For the first time, scientists have watched metal crystals take shape inside a pool of molten metal, capturing a process that usually unfolds out of sight in the heart of furnaces and casting lines. By combining liquid metals with high-speed X-ray imaging, researchers have turned a hidden industrial workhorse into something visible, measurable and, unexpectedly, beautiful.

The result is not just striking footage but a new way to probe how metals solidify, crack and ultimately fail, with implications for everything from jet engines to flexible electronics. I see this as a rare moment when a fundamental physics experiment doubles as a practical tool for cleaner manufacturing and more resilient technology.

Peering into a hidden world of liquid metal

Metal crystals are the microscopic building blocks that determine whether a turbine blade survives years of stress or a smartphone circuit fails after a few drops. Until now, most of what engineers knew about how those crystals form inside molten metal came from theory, computer models and post-mortem analysis of solid pieces. The new work changes that by letting researchers watch individual crystals nucleate and grow in real time inside a liquid metal bath, turning a once abstract process into something directly observable.

Researchers achieved this by pairing a pool of liquid metal with an intense X-ray beam, then recording how the beam scattered as crystals emerged and expanded. That approach, described in detail in an analysis of how scientists can now watch metal crystals grow inside liquid metal, reveals the evolving internal structure without disturbing the sample. Instead of inferring what happened after the metal cooled, scientists can now track the exact moment a crystal appears, how quickly it spreads and how neighboring crystals compete for space.

The X-ray breakthrough that made the footage possible

At the heart of this advance is a refined X-ray imaging technique that trades static snapshots for high-speed movies. By tuning the energy of the beam and synchronizing it with fast detectors, the team could capture successive frames of the same region inside the molten metal, effectively filming the birth and evolution of crystals. I find this particularly powerful because it bridges the gap between atomic-scale simulations and the millimeter-scale features that matter in real components.

Reports on the experiment describe how the X-ray setup was optimized to track subtle changes in density and orientation as crystals formed, a capability highlighted in coverage of the X-ray technique that captures footage of crystals in action. The same work is presented as a landmark by the university team that led it, which emphasized that the method can be tuned for different alloys and cooling rates, as detailed in their announcement that scientists had captured footage of crystals growing inside liquid metal. That flexibility is crucial if the technique is to move from a one-off demonstration to a standard tool in metallurgy labs.

What the crystal movies reveal about how metals really solidify

Seeing crystals grow inside a liquid metal bath immediately challenges some of the simplifying assumptions that have guided metal casting for decades. Instead of a smooth, uniform front of solidification, the footage shows a dynamic landscape of competing crystals, branching structures and sudden shifts in growth direction. I read this as a reminder that even in a controlled furnace, metals behave more like living systems than static materials, with local fluctuations shaping the final structure.

Detailed commentary on the experiments notes that the movies reveal how small variations in temperature and composition can cause certain crystals to dominate while others stall, a behavior that helps explain why nominally identical castings can end up with very different microstructures. That insight is echoed in broader coverage that describes how scientists can now watch metal crystals as they form, rather than relying solely on averaged measurements. By correlating specific growth patterns with later defects, engineers can start to design casting conditions that favor strong, uniform grains and suppress the seeds of cracks.

