Researchers at Stanford University have made a significant breakthrough in the fight against climate change by developing a new catalyst that efficiently converts carbon dioxide (CO2), a potent greenhouse gas, into methanol. This versatile energy carrier and chemical feedstock could potentially transform industrial emissions into valuable products. The innovation, which achieves over 90% selectivity for methanol production under mild conditions, could be directly integrated into power plant chimneys, reducing atmospheric CO2 while generating cleaner fuels.

The Catalyst’s Design and Mechanism

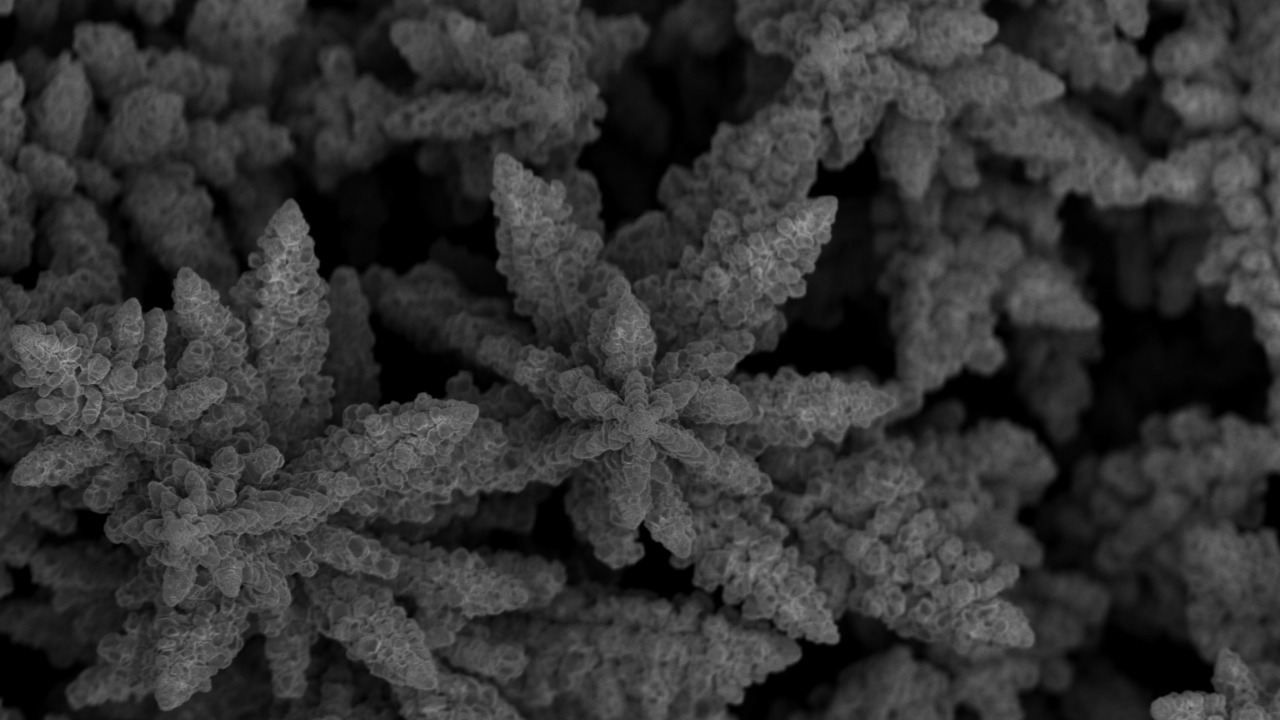

The catalyst, a product of Stanford’s Department of Chemical Engineering, is composed of copper nanoparticles embedded in a nitrogen-doped carbon matrix. This unique design enhances CO2 adsorption and stabilizes reaction intermediates for selective reduction to methanol, addressing key challenges in carbon capture and utilization [source]. Unlike traditional catalysts that favor carbon monoxide production, this catalyst operates at atmospheric pressure and temperatures below 200°C, minimizing energy input while achieving a Faradaic efficiency of 92%.

Lead researcher, Professor Thomas Jaramillo, explained the bio-inspired approach behind the catalyst. “This catalyst mimics natural enzymes but with industrial scalability in mind,” he said, highlighting the potential for large-scale implementation [source].

Experimental Validation and Performance Metrics

In lab tests using simulated flue gas from coal-fired power plants, the catalyst processed CO2 concentrations up to 15%—typical of industrial emissions—yielding 150 grams of methanol per kilogram of catalyst per hour [source]. Durability tests showed the catalyst maintaining 85% efficiency after 100 hours of continuous operation, outperforming previous copper-based systems that degrade due to sintering [source].

Electrochemical measurements confirmed a low overpotential of 0.3 volts, making it compatible with renewable electricity sources like solar or wind for sustainable operation [source].

Applications in Carbon Capture and Fuel Production

The technology targets integration into existing smokestacks at facilities like the Stanford-led test site in California. Here, it could capture and convert 1 ton of CO2 daily into 0.6 tons of methanol, which could be used in transportation fuels [source]. The methanol produced serves as a hydrogen carrier for fuel cells or as a precursor for plastics, potentially offsetting 20% of global methanol demand from fossil sources by 2030 if scaled [source].

Collaborators from the U.S. Department of Energy’s Joint Center for Artificial Photosynthesis noted, “This advances our goal of a carbon-neutral economy,” emphasizing partnerships for pilot-scale deployment [source].

Challenges and Future Scaling Efforts

Despite the promising results, there are still challenges to overcome. The catalyst is sensitive to impurities like sulfur dioxide in real flue gas, requiring pre-treatment filters that add 10-15% to operational costs [source]. Scaling to industrial levels involves optimizing electrode fabrication for larger electrolyzers, with Stanford planning a demonstration unit at a 50-megawatt power plant by 2027 [source].

Economic analysis projects a methanol production cost of $450 per ton, competitive with natural gas-derived methods, but dependent on carbon credits to reach full viability [source]. Despite these challenges, the potential of this catalyst to transform greenhouse gas emissions into valuable products represents a significant step towards a more sustainable future.