raises obvious questions about long‑term durability, especially for data centers that expect drives to run 24/7 for five years or more.

Technical commentary on HAMR deployment notes that Seagate has spent years iterating on the media stack and head design to keep the heated region tightly confined and to prevent thermal stress from degrading the disk surface. At the same time, hands‑on coverage of 6.9 TB platter prototypes highlights that power consumption and operating temperatures remain within the envelope that existing data center racks can handle. From my perspective, that is the crucial point: if HAMR drives can deliver double the capacity without demanding exotic cooling or radically different failure models, operators are far more likely to adopt them quickly.

Performance characteristics in a HAMR world

One of the more subtle shifts with HAMR is how performance scales relative to capacity. Sequential throughput on a hard drive is largely a function of linear bit density and spindle speed, so when areal density doubles, sustained read and write rates climb as well. That means a 36 TB or 55 TB HAMR drive can stream data significantly faster than a 16 TB PMR unit, even if both spin at 7,200 rpm, which is a meaningful advantage for backup windows, media ingest, and AI training data staging.

However, random IOPS remain constrained by mechanical seek times, so the performance profile of HAMR drives still favors large, sequential workloads over small, latency‑sensitive transactions. A detailed look at next‑gen HDD performance emphasizes that these drives are not meant to replace NVMe SSDs for hot data, but to complement them as a deep storage tier. In that sense, the move toward 10 TB per platter is less about making hard drives “faster” in an absolute sense and more about ensuring that the cold and warm layers of the storage hierarchy can keep up with the explosive growth of primary data.

Roadmap to 80 TB, 100 TB, and beyond

When I trace the current HAMR milestones forward, the outline of the next decade of HDD capacity becomes clearer. With 36 TB HAMR drives already announced and 55 TB prototypes built from 6.9 TB platters in view, the next logical steps are 60 TB and 80 TB products that use higher per‑platter densities and possibly more platters per stack. Industry analysis of 100 TB class drives suggests that reaching triple‑digit capacities in a 3.5‑inch form factor will likely require per‑platter capacities in the 10 TB to 12 TB range, combined with advanced mechanical designs that can support ten or more disks in a single enclosure.

That roadmap aligns with the density projections tied to the current 6.9 TB media. Reporting on doubled areal density makes it clear that the underlying recording technology has headroom left, particularly as laser efficiency improves and media formulations are tuned for even higher coercivity. If vendors can maintain acceptable error rates and keep power per terabyte trending downward, I expect 80 TB drives to become a mainstream option for cloud storage within a few product cycles, with 100 TB units following as a premium tier for the largest archives.

What early adopters are learning from first‑gen HAMR

While the headline numbers are eye‑catching, the real test for HAMR is how it behaves in production. Early adopters in cloud and hyperscale environments are already running pilot deployments of 30 TB and 36 TB HAMR drives, using them in object storage clusters, backup repositories, and AI data lakes. Their feedback will shape how quickly the industry moves from cautious trials to broad rollouts, especially around firmware behavior, rebuild times, and failure patterns at these capacities.

Technical briefings and conference talks, including a detailed HAMR presentation that walks through field test data, indicate that first‑generation drives are meeting reliability targets comparable to mature PMR products. At the same time, coverage of prototype evaluations notes that operators are paying close attention to rebuild times, since reconstructing a 36 TB or 55 TB drive in a RAID or erasure‑coded pool can take significantly longer than for a 16 TB unit. That reality is pushing some architects toward designs that favor more parity, smaller fault domains, and smarter background scrubbing to keep risk in check as capacities climb.

How HAMR reshapes the HDD vs. SSD balance

The rise of HAMR also reframes the long‑running debate about when SSDs will “kill” hard drives. As NAND prices fall and QLC and PLC flash become more common, SSDs are clearly winning for hot data and latency‑sensitive workloads. Yet the ability to pack 80 TB or more into a single 3.5‑inch HDD at a lower cost per terabyte keeps spinning disks highly relevant for cold and warm tiers, especially when those tiers must scale into the multi‑exabyte range.

Analysts covering Seagate’s 36 TB launch frame HAMR as a way to extend the economic life of HDDs for at least another decade, giving cloud providers a clear reason to keep investing in disk‑based archives even as they expand their SSD fleets. A broader look at HAMR’s market impact echoes that view, arguing that the technology will help maintain a healthy price gap between HDD and SSD capacity. From my vantage point, the prospect of 10 TB per platter is less about saving hard drives from obsolescence and more about sharpening their role as the backbone of affordable, large‑scale storage in an AI‑driven world.

More from MorningOverview