Turning methane into ethylene with sunlight sounds like alchemy, but it is rapidly moving into the realm of practical chemistry. A new generation of solar-driven catalysts promises to convert a potent greenhouse gas into one of industry’s most important building blocks while using far less energy than today’s fossil-fueled processes.

Instead of burning methane or letting it leak into the atmosphere, researchers are learning how to upgrade it directly into higher-value molecules under mild conditions. If these systems scale, they could cut emissions at oil fields and landfills, reshape the economics of ethylene production, and give chemical makers a cleaner route to plastics and fuels.

Why methane and ethylene are the critical pieces of this story

Methane sits at the center of the climate problem because it traps far more heat than carbon dioxide over a 20‑year period, yet it is still routinely flared or vented from wells, pipelines, and waste sites. At the same time, ethylene is one of the most heavily produced chemicals on Earth, a feedstock for polyethylene packaging, PVC pipes, synthetic rubber, and a long list of solvents and intermediates that underpin modern manufacturing. Linking these two molecules, by turning unwanted methane into ethylene, directly targets a major source of warming while feeding a massive industrial demand.

Today, most ethylene comes from steam cracking, a process that heats hydrocarbons like naphtha or ethane to extremely high temperatures, often above 800 degrees Celsius, and consumes large amounts of fossil energy. Researchers working on sunlight-powered catalysts argue that if methane can be upgraded to ethylene at or near room temperature, the energy savings could be dramatic and the carbon footprint of ethylene production could fall sharply. That is the context in which a new solar catalyst that converts methane to ethylene with far less energy has drawn so much attention.

A sunlight-powered catalyst that upgrades methane directly

Recent work on solar-driven catalysis has shown that it is possible to activate methane using photons instead of the intense heat and pressure of conventional reactors. In these systems, a solid catalyst absorbs sunlight and uses that energy to break the strong carbon–hydrogen bonds in methane, guiding the fragments toward more complex molecules rather than simple combustion. One reported design focuses specifically on steering the reaction toward ethylene, so that the greenhouse gas becomes a feedstock instead of a waste stream, and it does so under relatively mild conditions compared with traditional petrochemical plants, according to a description of a sunlight methane breakthrough.

Researchers involved in this line of work describe a system in which methane molecules interact with a photocatalyst that has been engineered to favor carbon–carbon coupling over complete oxidation. By tuning the surface structure and electronic properties of the material, they report that they can raise the selectivity toward ethylene and other valuable products while limiting the formation of carbon dioxide. The same reporting notes that the process is driven by solar energy rather than by burning additional fuel, which is why it is being framed as a cleaner pathway to ethylene production that could, in principle, be deployed at sites where methane is currently wasted.

Inside the University of Queensland’s solar conversion breakthrough

One of the most detailed accounts of this approach comes from a team that describes a sunlight-powered system designed to turn methane into ethylene and related chemicals using a tailored catalyst. In their reporting, the researchers explain that they built a reactor that operates under ambient conditions and uses concentrated light to excite a catalyst surface, which then promotes the coupling of methane molecules into higher hydrocarbons. They emphasize that the process targets ethylene as a primary product, positioning it as a way to turn a problematic gas into a valuable commodity, and they present it as a sunlight-powered breakthrough rather than an incremental tweak to existing petrochemical routes.

According to the same account, the team highlights that their catalyst design improves both the efficiency and the selectivity of the reaction compared with earlier photocatalytic attempts. They point to the potential for integrating such reactors at methane-rich sites, including gas fields and waste facilities, where the gas is currently flared or vented. By capturing that methane and feeding it into a solar-driven reactor, they argue, operators could generate ethylene on-site and either use it locally or feed it into existing chemical supply chains, all while reducing the climate impact of their operations.

From waste methane to essential chemical feedstock

The appeal of these solar catalysts is not just that they use less energy, but that they can turn what is currently treated as waste into a core industrial input. Reporting on one such system describes how methane that would otherwise be burned off at oil and gas facilities can be captured and fed into a reactor that produces ethylene directly, framing the process as a way to convert methane waste into an essential chemical. The same coverage stresses that ethylene is central to plastics, textiles, and a wide range of industrial products, which is why a sunlight catalyst converts methane waste narrative resonates with both climate advocates and manufacturers.

