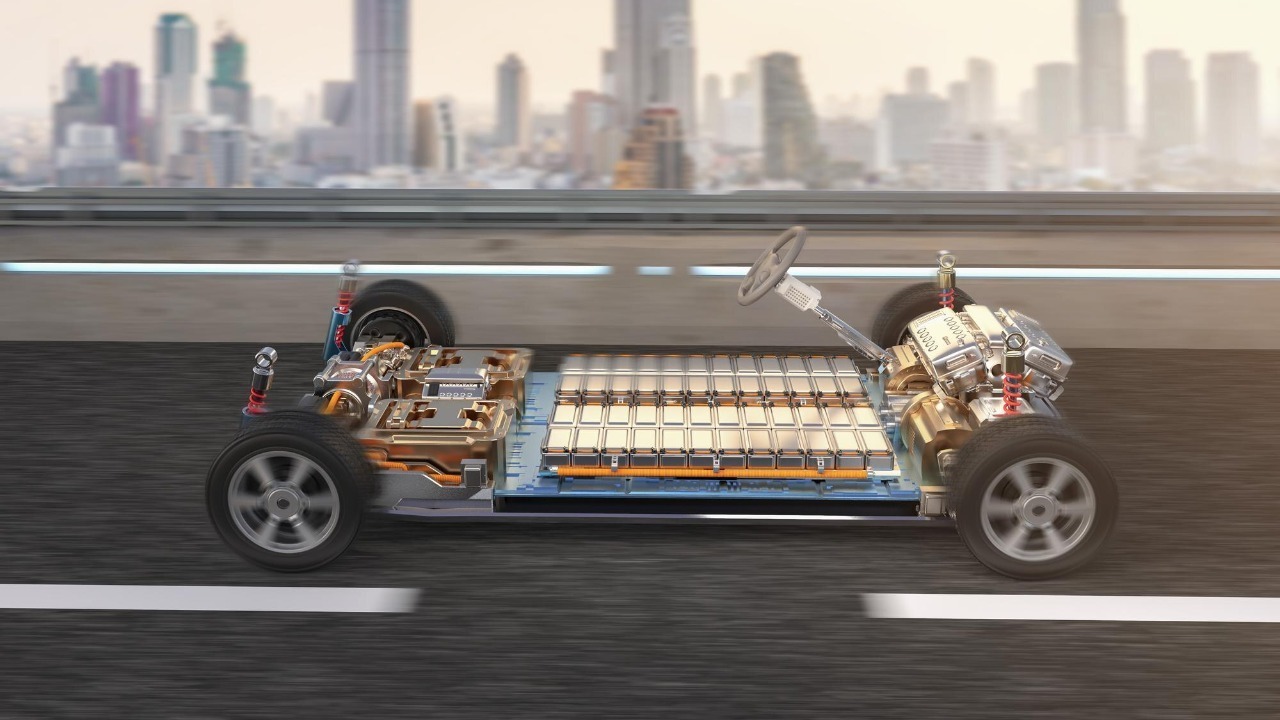

Electric vehicles are supposed to be the low‑maintenance workhorses of the energy transition, yet a growing trail of recalls, sudden breakdowns, and alarming lab data suggests something inside their packs is quietly going wrong. Instead of predictable, gradual wear, many failures trace back to flaws that were effectively baked into the battery long before the car left the factory. A hidden defect, often microscopic and invisible to routine checks, is emerging as a common thread linking safety scares, warranty headaches, and shaken consumer confidence.

What looks like a random failure in a driveway in Arizona or a taxi depot in Europe increasingly points back to the same place: the production line. Researchers, safety agencies, and independent repair shops are converging on a picture in which tiny particles, stray bits of metal, and subtle structural irregularities inside cells can trigger internal shorts, thermal runaway, or early capacity loss. The stakes are not just technical, they are economic and political, because the credibility of mass electrification depends on packs that last as long as promised.

The quiet shift from wear‑and‑tear to manufacturing fault

For years, the dominant story about electric car batteries was simple: they slowly lose capacity as drivers fast‑charge, floor the accelerator, and rack up mileage. That narrative is now being complicated by evidence that a significant share of failures are not the result of hard use but of defects that were present from day one. A comprehensive review of defects in Lithium cells describes how seemingly minor irregularities introduced during production can later manifest as internal shorts, gas generation, or sudden loss of capacity, reframing many breakdowns as quality control failures rather than owner abuse.

