China’s Geely has thrown down a gauntlet in the global EV race, unveiling a homegrown solid-state battery pack that hits an energy density of 400 Wh/kg and is slated for real-world vehicle testing in 2026. If the company can move this chemistry from engineering samples into mass production on that timeline, the leap in range, safety, and cost structure could reset expectations for electric cars worldwide.

I see this as more than a lab milestone. By pairing a 400 Wh/kg all-solid-state pack with a tightly controlled in-house supply chain and a growing portfolio of brands, Geely is positioning itself not just to catch established leaders, but to shape how and where the next generation of EV technology reaches the mass market.

Inside Geely’s 400 Wh/kg solid-state leap

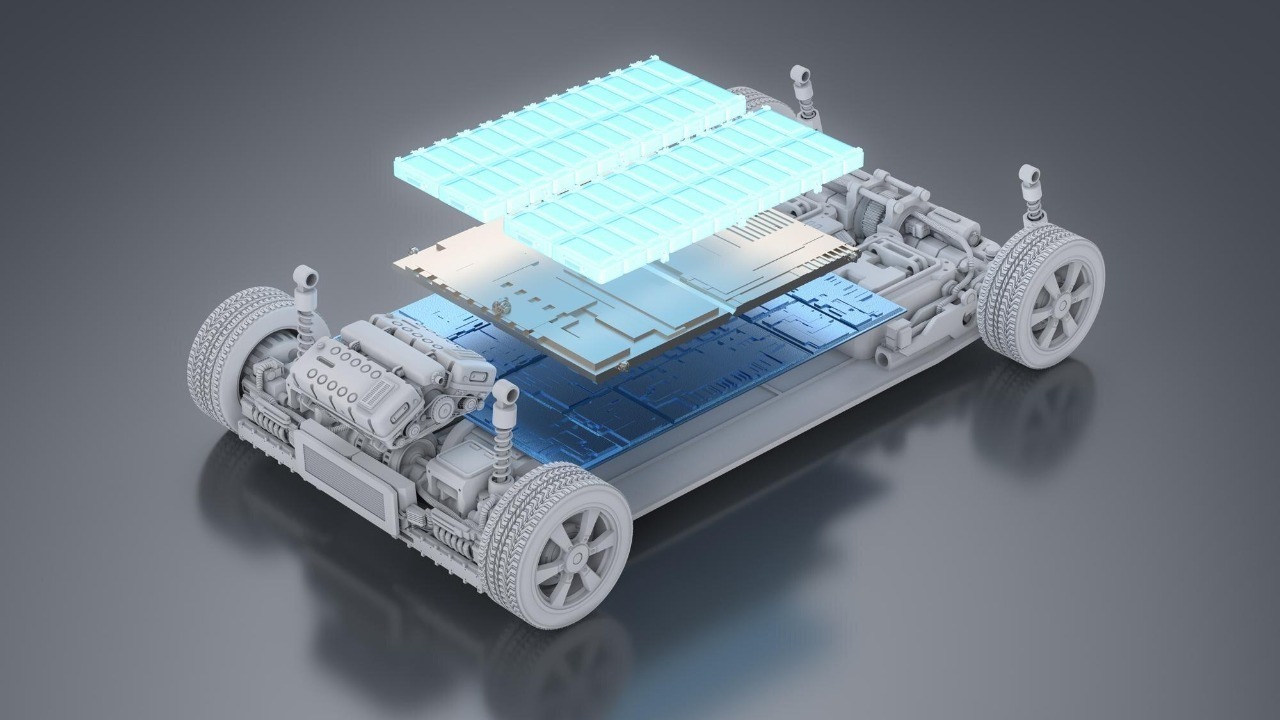

Geely’s announcement centers on a fully integrated all-solid-state battery pack that the company says reaches an energy density of 400 Wh/kg, a figure that would put it well ahead of today’s mainstream lithium-ion packs. Chinese carmaker Geely has framed this as an in-house breakthrough, with its own engineers developing the solid electrolyte, cell design, and pack integration rather than licensing an external platform. Reporting attributes the news to Bojan Stojkovski, underscoring how closely watched this development has become in industry circles.

