Researchers at the University of Illinois Chicago have made a significant breakthrough in the field of hydrogen fuel cells. They have developed a new type of cell that can operate at temperatures as low as -73°C, which is four times colder than the previous limit of around -30°C for similar batteries. This innovation, which uses a solid-state electrolyte made from hydrogen borohydride, enables denser energy storage and longer-lasting performance in electric vehicles, particularly in extreme cold conditions where traditional lithium-ion batteries falter. The details of this development were published in a study on October 10, 2023, in Nature Communications.

The Challenge of Cold Weather for EV Batteries

Traditional lithium-ion batteries used in electric vehicles face significant performance issues in cold weather. In sub-zero temperatures, these batteries can lose up to 20-30% of their range due to slowed chemical reactions and increased internal resistance. Hydrogen fuel cells have faced similar limitations, with prior models ceasing to function below -30°C because liquid electrolytes freeze, halting ion transport. This performance drop has been a significant barrier to the adoption and reliability of electric vehicles in regions like the northern U.S. or Canada, where winter temperatures often drop below -20°C.

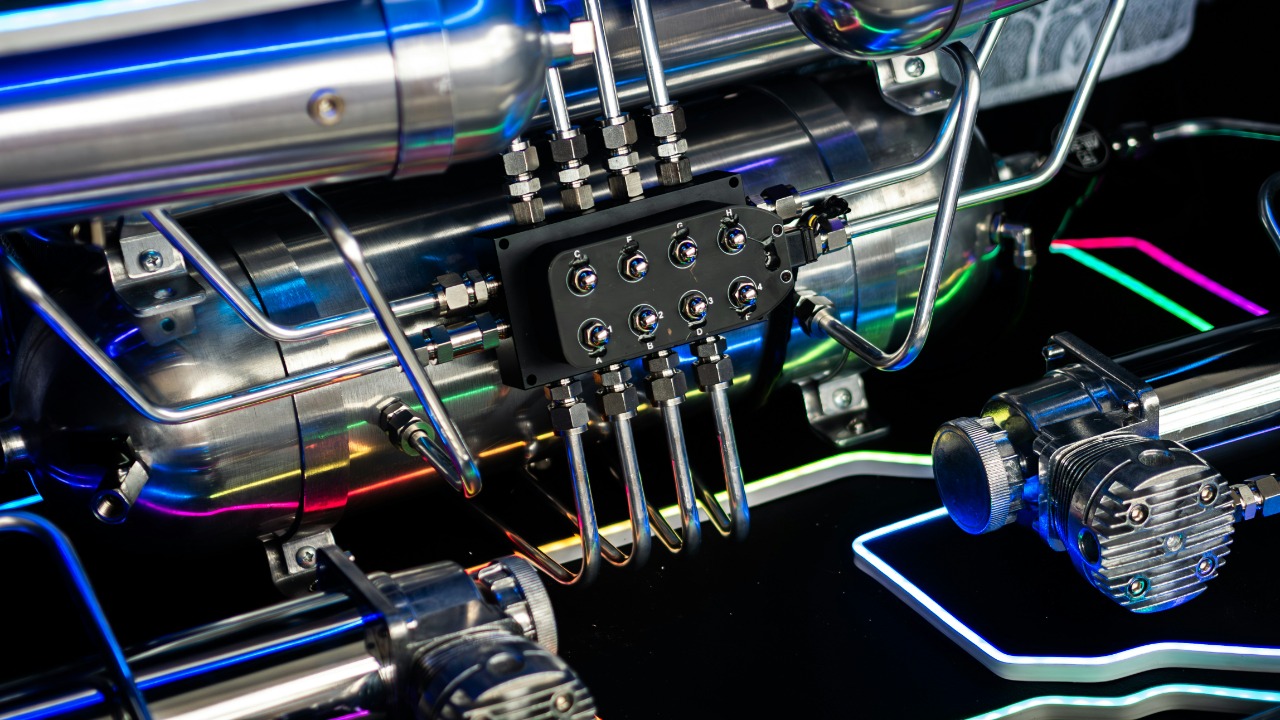

Breakthrough in Solid-State Hydrogen Technology

The new battery developed by the team led by Zhenzhen Wang, a researcher at the University of Illinois Chicago, employs a solid electrolyte derived from sodium borohydride combined with hydrogen. This combination allows the battery to remain conductive at -73°C or 200 Kelvin. The team engineered this material to prevent freezing while maintaining high ionic conductivity. Unlike liquid-based systems, the solid-state design eliminates the risk of electrolyte leakage and enables operation in a wider temperature range without performance degradation.