That distinction matters because it changes who is on the hook. If a pack fails because a driver fast‑charged aggressively in extreme heat, the blame is easy to shift. If it fails because a microscopic metal shard pierced a separator, the responsibility sits squarely with the manufacturer and its suppliers. The same review notes that there are many types of flaws, from misaligned electrodes to contamination, but it singles out manufacturing defects worldwide as a leading safety concern, which helps explain why automakers are increasingly facing recalls and warranty claims tied to the factory rather than the road.

Inside the cell: how tiny particles become big problems

At the heart of this story is the cell itself, a tightly wound sandwich of electrodes and separator that has to be manufactured with almost surgical cleanliness. When that standard slips, particle contamination can creep in, and what looks like harmless dust can become a future failure point. Technical guidance on Particle contamination explains that stray material inside cells can puncture separators, create localized hotspots, and severely impact battery performance, turning a single defect into a chain reaction that degrades an entire pack.

Researchers are also uncovering more subtle flaws that are not just about dirt in the wrong place. Work involving Princeton Engineering, Vanderbilt, and Argonne and Oak Ridge National Labs has highlighted how irregularities in the crystalline structure of solid electrolytes can create stress points and microcracks that evolve into internal shorts. These are not the kind of defects that show up in a quick voltage test at the end of the line, which is why they can remain hidden until a pack has been in service for years.

Metal foreign matter: the defect researchers fear most

Among the many things that can go wrong inside a cell, metal foreign matter stands out as particularly dangerous. A detailed Abstract on Lithium battery safety identifies metal particles as a primary culprit behind manufacturing‑related failures, because even a tiny conductive fragment can bridge electrodes and trigger an internal short. Once that happens, the cell can heat rapidly, vent, or in the worst case enter thermal runaway, which then threatens neighboring cells and the entire pack.

Another technical summary framed through Sep reporting reinforces that this is not a theoretical edge case but a recurring pattern across factories and chemistries. The comprehensive review it describes identifies metal foreign matters as a primary culprit behind manufacturing‑related battery failures and argues that detecting and eliminating these particles is one of the most effective ways to prevent failures before they occur. That conclusion is pushing cell makers to invest in more sensitive inspection systems and cleaner production environments, but it also underscores how much risk is still riding on the invisible quality of each batch.

Dirty air in clean rooms: the factory‑level weak link

Even the best cell designs are only as reliable as the air and surfaces in the plants that build them. Reports on The Hidden Danger Inside EV Battery Plants describe how dust and airborne particles in electrode coating and assembly areas can embed themselves in cells, setting the stage for overheating and costly product recalls. The same analysis notes that poor dust control does not just threaten safety, it also slows down production and increases costs, because lines must be stopped and reworked when contamination is detected.

Another section on The Risk of Thermal Runaway and Air Contamination explains that during critical steps such as electrode drying and cell formation, even small amounts of airborne metal or conductive dust can create conditions for internal shorts. During these stages, cells are particularly vulnerable because materials are still settling and interfaces are forming, so a single contaminant can become a permanent defect. The result is a paradox: factories that look spotless to the naked eye can still be seeding future failures if their filtration and air handling systems are not tuned to the microscopic scale that Lithium cells demand.

Recalls expose how hidden defects reach the road

When these microscopic problems escape the factory, they eventually show up as very visible recalls. Guidance for drivers on what sparks an EV battery recall notes that Manufacturers have been forced to repair or replace packs when internal defects create fire risks or sudden loss of power, even in relatively new vehicles. Since February 2020, General Motors has had to address issues in Chevrolet Bolt packs, and other brands have followed with their own campaigns as they discover that small fractions of cells in certain production windows are prone to failure.