The company is not just talking about cells on a bench. China’s Geely says its first fully integrated all-solid-state battery pack will be completed in 2026 and will undergo validation in real vehicles, a step that often reveals thermal, durability, and manufacturability issues that lab tests miss. According to According to company statements, the 2026 target covers both completion of the pack and validation under real operating conditions, which suggests Geely is confident enough in its materials stack to commit to a near-term road test schedule.

From lab samples to cars next year

The most striking part of Geely’s roadmap is how quickly it expects to move from engineering samples to vehicles. The company has confirmed a development milestone for its self-developed all-solid-state battery, stating that it has already produced 20 ampere-hour engineering samples and is preparing to scale those into full packs. That progress was highlighted by Geely as it laid out plans to begin vehicle testing in 2026, a timeline that would put solid-state hardware on public roads far sooner than many rivals had anticipated.

Video briefings on Geely’s Homegrown Solid State Battery Pack Hits 400 Wh/kg, Goes Cars Next Year Geely reinforce that the company intends to put this technology into production vehicles shortly after testing, with the phrase “Goes in Cars Next Year Geely” used to describe the planned rollout. One clip describes how Homegrown Solid State Battery Pack Hits 400 Wh/kg and explicitly notes that it Goes Cars Next Year Geely, signaling that the company is treating 2026 not as a distant research horizon but as the start of a commercial phase.

Why 400 Wh/kg matters for range, safety and cost

Energy density at 400 Wh/kg is not just a bragging right, it is a practical shift in what an EV can do on a single charge. At that level, a battery pack of the same weight as today’s typical units could deliver significantly more range, or automakers could hold range constant and shrink the pack to cut cost and improve efficiency. China’s China based Geely is pitching this as a way to challenge EV rivals that are still relying on conventional lithium-ion chemistries, and the numbers back up that ambition.

Solid-state batteries also promise gains in longevity and safety that matter as much as raw range. While conventional lithium-ion batteries typically begin to show noticeable degradation after approximately 5 to 8 years of use in electric vehicles, depending on usage and environmental factors, solid electrolytes are expected to reduce side reactions that eat into capacity over time. Research from UC Riverside notes that While conventional cells face these limits, solid-state designs can charge faster and last longer, which aligns with Geely’s emphasis on safety testing and durability for its new pack.

Geely’s in-house battery push and brand ecosystem

Geely is not approaching solid-state batteries as a side project, it is reorganizing its business around in-house energy storage. Company statements describe an in-house battery push with safety testing and a new LFP cell, and note that this consolidation allows Geely to bring battery, motor, and electronic control system development under one organization. That integrated strategy is detailed in a report on in-house development, which also highlights a multi-year, coordinated R&D strategy built around the solid-state program.

That matters because Geely is a big company with a wide stable of brands that can absorb and scale new technology. But Geely owns Lotus, Zeekr and Lynk & Co, in addition to Volvo, giving it multiple premium and mass-market channels for deployment. Analysts have pointed out that But Geely can use Lotus, Zeekr and Lynk and Volvo to bring solid-state technology to the mass market, rather than confining it to a single halo model, which could accelerate learning curves and cost reductions.

Challenging BYD, CATL and the wider EV field

Geely’s move lands in a Chinese market where competition is already intense, particularly with BYD and CATL. Commentators have described Geely as BYD’s biggest rival, noting that as J gets closer and closer to BYD in terms of sales on a monthly basis, the technology gap becomes the next battleground. A widely viewed breakdown of sales trends argues that Jan data shows BYD still ahead, but the gap is narrowing, and a credible 400 Wh/kg solid-state pack could give Geely a powerful differentiator in both domestic and export markets.

On the cell supplier side, CATL has been pushing its own high-range solutions, including a battery platform promoted as capable of 700 plus miles of range that aims to tackle range anxiety head-on. Analysts note that by addressing the critical issue of range anxiety, this innovation has the potential to accelerate the mass adoption of electric vehicles and that the long-term impact of this technology is undeniable. A recent overview of CATL’s 700 mile battery underscores how crowded the innovation race has become, which makes Geely’s decision to develop its own 400 Wh/kg solid-state pack rather than rely solely on external suppliers a strategic hedge.

More from Morning Overview