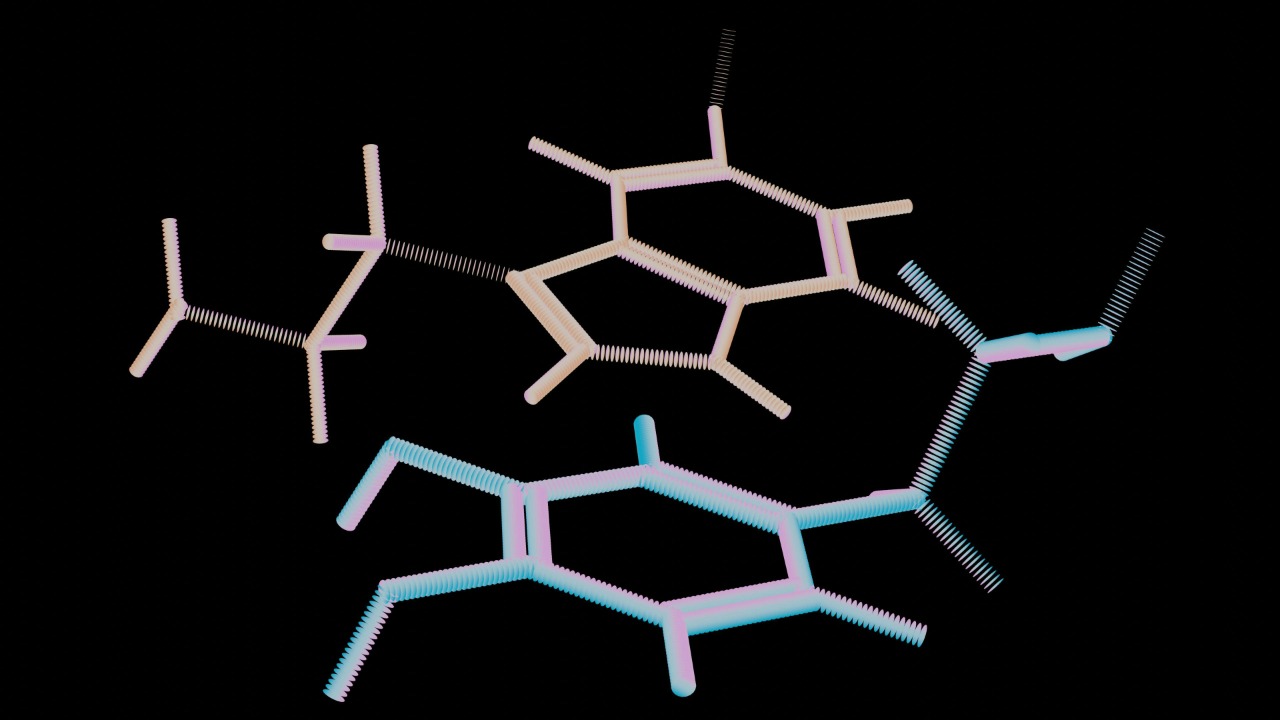

How the Hydrogen Borohydride Electrolyte Works

The electrolyte in this new battery facilitates the movement of hydrogen ions through a boron-hydrogen framework. This framework remains stable and active even at cryogenic temperatures like -73°C. During discharge, the battery converts stored hydrogen into electricity via an electrochemical reaction that generates water as a byproduct. The efficiency of this process is preserved down to 200 Kelvin. The researchers tested the cell’s conductivity and found it retained 90% of its room-temperature performance at -30°C and continued functioning reliably at -73°C.

Advantages for Energy Density in EVs

By operating in extreme cold without energy loss, the new battery allows for higher hydrogen storage density. This could potentially increase the range of electric vehicles by 20-50% compared to current lithium-ion packs in winter conditions. The solid-state structure of the battery also enables more compact designs, reducing the overall weight and volume of battery packs while achieving energy densities up to 1,000 watt-hours per liter. “This could revolutionize how we power vehicles in cold climates, making hydrogen a viable alternative to lithium for long-haul and heavy-duty applications,” stated Zhenzhen Wang.

Testing Results and Performance Metrics

In lab tests conducted at the University of Illinois Chicago, the prototype fuel cell delivered consistent power output from 25°C down to -73°C, with no freezing observed in the electrolyte. The battery achieved a specific energy of 500 watt-hours per kilogram at low temperatures, surpassing previous hydrogen cells that dropped to below 200 Wh/kg below -20°C. Cycle life testing showed over 100 charge-discharge cycles with less than 5% capacity fade, even after exposure to -50°C for extended periods.

Implications for Electric Vehicle Adoption

This technology addresses a key barrier for electric vehicles in cold-weather markets, such as the Midwest U.S. and Europe, where temperature-related range anxiety has slowed sales growth. Integration with existing hydrogen infrastructure could enable faster refueling times—under 5 minutes—compared to hours for lithium-ion charging in the cold. The October 10, 2023, publication in Nature Communications positions this as a scalable solution for next-generation electric vehicles, potentially reducing reliance on rare-earth materials in batteries.

Future Developments and Challenges

Scaling production of the hydrogen borohydride electrolyte remains a hurdle, as current synthesis is lab-based and requires optimization for cost-effective manufacturing. The researchers plan to test prototypes in real-world electric vehicle simulations, targeting commercial viability by 2027 through partnerships with automakers like Toyota or Hyundai. Safety enhancements, such as improved hydrogen containment to prevent leaks, will be critical before widespread deployment in consumer vehicles.

Overall, this development represents a significant step forward in the field of electric vehicle technology, offering the potential for more efficient and reliable performance in cold climates. However, further research and development are needed to bring this technology to market.