Artificial intelligence has just helped push one of the world’s most familiar metals into unfamiliar territory. By teaming advanced algorithms with 3D printing, researchers have created a new aluminum alloy that is about five times stronger than the material used in traditional cast parts, yet still light enough for aircraft and electric cars. The result is not a lab curiosity but a printable metal that performs on par with the strongest aluminum alloys made through conventional techniques, opening a path to lighter, tougher hardware across multiple industries.

Instead of tweaking recipes by trial and error, the team used AI to search through vast combinations of elements and microstructures, then validated the winning design in real-world printers and stress tests. The work shows how machine learning can compress years of metallurgical experimentation into a rapid design loop, turning aluminum, already a backbone of modern engineering, into something closer to a programmable material platform.

How AI and 3D printing reinvented aluminum

The core breakthrough is not just a tougher metal, it is a new way of discovering metals in the first place. Researchers at the Massachusetts Institute of Technology used artificial intelligence to design a printable aluminum alloy whose strength reaches levels far beyond conventional aluminum, then proved that the material could actually be manufactured with standard metal printers. Instead of relying on incremental tweaks to known alloys, they let algorithms explore how different elements and processing conditions might combine to create a microstructure that resists deformation and cracking at extreme loads, and only then translated that digital design into a physical powder.

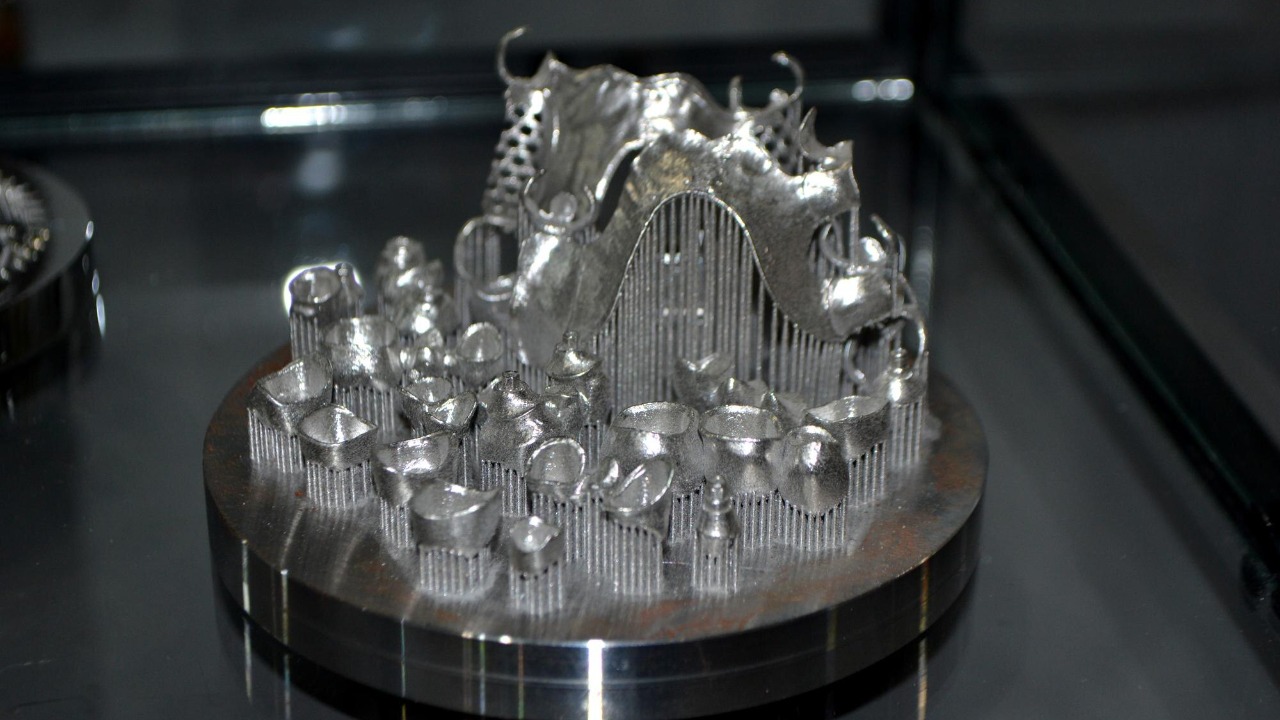

Once the AI had identified a promising composition, the team ordered a batch of printable metal powder and used it to fabricate test pieces that could be compared directly with traditional cast parts. According to their reported results, the printed metal performed on par with the strongest aluminum alloys currently produced through traditional casting, confirming that the computational design was not just a simulation artifact but a real material with record strength. The researchers described how they had just engineered a printable alloy that pushes aluminum to strength levels far beyond conventional aluminum, a claim backed by Testing Confirms Record Strength.

