Active Fuel Management (AFM), a cylinder deactivation technology introduced by General Motors, allows engines like the one in the 2011 Chevrolet Silverado to deactivate four cylinders during light-load conditions to improve fuel efficiency by up to 20%. However, this system has been linked to lifter noise issues in affected vehicles, where the lifters fail to properly collapse or extend, leading to audible ticking or tapping sounds. These problems have prompted numerous owner complaints and service bulletins for GM trucks and SUVs equipped with AFM (MotorTrend) (Jalopnik).

What Is Active Fuel Management?

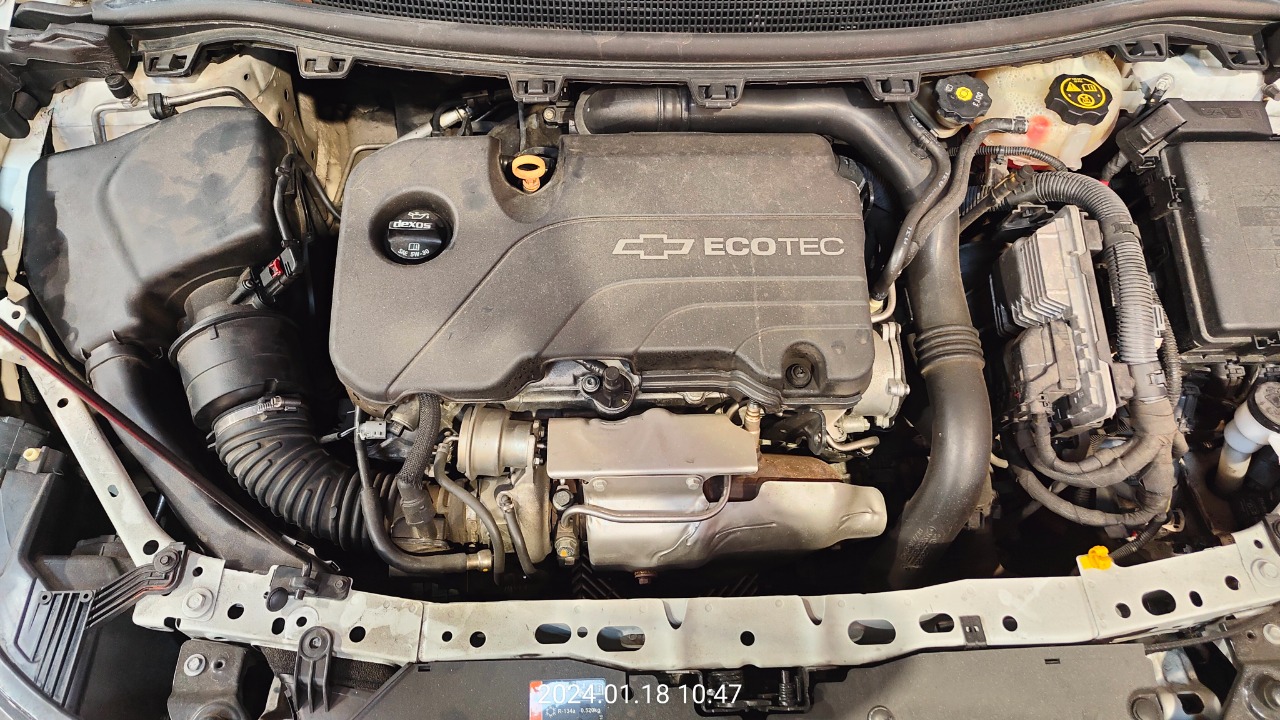

Active Fuel Management (AFM) is a GM-specific engine technology designed to dynamically deactivate cylinders to optimize fuel economy without sacrificing performance. First implemented in V8 engines starting in the mid-2000s, AFM aims to enhance fuel efficiency by shutting down half of the cylinders in a V8 during cruising or low-demand scenarios. This process reduces fuel consumption while maintaining seamless operation for the driver, ensuring that performance remains unaffected during transitions (Jalopnik).

AFM has been integrated into popular GM models, such as the 2011 Chevrolet Silverado, where it contributes to EPA-estimated improvements in highway mileage. By deactivating cylinders when full power is not needed, AFM allows these vehicles to achieve better fuel economy, which is particularly beneficial for long-distance highway driving. This technology has become a staple in GM’s lineup, reflecting the company’s commitment to balancing performance with environmental considerations (MotorTrend).

How Does AFM Operate in Modern Engines?

The mechanical process behind AFM involves the use of special lifters and solenoids controlled by the engine computer to lock out intake and exhaust valves on selected cylinders, effectively turning a V8 into a V4. This transformation is achieved through the precise control of oil pressure, which deactivates the lifters to prevent valve movement in idle cylinders. The system is designed to engage seamlessly, ensuring that drivers do not notice the transition between active and deactivated cylinders (Jalopnik).

For instance, in the 2011 Chevrolet Silverado, AFM engages above 40 mph under steady throttle conditions. This allows the vehicle to switch modes without driver input, optimizing fuel efficiency during highway cruising. The technology’s ability to operate without noticeable disruption is a key selling point, as it provides the benefits of improved fuel economy without compromising the driving experience (MotorTrend).

Common Causes of Lifter Noise in AFM Systems

Despite its advantages, AFM systems are not without their issues, particularly concerning lifter noise. AFM lifters, which are designed to collapse under oil pressure, can stick or fail due to varnish buildup or inadequate lubrication. This can result in noisy operation during mode transitions, as the lifters struggle to properly collapse or extend. Such issues are often exacerbated in high-mileage engines, where wear and tear can lead to more frequent problems (Jalopnik).

Another common issue is wear on AFM components like the Lifter Oil Manifold Assembly (LOMA), which routes oil to the lifters and is prone to clogging. This can lead to insufficient oil flow, causing the lifters to malfunction and produce a persistent ticking noise. Owners of vehicles like the 2011 Chevrolet Silverado have reported such issues, often misdiagnosed as general engine knock but directly tied to AFM engagement (MotorTrend).

Addressing and Mitigating AFM-Related Lifter Issues

Diagnosing AFM-related lifter noise involves several steps, including using a scan tool to monitor AFM solenoid activation and listening for noise patterns that correlate with cylinder deactivation. Identifying the exact cause of the noise is crucial for effective repair, as it allows technicians to target the specific components that are malfunctioning (MotorTrend).

Repair options for AFM-related issues include replacing faulty lifters or the entire LOMA unit, which can be a costly endeavor, with expenses ranging from $1,000 to $2,000 for GM vehicles like the 2011 Chevrolet Silverado. Preventive measures, such as regular oil changes with AFM-compatible synthetic oils, can help reduce deposits and prolong the life of AFM components. Additionally, aftermarket disable kits are available to prevent cylinder deactivation altogether, eliminating the risk of noise but also sacrificing the fuel efficiency benefits of AFM (Jalopnik).

Broader Implications of AFM for Vehicle Owners

While AFM offers significant fuel efficiency improvements, boosting models like the 2011 Chevrolet Silverado by 5–7 mpg, it also introduces reliability concerns that can affect resale value and owner satisfaction. The trade-offs between efficiency and potential mechanical issues are a critical consideration for prospective buyers, who must weigh the benefits of improved mileage against the risk of costly repairs (MotorTrend).

In response to these challenges, GM has issued technical service bulletins for AFM noise in post-2011 models and extended warranties for lifter failures, demonstrating a commitment to addressing customer concerns. However, some owners may still prefer alternatives, such as opting for non-AFM engine variants or considering competitors’ technologies like Ford’s variable displacement, which have fewer reported noise complaints (Jalopnik).