Three-cylinder engines have emerged as a compelling choice in the automotive industry, offering a unique balance of efficiency and performance. These engines have evolved to address common issues and are increasingly being recognized for their surprising efficiency. However, like any technology, they come with their own set of pros and cons.

Fuel Efficiency Benefits

One of the key advantages of three-cylinder engines is their fuel efficiency. With fewer moving parts and reduced weight, these engines can achieve better fuel economy. This is particularly noticeable in compact vehicles, where the smaller engine size contributes to lower emissions and improved mileage. A recent analysis has highlighted these efficiency gains, underscoring the cost savings for daily drivers when compared to four-cylinder alternatives.

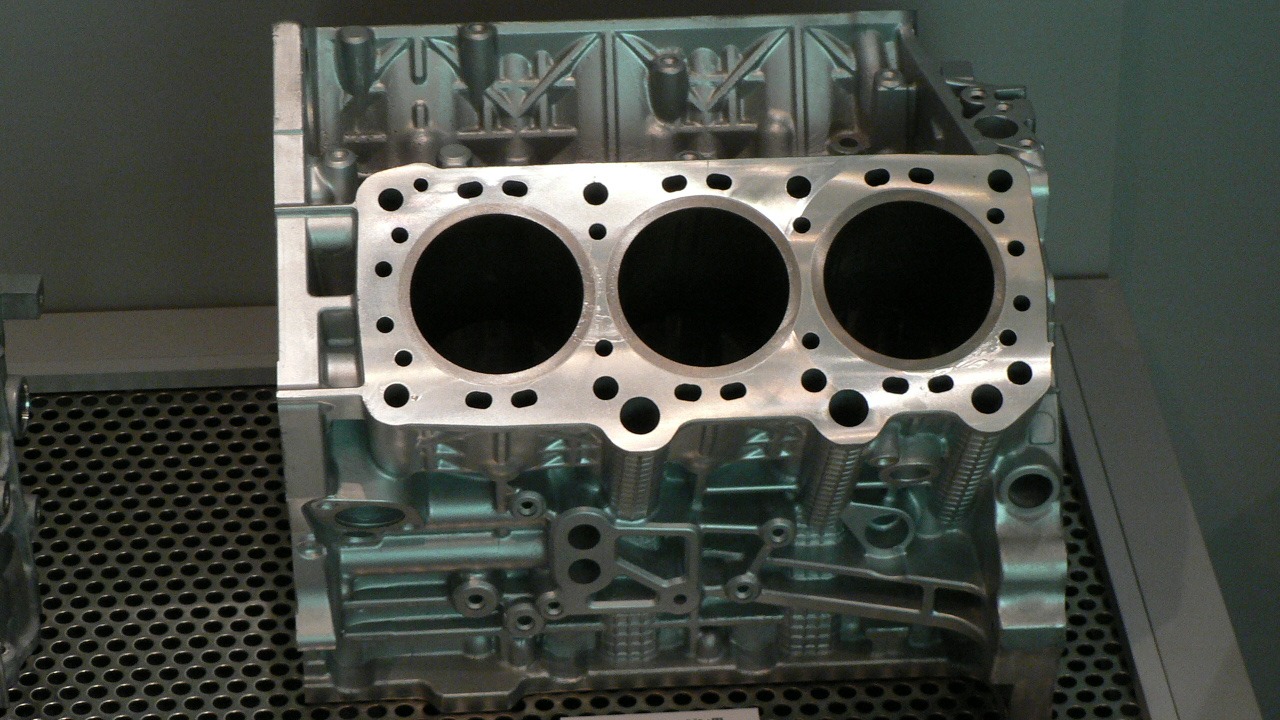

Compact Design Advantages

Another benefit of three-cylinder engines is their compact design. Their smaller footprint allows for easier integration into subcompact cars and hybrids. This design advantage extends to packaging benefits for transverse engine bays, as noted in a recent discussion on the pros and cons of these engines. The compact design also contributes to a reduction in overall vehicle weight without sacrificing space, making them a desirable choice for many modern vehicles.

Performance Potential

Despite their smaller size, three-cylinder engines have demonstrated impressive performance capabilities. Turbocharging plays a significant role in delivering torque comparable to larger engines in performance models. A roundup of the most powerful three-cylinder engines showcases the high-output capabilities of these engines, highlighting their potential in the performance segment of the automotive industry.

Vibration and NVH Challenges

However, three-cylinder engines are not without their challenges. One of the main issues is the inherent balance problem that causes more vibration than even-cylinder engines. This issue was highlighted in an October 2024 report. Countermeasures like counter-rotating balancers have been introduced to mitigate these vibrations and improve driver comfort. However, these traits can affect long-term ride quality in everyday use.

Reliability and Maintenance Considerations

When it comes to reliability and maintenance, three-cylinder engines have their unique considerations. Common wear points like timing chains and oil consumption can be issues in these engine designs. Routine upkeep and frequent servicing intervals can help mitigate these cons. While the BMW N20 engine, a four-cylinder engine, was initially mentioned as a case study, it’s important to note that the maintenance and reliability considerations for a three-cylinder engine may differ.

Cost and Manufacturing Pros

From a manufacturing perspective, three-cylinder engines offer several advantages. Their simpler design, with fewer components, can lead to lower production costs. This affordability extends to consumers, particularly in emerging markets where cost-effectiveness is a key consideration. Furthermore, the supply chain efficiencies in building three-cylinder powertrains can offer advantages over more complex alternatives.

Future Trends in Three-Cylinder Tech

Looking ahead, three-cylinder engines are set to play an increasingly important role in the automotive industry. Their evolving applications in electric-hybrid systems, as noted in a recent analysis, highlight their potential in this growing market. Performance benchmarks suggest that power gains are on the horizon, while ongoing refinements aim to address the vibration drawbacks associated with these engines. As technology continues to advance, the future of three-cylinder engines looks promising.

More from MorningOverview