In that account, the researchers underscore that their approach avoids the intermediate step of turning methane into synthesis gas, a mixture of hydrogen and carbon monoxide that is often used as a bridge to more complex molecules. By skipping that stage and going straight from methane to ethylene, they argue that they can reduce both capital costs and energy losses. They also note that the process can be tuned to favor different products depending on the catalyst composition and operating conditions, but they single out ethylene because of its outsized role in global chemical markets and its potential to anchor new, lower-carbon value chains at the point of methane capture.

How the solar catalyst actually works at the surface level

At the heart of these advances is a class of photocatalysts that absorb sunlight and use the resulting charge carriers to drive chemical reactions on their surfaces. In the case of methane upgrading, the catalyst must perform a delicate balancing act: it needs to activate the very stable methane molecule without over-oxidizing it to carbon dioxide. One description of a new system explains that the catalyst architecture is designed to create active sites that favor the formation of carbon–carbon bonds, which is the key step in building ethylene from methane fragments, and that this design is central to the solar-powered catalyst turns methane into ethylene claim.

According to that reporting, the catalyst is illuminated so that electrons and holes are generated within the material, and these charge carriers then participate in the activation of methane at the surface. The researchers describe how they control the reaction environment, including temperature and gas composition, to steer the process toward partial oxidation and coupling rather than complete combustion. They also highlight that the catalyst remains stable over multiple cycles, which is crucial for any industrial application, and that the use of sunlight as the primary energy input is what allows the system to operate with significantly lower external energy demand than conventional ethylene plants.