Inside the alloy: aluminum plus five carefully chosen elements

At the heart of the advance is a powder that looks unremarkable but encodes a complex design. The base is aluminum, prized for its low density and corrosion resistance, but the AI system recommended adding five other elements in precise proportions to create a stable, ultra-fine microstructure. This mix was not chosen for marketing appeal, it was selected because the model predicted that, once melted and rapidly solidified in a 3D printer, it would form nanoscale features that block dislocations, the tiny defects that normally let metals bend and eventually fail.

To test that prediction, the team did not rely on in-house equipment alone. They sent the powder, described explicitly as a mix of aluminum and five other elements, to collaborators in Germany who printed small samples using commercial additive manufacturing systems. Those printed parts were then characterized in detail, including at MIT.nano’s characterization facilities, to see whether the real microstructure matched the AI’s expectations and whether the strength gains held up under mechanical testing. The description of how They sent the powder to Germany and confirmed the resulting structure and performance is laid out in Printable aluminum alloy.

From simulation to stress test: proving the “5x stronger” claim

Claims about strength are easy to make and hard to prove, which is why the mechanical testing campaign around this alloy matters as much as the AI design work. After the powder was printed into standardized specimens, the researchers subjected them to tensile tests that pulled the metal until it fractured, measuring how much stress it could withstand compared with conventional cast aluminum. The results showed that the new alloy is about five times stronger than its cast counterpart, a dramatic jump that moves it into the same performance bracket as high-end aerospace aluminum while keeping the weight advantage that makes aluminum so attractive in the first place.

Equally important, the tests indicated that the printed samples were not just strong but also resistant to the brittleness that can plague ultra-hard materials. Reports on the work note that tests on printed samples confirmed that the new alloy is not only five times stronger than its cast counterpart but also maintains useful ductility, meaning it can absorb energy without shattering. That combination of strength and toughness is what allows engineers to design thinner, lighter parts without sacrificing safety margins, a point underscored in coverage of how Tests validated the AI-guided design.

MIT’s additive manufacturing push and why it matters

The project sits within a broader push at MIT to rethink metals for Additive Manufacturing rather than simply feeding old alloys into new printers. Engineers from the Massachusetts Institute of Technology have been explicit that many legacy aluminum grades were optimized for casting or forging, not for the rapid melting and solidification cycles inside a laser powder bed machine. By designing an alloy specifically for those conditions, they aim to unlock parts that are both lighter and stronger, instead of forcing compromises that come from using materials outside their comfort zone.

Reports on the work describe how MIT develops 5x stronger aluminium alloy for Additive Manufacturing, highlighting that Engineers at the Massachusetts Institute of are targeting applications where every gram saved translates into fuel savings or longer battery life. The emphasis on additive processes is not incidental, it is central to the strategy, because 3D printing allows intricate internal lattices and cooling channels that are impossible to cast, and a stronger alloy lets those delicate structures survive real-world loads. The institutional focus on this combination of material and process is captured in coverage of how MIT develops 5x stronger aluminium alloy for next generation printers.

AI as a co-designer: using machine learning to pick the winning recipe

What sets this alloy apart from earlier high-performance aluminums is the way it was conceived. Instead of manually exploring a handful of compositions, the team used machine learning to scan a vast design space of potential mixtures and processing conditions, then narrowed in on candidates that balanced strength, printability, and resistance to high temperature degradation. In effect, AI acted as a co-designer, proposing recipes that human metallurgists might not have considered, while still relying on expert judgment to filter out combinations that would be too expensive or impractical to manufacture at scale.

Accounts of the project describe how MIT engineers have just redefined what aluminum can do by Using 3D printing combined with machine learning to create a new alloy that pushes performance boundaries. The breakthrough offers a glimpse of how future materials development could look, with algorithms rapidly identifying the optimal mix of elements and heat treatments for a given application, then handing that blueprint to additive manufacturing systems that can realize it in metal. That vision is captured in descriptions of how Using 3D printing combined with machine learning allowed the Massachusetts Institute of Technology team to move from concept to printed parts far faster than traditional methods.

