Researchers have made a significant breakthrough in the field of gas purification with the development of a new type of crystal. This innovation could potentially lead to cleaner and more affordable industrial processes, addressing long-standing challenges in separating gases like methane from contaminants. The crystals, reported in October 2025, represent a step forward in materials science for energy efficiency.

The Need for Advanced Gas Purification

Current methods for gas purification, particularly in industries such as natural gas processing, are plagued by inefficiencies. These include high energy use and the generation of chemical waste, both of which contribute to environmental degradation and increased operational costs. The need for innovation in this field is driven by both environmental and economic pressures, including stringent regulations on emissions and the rising costs of traditional adsorbents like zeolites. source

These challenges have real-world impacts. For instance, contamination in biogas production can lead to lower purity levels, affecting the quality and efficiency of the end product. The development of these new crystals could therefore have significant implications for industries reliant on gas purification processes.

Development of the New Crystals

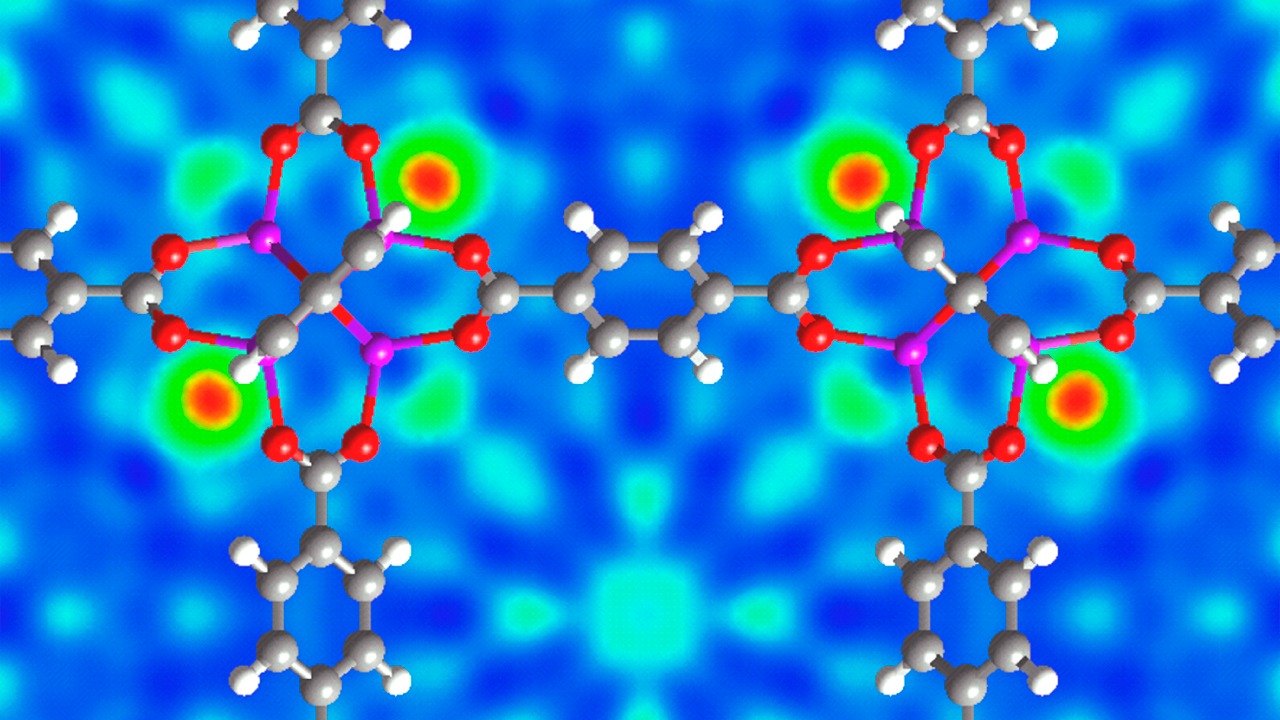

The research process behind these new crystals, known as metal-organic framework (MOF) crystals, focused on their tunable pore structures for selective gas adsorption. This was achieved through the use of organic linkers and metal nodes, resulting in a high surface area. The research was conducted by teams specializing in porous materials at a leading university lab, highlighting the collaborative and interdisciplinary nature of this innovation. source

Mechanism of Gas Separation

The MOF crystals work by selectively adsorbing impurities like carbon dioxide or hydrogen sulfide from methane streams. This is achieved through a process of size-exclusion and chemical affinity, which allows the crystals to target specific contaminants. Compared to conventional technologies, the crystals require lower pressure and have faster regeneration cycles, making them more efficient and cost-effective. source

Initial data on the crystals’ adsorption capacities have been promising, with specific metrics for gas uptake under standard conditions showing significant improvements over traditional methods. This suggests that the crystals could be a viable alternative for gas purification in a range of industrial applications.

Environmental Benefits

The use of these new crystals could lead to significant environmental benefits. For one, they could reduce the use of chemical solvents in purification plants, leading to less wastewater and hazardous waste. Additionally, the crystals could decrease greenhouse gas emissions from energy-intensive processes, contributing to efforts to mitigate climate change. source

There are also potential applications in carbon capture, a process that is crucial for achieving global sustainability goals. By improving the efficiency and affordability of carbon capture, these crystals could play a key role in the transition to a more sustainable energy infrastructure.

Economic Advantages

From an economic perspective, the crystals offer several advantages. They are reusable, which means they require fewer replacements and lower energy for operation, leading to cost savings. Furthermore, initial figures suggest potential reductions in purification expenses per unit of gas, with percentages lower than current methods. source

There are also considerations around scalability for industrial adoption. While there may be an initial investment required to implement the use of these crystals, the long-term returns in sectors like oil and gas could be substantial. This makes the crystals an attractive option for industries looking to improve their environmental footprint while also reducing costs.

Challenges and Next Steps

Despite the promising potential of these crystals, there are still challenges to overcome. For instance, the stability of the crystals under high-pressure industrial conditions needs to be further tested. There is also the need for large-scale manufacturing processes to be developed to meet potential demand. source

Looking ahead, the next phases of research will include pilot testing, with timelines set for post-October 2025. Industry experts will also need to consider commercialization barriers and regulatory approvals. Despite these challenges, the potential benefits of these crystals make them a promising area of research in the quest for cleaner and more efficient energy production.

Broader Implications for Energy

The implications of this research extend beyond natural gas purification. The crystals could also be used in hydrogen production or air separation for clean energy technologies, potentially leading to significant shifts in the global energy market. Projections for adoption in regions like North America and Europe suggest that these crystals could play a key role in the transition to sustainable energy infrastructures. source

As one of the lead scientists on the project noted, the development of these crystals represents a significant step forward in materials science for energy efficiency. By addressing long-standing challenges in gas purification, these crystals could pave the way for cleaner and more affordable industrial processes, contributing to global sustainability efforts.