Tesla and General Motors have adopted distinct cooling strategies for their electric motors, reflecting their unique engineering philosophies. Tesla integrates oil cooling directly into the motor design, while GM employs separate liquid cooling loops. These choices are driven by considerations of efficiency, cost, and durability, particularly in high-performance models like the Tesla Model 3 and GM’s Ultium-based vehicles, including the Chevrolet Bolt. Recent analyses reveal how these approaches impact motor longevity and thermal management without sacrificing power output (InsideEVs).

Tesla’s Oil Cooling Approach

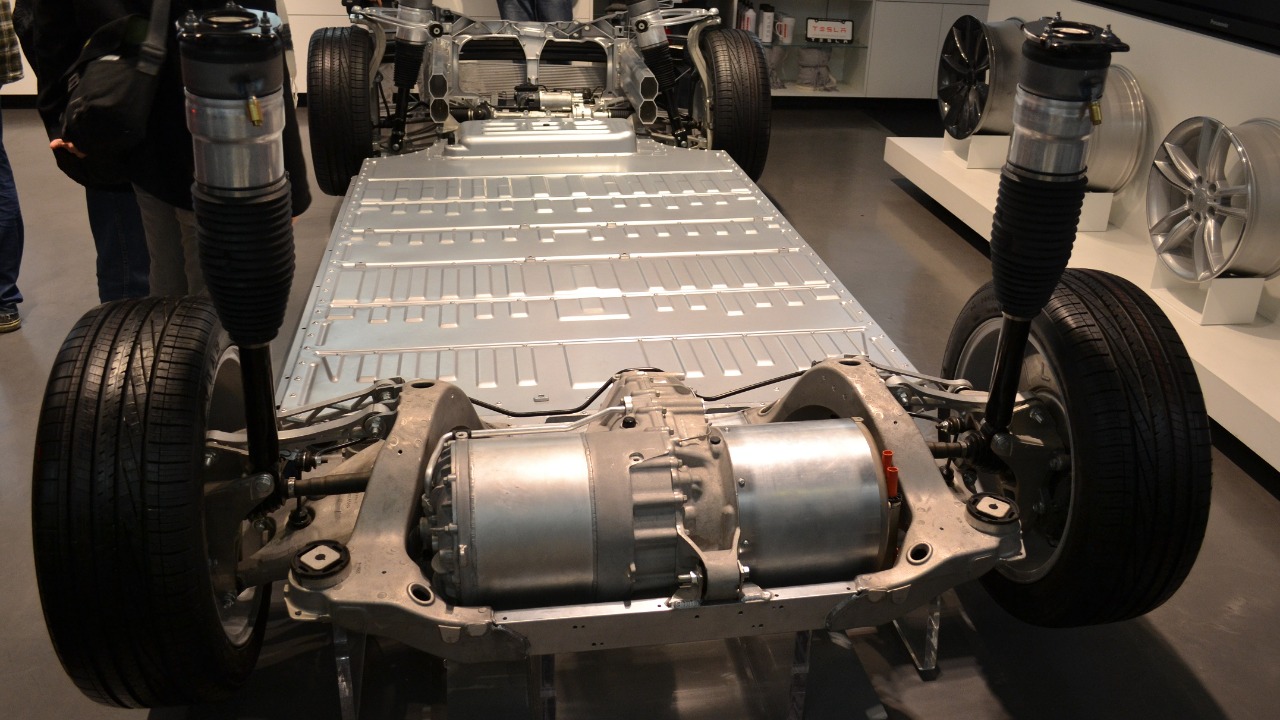

Tesla employs a distinctive method of cooling its permanent magnet motors by immersing them in oil. This technique allows for efficient heat transfer from the motor’s windings and rotor to the lubricant, which is then circulated through external coolers. By integrating cooling with lubrication, Tesla reduces the need for additional components, simplifying the assembly process and reducing overall weight. This approach is particularly evident in models like the Tesla Model S Plaid, where oil cooling supports sustained high torque output of up to 1,050 Nm without overheating, even during aggressive driving (InsideEVs).

