A groundbreaking catalyst has been unveiled by scientists, enabling the direct conversion of methane into bioactive compounds. This innovation could potentially revolutionize the way chemists synthesize materials for medical and industrial uses. It addresses the long-standing challenge of harnessing methane, the primary component of natural gas, which is abundant but notoriously difficult to transform without high energy inputs or wasteful byproducts. This breakthrough paves the way for more efficient production of bioactive materials, which could enhance drug development and sustainable manufacturing.

The Challenge of Methane in Chemical Synthesis

Methane, the primary component of natural gas, is abundant but has been underutilized due to its inherent difficulties in chemical synthesis. The strong carbon-hydrogen (C-H) bonds in methane typically require extreme temperatures or harsh conditions to activate in traditional methods. This has often led to low yields or environmental drawbacks, such as the production of wasteful byproducts.

The challenge has been to find a way to harness methane’s potential without these drawbacks. This has set the stage for the need for innovative catalysts that can activate methane under milder conditions and direct the reaction towards the production of useful compounds, such as bioactive materials.

Development of the Breakthrough Catalyst

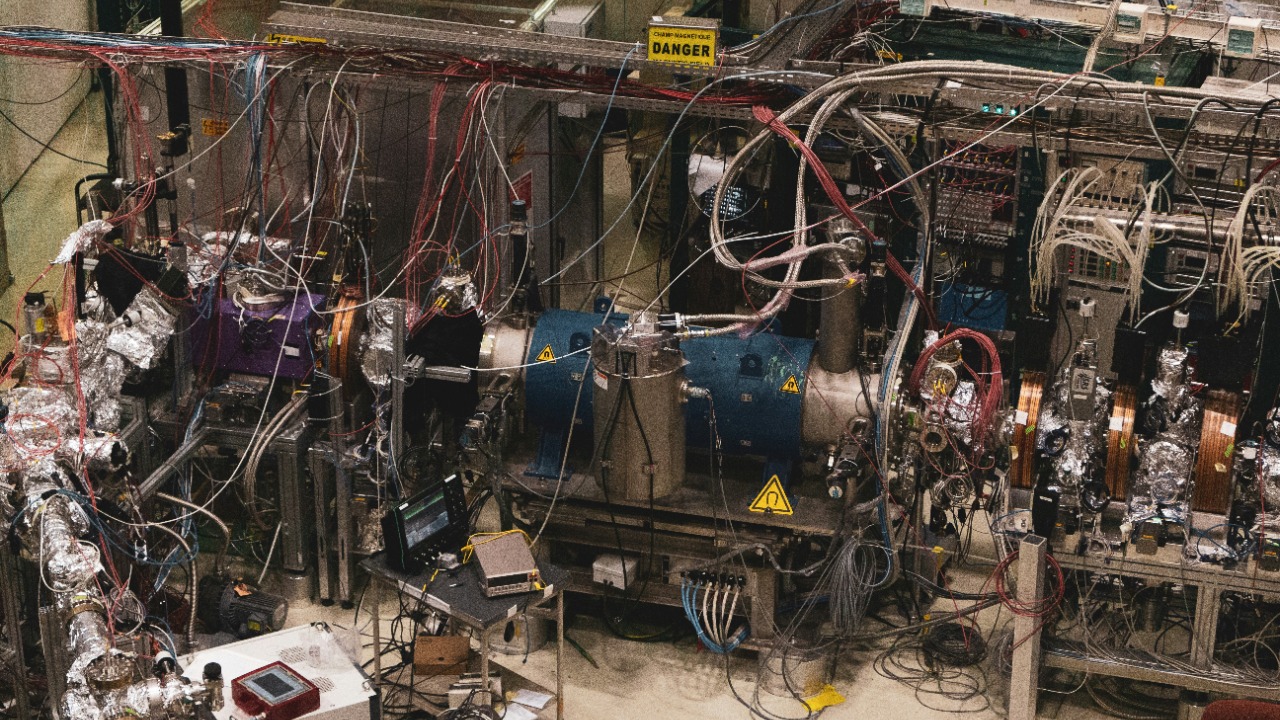

The development of this breakthrough catalyst is the result of interdisciplinary collaboration among chemists. The key design principles of the catalyst include incorporating metal centers to facilitate methane activation at milder conditions. This approach has proven successful in overcoming the challenges associated with methane conversion.

The announcement of the catalyst’s efficacy on November 14, 2025, marked a pivotal moment in the field of chemical synthesis. This breakthrough has the potential to revolutionize the way chemists synthesize materials for medical and industrial uses.

Mechanism of Methane Conversion

The mechanism of methane conversion involves a step-by-step process where the catalyst interacts with methane to form reactive intermediates. The catalyst selectively directs the reaction toward bioactive compound formation, avoiding the production of unwanted side products. This selectivity is a core achievement of the research, as it allows for the efficient conversion of methane into useful compounds.

Scientists have successfully used this catalyst to convert methane into bioactive compounds, a significant advancement in the field of chemical synthesis. This achievement opens up new possibilities for the efficient production of bioactive materials from methane.

Types of Bioactive Materials Produced

The catalyst enables the production of specific classes of bioactive compounds, including those with pharmaceutical potential. These compounds have structures that mimic natural biomolecules, making them suitable for targeted applications in medicine and other fields.

Initial lab tests have demonstrated improvements in yield and scalability, indicating the potential for this method to be used in large-scale production of bioactive materials. This is a promising development for industries that rely on these materials, such as the pharmaceutical industry.

Applications in Medicine and Beyond

The bioactive materials produced through this method could accelerate drug discovery by enabling direct synthesis from methane-derived precursors. This could potentially lead to the development of new and more effective treatments for various diseases.

Beyond medicine, these bioactive materials could also be used in industrial applications, such as creating biocompatible polymers for medical devices or sustainable fuels. This could reduce reliance on petrochemical feedstocks in bioactive production, contributing to more sustainable manufacturing practices.

Environmental and Economic Implications

The use of this catalyst in methane processing could have significant environmental benefits. By avoiding the production of wasteful byproducts and reducing the need for high energy inputs, this method could lower carbon emissions compared to conventional methane processing.

From an economic perspective, the catalyst could lead to cost benefits, including energy savings and access to cheaper raw materials like methane. This could have broader impacts on global energy markets and contribute to green chemistry initiatives, which aim to reduce the environmental impact of chemical processes.

Future Directions and Challenges

While this breakthrough is promising, there are still challenges to be addressed. One of these is scaling the catalyst for commercial production while maintaining efficiency. Ongoing research is needed to optimize the catalyst for diverse methane sources and integrate it with renewable energy sources.

Despite these challenges, the potential for further innovations building on this breakthrough is immense. It could lead to the development of more versatile bioactive materials, expanding their potential applications in medicine and other fields. This is an exciting prospect for the future of chemical synthesis and its role in sustainable manufacturing and drug development.

More from MorningOverview