Record strength and high temperature resilience

Strength at room temperature is only part of the story for any structural alloy that might end up in an aircraft wing or an electric vehicle chassis. The researchers therefore pushed the new aluminum mix through tests at elevated temperatures to see whether its microstructure would coarsen and lose strength, a common failure mode for lightweight metals. Their results confirmed the predictions from the AI models, showing that the alloy maintains unusually high strength even when heated to levels that would soften many standard aluminum grades, which is critical for components exposed to engine heat or aggressive braking cycles.

Detailed reporting notes that their results confirmed the predictions about how the alloy’s nanoscale features would remain stable at high temperature for aluminum alloys, supporting the idea that this is not just a cold-weather material but a candidate for demanding aerospace and automotive environments. That combination of record strength and thermal resilience is what allows commentators to talk about a printable aluminum alloy that sets strength records and may enable lighter aircraft parts, a claim grounded in the description that Their results confirmed the predictions about high temperature performance.

From lab to flight deck: lighter aircraft and beyond

The most immediate beneficiaries of a fivefold strength boost in aluminum are likely to be aerospace manufacturers, who have spent decades shaving grams from airframes and engine components. With a printable alloy that matches the strongest cast aluminum while enabling more intricate geometries, designers can imagine brackets, ribs, and housings that are both thinner and more efficient, potentially cutting fuel burn or extending range. The fact that the material is tailored for additive manufacturing also means that low-volume, highly customized parts, such as those in business jets or experimental aircraft, can be produced without the tooling costs that come with casting or forging.

Coverage of the work emphasizes that the printable aluminum alloy sets strength records and may enable lighter aircraft parts, a phrase that captures both the performance leap and the application focus. Because the alloy is compatible with existing metal 3D printers, aerospace suppliers that already use additive manufacturing for titanium or nickel components could, in principle, add this aluminum powder to their portfolio and start experimenting with lighter alternatives where corrosion resistance and weight are more important than extreme heat tolerance. The prospect of such deployment is grounded in the description of how MIT Engineers Create 3D-Printable Aluminum 5 Times Stronger Than Conventional Alloys with Lightweight Strength for Extrem conditions in mind.

Why “printable” strength changes industrial design

Beyond aerospace, the significance of this alloy lies in how it changes the design rules for any product that can benefit from both low weight and high strength. In automotive engineering, for example, a 5x strength increase could allow thinner crash structures or battery enclosures that free up space and reduce mass, which is especially valuable in electric vehicles where every kilogram affects range. Consumer electronics makers could imagine laptop frames or drone arms that are slimmer yet more resistant to bending, while industrial robotics companies might use the material to build lighter arms that move faster without sacrificing stiffness.

What makes these scenarios plausible is that the alloy is not a theoretical construct but a 3D-printable material that has already been produced and tested using standard manufacturing techniques. Reports stress that MIT researchers have designed a printable aluminum alloy that can be made using standard manufacturing techniques, which means companies do not need exotic new equipment to start exploring its potential. That compatibility with existing printers and post-processing lines is highlighted in descriptions of how MIT researchers have designed the alloy to slot into current industrial workflows rather than demand a complete retooling.

A new playbook for materials discovery

Stepping back, the story of this alloy is also a story about how AI is rewriting the playbook for materials science. Traditional alloy development can take a decade or more, as researchers cycle through composition tweaks, casting trials, and mechanical tests, often guided as much by intuition as by data. By contrast, the MIT work shows how machine learning models, trained on existing metallurgical knowledge, can propose candidate recipes that are far more likely to succeed, allowing experimentalists to focus their time and budget on the most promising options and iterate quickly when results come back from the lab.

In that sense, the 5x stronger aluminum is both a product and a proof of concept. It demonstrates that AI can do more than optimize ad targeting or language translation, it can help reshape the physical materials that underpin transportation, energy, and infrastructure. The description of how Dec reports framed the achievement, noting that MIT Engineers Create 3D-Printable Aluminum 5 Times Stronger Than Conventional Alloys and that the work delivers Lightweight Strength for Extrem environments, underscores that this is not a marginal improvement but a step change in what engineers can expect from aluminum. That framing is captured in the way MIT, Engineers Create a bridge between AI-driven design and real-world manufacturing.

More from MorningOverview