The pattern is visible in more recent cases too. In one high profile example, Tesla Recalls Nearly 13,000 Vehicles As Battery Pack Defect Could Cause Loss Of Drive after identifying a problem with a pack contactor supplied from Taiwan, a reminder that even components adjacent to the cells can introduce hidden vulnerabilities. A separate safety notice recorded that a Battery pack contactor may fail, causing a loss of drive power, which the US traffic safety agency linked to a connection failure in around the same number of cars. In both cases, the defect was not something a driver could see or influence, yet it directly affected whether the vehicle could safely stay on the road.

Independent clinics and “extremely high” failure rates

While official recalls capture the most serious safety issues, independent repair shops are often the first to spot patterns in everyday failures. According to a report that cites What is happening inside some popular packs, the EV Clinic has warned about unusually high failure rates in certain Tesla models that use LG cells. According to According to that analysis, these LG cells perform worse than expected and often cannot be economically repaired at the cell level once they start to fail, which suggests that underlying design or manufacturing choices are limiting their real‑world lifespan.

Similar concerns are being raised about imported packs. A separate investigation notes that Researchers have sounded the alarm on Chinese EV batteries after studying them in real‑world practice and finding what they described as Extremely high failure rates even when the packs were relatively new. The EV Clinic stated that some of these batteries degraded or failed far earlier than owners expected, again pointing to hidden flaws rather than simple age or mileage as the root cause.

Not all bad news: data that busts degradation myths

Against this backdrop of defects and recalls, it is easy to assume that all EV batteries are fragile. Large scale field data tells a more nuanced story. A New study of 1,300 EVs, highlighted by Fred Lambert, found that packs from Kia and Tesla topped the list for low degradation, challenging the idea that most EV batteries will quickly become unusable. The same dataset reported that average capacity loss was far lower than many early skeptics predicted, suggesting that when cells are built correctly, they can easily outlast typical ownership cycles.

That contrast is important because it shows that the industry’s problem is not inherent to Lithium chemistry but to variability in manufacturing and quality control. The study’s findings, which were summarized at Oct 41, indicate that when packs avoid the kinds of hidden defects described in lab reviews, their performance over time is remarkably stable. In other words, the worst failures are not representative of the entire fleet, but they are severe enough to demand attention because they can undermine public trust in the technology as a whole.

Why battery management cannot fully mask bad cells

Automakers often point to sophisticated software as a safety net, arguing that smart battery management systems can detect and isolate problems before they become dangerous. There is some truth to that, but engineers are increasingly candid about the limits of software when the underlying hardware is flawed. A technical discussion framed as Battery Management vs. Pack Failure explains that More dangerous are failure mechanisms that create internal shorts or disconnects inside a cell, because these can develop faster than monitoring systems can react.

In particular, the thread highlights Lithium Plating and other internal degradation modes that can be accelerated by manufacturing defects. When plating builds up on anode surfaces, it can form dendrites that pierce separators, a process that is often invisible to pack‑level sensors until it is too late. Software can limit charging rates or flag abnormal voltages, but it cannot heal a separator that was weakened by a metal particle or a misaligned electrode years earlier. That reality reinforces the central lesson emerging from the research: the most effective way to prevent catastrophic failures is to stop hidden defects from entering the pack in the first place.

Where the industry goes from here

As I weigh the evidence from lab studies, factory reports, recalls, and field data, a clear pattern emerges. The most troubling EV battery failures are not random acts of chemistry but the delayed consequences of small mistakes in design and manufacturing. Reviews of Jun and How Air Contamination is Slowing Down Production and Increasing Costs show that the industry knows where many of the weak points are, from particle control to metal foreign matter, yet the pressure to scale up quickly keeps those risks in play. The challenge now is to treat microscopic quality as a strategic priority, not an afterthought, because the cost of getting it wrong shows up years later in the form of stranded vehicles and shaken consumer trust.

There are reasons for cautious optimism. The same research that exposes hidden flaws also points to better inspection methods, cleaner plant designs, and more robust cell architectures that can tolerate small imperfections without failing catastrophically. As more data accumulates from fleets and independent clinics, I expect regulators and buyers to demand clearer disclosure about failure rates and defect modes, and for automakers to compete not just on range and price but on the invisible reliability of their packs. If that happens, the hidden defect behind today’s failures could become the catalyst for a quieter, more durable generation of EV batteries that finally lives up to the promise written into every warranty.

More from MorningOverview