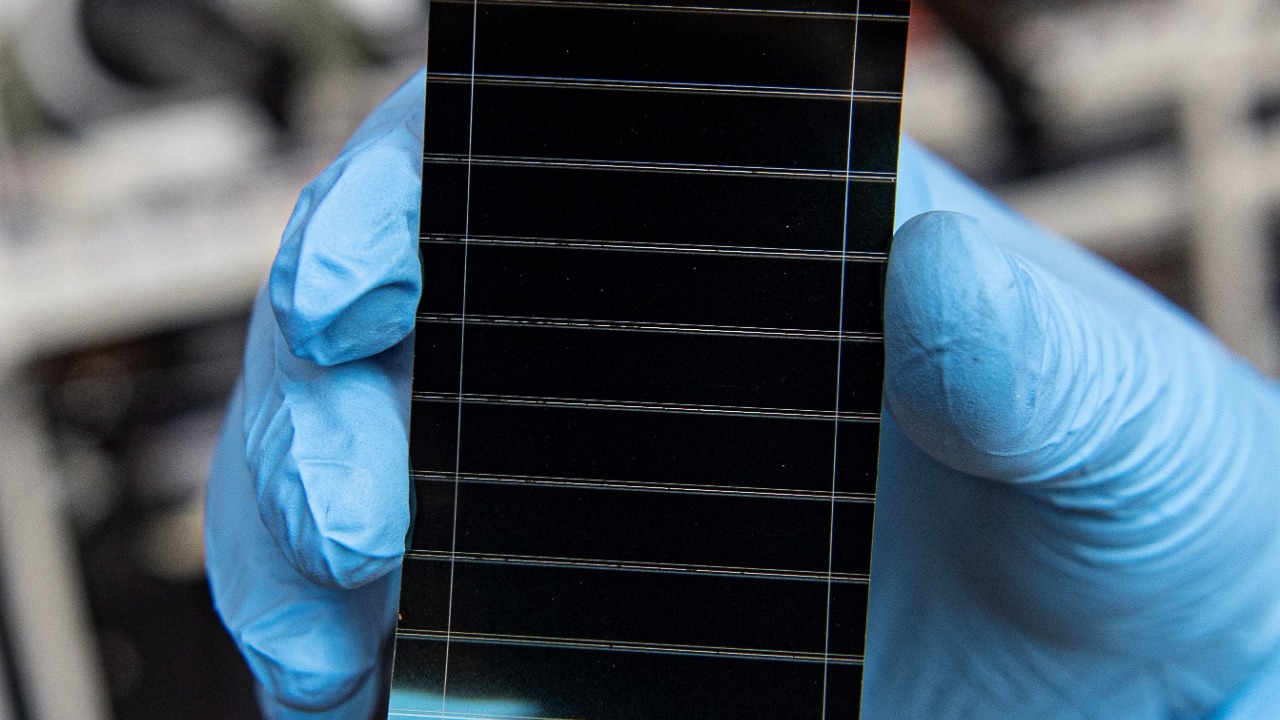

Visualizing the reactor and its potential deployment

While the chemistry happens at the nanoscale, the reactor designs being discussed are tangible pieces of equipment that could be installed at industrial sites. Images shared by the researchers show a compact reactor setup in which light is directed onto catalyst-coated surfaces while methane flows across them, illustrating how the system might be integrated into existing infrastructure. These visuals, presented alongside the claim that a new solar-powered catalyst can create a cleaner pathway to ethylene, help translate the lab-scale concept into something that plant operators and policymakers can picture in the field.

In those depictions, the reactor is designed to maximize the contact between light, catalyst, and gas, often through structured surfaces or modular panels that can be scaled up. The reporting notes that such reactors could, in principle, be mounted near flare stacks or on top of processing units, where they would intercept methane before it is burned. By pairing them with solar concentrators or integrating them into solar farms, operators could harness abundant sunlight to drive the conversion, potentially turning remote or stranded methane resources into a source of chemical revenue rather than a liability.

Parallel advances in methane activation and catalyst design

The push to turn methane into something more useful is not limited to solar-driven systems, and several research groups have reported catalysts that can activate methane under milder conditions than traditional processes. One detailed account describes a new catalyst that converts methane into liquid products and other valuable chemicals, emphasizing that it can operate at lower temperatures and with greater selectivity than many existing methods. The researchers behind that work frame it as a way to turn methane into something useful rather than simply burning it, and they present their new catalyst can turn methane into a range of products that could complement solar-driven ethylene routes.

Another report focuses on a sunlight-powered catalyst that transforms methane into a suite of valuable chemicals, not just ethylene, by carefully controlling the reaction pathways at the catalyst surface. In that case, the team highlights how they use light to drive the reaction and how they measure the distribution of products to optimize the system. They present their findings as evidence that a sunlight-powered catalyst can indeed convert methane into valuable chemicals under conditions that are far less energy intensive than conventional petrochemical routes, reinforcing the broader trend toward photon-driven methane upgrading.

From lab spectroscopy to industrial sensing and control

Behind these catalytic breakthroughs lies a significant amount of analytical work, including real-time monitoring of how methane and other gases interact with catalyst surfaces. One account of a commercial system describes how advanced optical spectroscopy can be used to track greenhouse gas conversions and optimize catalyst performance, highlighting the role of precise measurement in scaling up these reactions. The same report notes that a revolutionary catalyst uses sunlight to turn greenhouse gases into valuable chemicals, and it emphasizes that robust sensing technology is essential for controlling such processes in industrial environments.

In that context, the ability to monitor reaction intermediates and product distributions in real time allows researchers and operators to fine-tune conditions for maximum efficiency and selectivity. It also provides early warning of catalyst degradation or unwanted byproducts, which is crucial for maintaining safety and economic viability. By pairing solar-driven catalysts with sophisticated diagnostics, developers aim to shorten the path from laboratory demonstration to commercial deployment, ensuring that the promise of low-energy methane-to-ethylene conversion can be realized at scale rather than remaining a scientific curiosity.

What the latest studies say about efficiency and selectivity

Recent peer-reviewed studies have started to quantify how efficient these new catalysts can be and how selectively they can produce target molecules like ethylene. One report describes a system in which a carefully engineered catalyst converts methane into a mix of higher-value products with a focus on maximizing yield while minimizing unwanted carbon dioxide. The researchers present detailed measurements of conversion rates and product distributions, arguing that their new catalyst converts methane into useful chemicals with performance metrics that compare favorably to earlier attempts at photocatalytic methane activation.

Another study highlights a different catalyst formulation that also targets methane upgrading, emphasizing the importance of controlling reaction conditions such as temperature, pressure, and light intensity. In that work, the team reports that their new catalyst convert methane into useful products with improved stability and reduced energy input compared with conventional processes. Together, these studies suggest that the field is moving beyond proof-of-concept demonstrations toward systems that can be benchmarked, optimized, and eventually engineered for real-world applications, including the direct solar-driven production of ethylene from methane.

More from MorningOverview