The advantages of Tesla’s oil cooling system include a simpler assembly process and a lower weight compared to traditional water-based systems. This contributes to Tesla’s focus on compact, high-density motor designs, which are crucial for achieving the performance and efficiency standards the company is known for. The integration of cooling and lubrication not only enhances the motor’s performance but also aligns with Tesla’s broader strategy of maximizing power density and efficiency in its electric vehicles (InsideEVs).

General Motors’ Liquid Cooling Strategy

General Motors, on the other hand, utilizes dedicated glycol-water coolant loops that run parallel to the motor housing. This system cools the stator and electronics separately from the drivetrain lubricants, preventing contamination and allowing for precise temperature control. This strategy is implemented in GM’s Ultium platform vehicles, such as the GMC Hummer EV, where it maintains motor temperatures below 150°C under peak loads of 760 kW. This setup enhances reliability, particularly in off-road conditions where consistent performance is critical (InsideEVs).

GM’s approach facilitates modular battery-motor integration, enabling easier scaling across different models, from the Cadillac Lyriq to the Silverado EV. By separating the cooling systems, GM improves serviceability and thermal uniformity, which is particularly beneficial for diverse vehicle architectures, including front-wheel-drive setups in the Equinox EV. This modularity allows GM to efficiently adapt its cooling systems to various vehicle designs, supporting its broad range of electric vehicles (InsideEVs).

Engineering Trade-Offs Behind the Choices

Tesla’s preference for oil cooling is largely driven by its cost-effectiveness and reduced part count, which can achieve up to 20% higher power density in motors like those in the Cybertruck. However, this method may face challenges with oil degradation over time, potentially impacting long-term reliability. In contrast, GM’s liquid cooling strategy supports diverse vehicle architectures and allows for precise temperature control, which is crucial for maintaining performance across different models and driving conditions (InsideEVs).

Efficiency metrics further illustrate the impact of these cooling methods. Tesla’s motors can reach a peak efficiency of 97%, compared to GM’s 95%. This difference in efficiency can influence energy consumption and real-world ranges, with both manufacturers achieving ranges exceeding 500 km. These metrics highlight the importance of cooling strategies in optimizing the performance and efficiency of electric vehicles (InsideEVs).

Performance and Reliability Impacts

Tesla’s integrated cooling system enables faster acceleration, as demonstrated by the Model S’s ability to achieve 0-60 mph times under 2 seconds. This is achieved by minimizing thermal throttling during repeated launches, allowing for consistent high performance. On the other hand, GM’s system excels in heat dissipation for heavy-duty applications, such as towing up to 12,000 lbs in the Silverado EV. The coolant loops prevent efficiency drops in prolonged high-load scenarios, ensuring reliable performance under demanding conditions (InsideEVs).

Long-term reliability is another critical factor influenced by these cooling strategies. Tesla reports motor failure rates below 1% in the first 100,000 miles, while GM emphasizes coolant monitoring to extend warranty coverage to 8 years. These reliability metrics underscore the importance of effective cooling systems in maintaining the performance and longevity of electric vehicles, ultimately impacting consumer confidence and adoption rates (InsideEVs).

Industry-Wide Implications

The cooling strategies employed by Tesla and GM have broader implications for the electric vehicle industry. Competitors like Ford are adopting hybrid cooling methods in models such as the F-150 Lightning, blending oil and liquid cooling for versatility. This trend reflects the industry’s ongoing efforts to optimize cooling systems for various performance and efficiency needs. Furthermore, Tesla is reportedly experimenting with advanced oil formulations for its 2025 models to rival GM’s precision cooling in extreme climates (InsideEVs).

As cooling efficiency continues to improve, it contributes to standardized ranges of 300-400 miles, supporting the projected market growth of 30% annually through 2030. These advancements in cooling technology are crucial for enhancing the performance, reliability, and consumer appeal of electric vehicles, driving the industry’s evolution and expansion in the coming years (InsideEVs).