From mesmerizing visuals to industrial impact

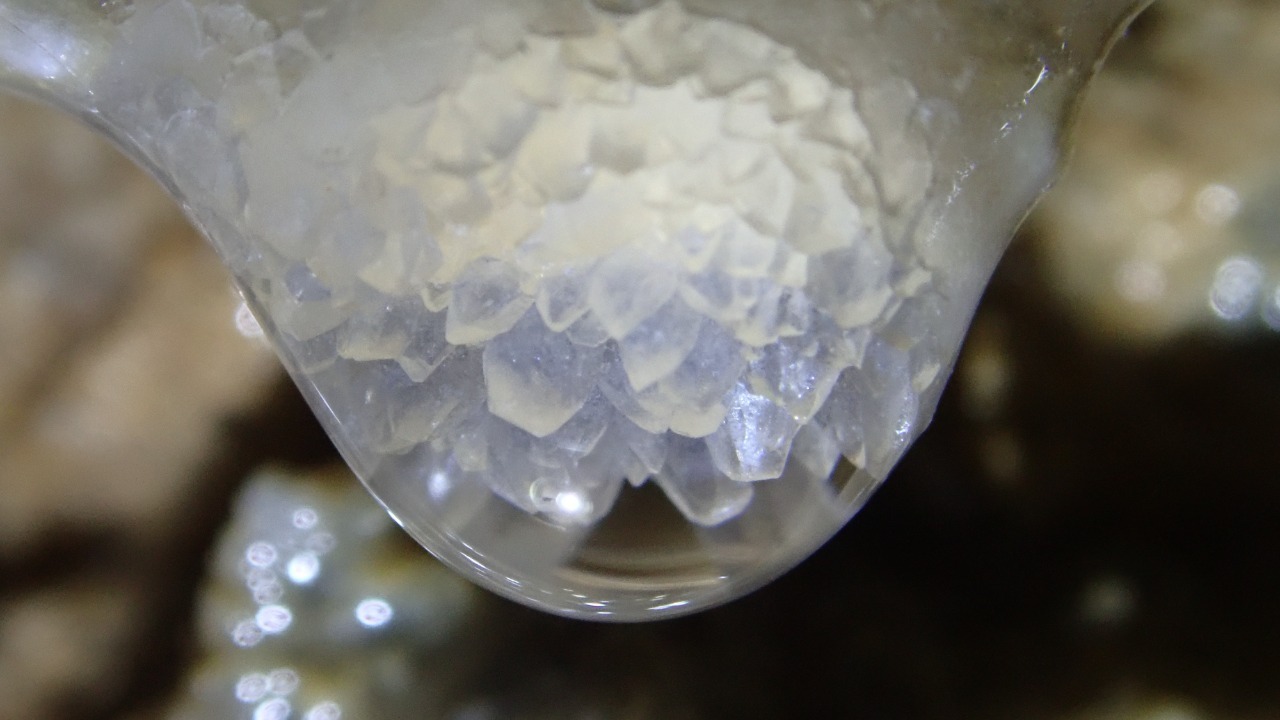

The footage of crystals blooming inside molten metal is visually arresting, and researchers have leaned into that by releasing clips that look more like abstract art than industrial diagnostics. In one widely shared video, branching structures radiate outward as the liquid cools, creating a time-lapse of solidification that is both scientifically rich and surprisingly cinematic. I see value in that aesthetic appeal, because it draws in viewers who might never otherwise think about how the metals in their cars or laptops are born.

Those visuals are not just for show. They are already being used to refine models of solidification and to test how tweaks in alloy composition or cooling rate change the resulting crystal network. A detailed release on how X-ray imaging captures crystal growth in metals underscores that the same technique can be applied to industrial alloys used in aerospace and energy. By matching the filmed patterns to mechanical tests, manufacturers can start to predict which casting recipes will yield parts that last longer under stress, potentially cutting waste and improving safety.

Why crystal growth matters for everyday technologies

It is easy to treat crystal growth as an esoteric topic, but the way metals solidify touches almost every technology that relies on strength, conductivity or flexibility. Turbine blades in jet engines, for example, are often engineered to have large, aligned crystals that resist creep at high temperatures, while the copper traces in a smartphone benefit from fine, uniform grains that carry current efficiently. Being able to watch those grains form in real time gives engineers a new lever to tune performance at the microscopic level before a single part is machined.

Earlier work on visualizing metal crystals, including time-lapse photography of solidifying alloys, hinted at this connection by revealing the intricate patterns that emerge as metals cool. A detailed feature on time-lapse photos of metal crystals highlighted how subtle changes in conditions can produce dramatically different structures, from dendritic trees to mosaic-like grains. The new X-ray movies extend that idea into three dimensions and into the interior of molten samples, where the most consequential transformations occur, giving designers a more faithful picture of how processing choices ripple through to real-world performance.

Seeing crystals with the naked eye and the rise of “time crystals”

The ability to watch crystals grow inside liquid metal sits alongside a broader trend of making once-invisible structures visible, sometimes even to the naked eye. In a separate line of research, physicists have reported creating a so-called time crystal that can be directly observed without specialized detectors, a milestone that blurs the line between abstract quantum phases and tangible objects. I find it striking that both efforts, though very different in scale and physics, share a common goal: turning hidden order into something we can literally see.

Coverage of the first time crystal visible to the human eye describes how a carefully engineered system can exhibit repeating patterns in time rather than space, a behavior that challenges conventional notions of equilibrium. Follow-up reporting on the same experiment, including an analysis of how a time crystal becomes visible under the right conditions, underscores how advances in imaging and control are making exotic states of matter more accessible. While time crystals and metal solidification live in different corners of physics, both benefit from tools that convert abstract dynamics into watchable phenomena.

Public engagement through video and lab storytelling

One of the most effective ways researchers have shared these breakthroughs is through short, tightly edited videos that walk viewers through the experiments. In the case of metal crystal growth, lab teams have released explanatory clips that pair animations with real footage, helping non-specialists connect the shimmering patterns on screen with the underlying physics of nucleation and growth. I see this as part of a broader shift in how materials science is communicated, with visual storytelling taking a central role.

Educational channels and institutional accounts have amplified that approach by hosting explainers on platforms where audiences already seek out science content. A representative example is a video that breaks down how X-ray imaging can reveal hidden structures in metals, similar in style and intent to a lab-produced explainer on crystal growth in materials. Other clips focus on the broader theme of phase transitions and pattern formation, echoing the same visual language used in demonstrations of crystal formation experiments that have attracted large audiences. By weaving the new liquid metal footage into that ecosystem, scientists are turning a niche imaging advance into a gateway for public curiosity about how the material world is built.

More from MorningOverview