Scientists have developed a groundbreaking method to grow metal objects using vat photopolymerization, a process that allows for the creation of intricate structures beyond the capabilities of traditional manufacturing. This innovation parallels natural phenomena, such as potential leaks from Earth’s core that might influence metallic compositions on the planet’s surface. Additionally, advances in transmuting base metals like lead into more valuable ones echo historical alchemy but through modern scientific means. These developments promise to reshape our understanding of metal production and its applications across various industries.

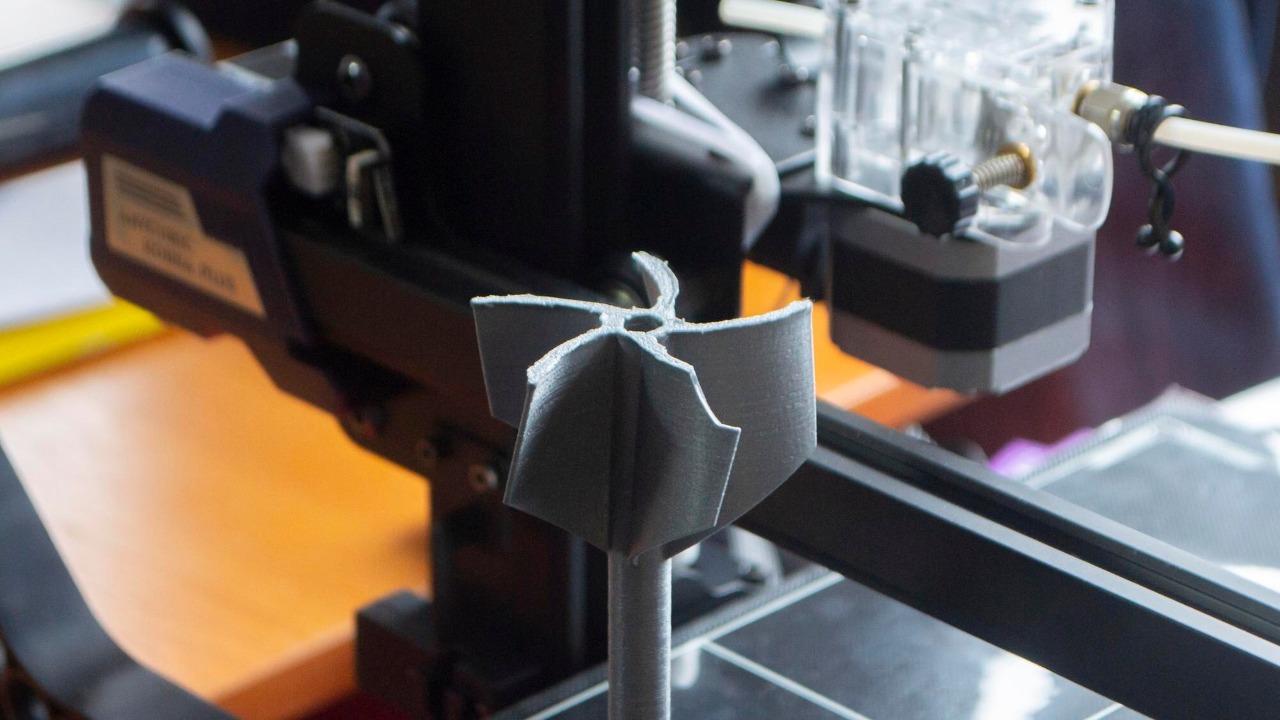

The Basics of Vat Photopolymerization for Metal Growth

Vat photopolymerization is a sophisticated technique that involves curing a photosensitive resin mixed with metal particles using light, building solid metal forms layer by layer. This method differs significantly from conventional 3D printing, which typically uses plastic or metal filaments. The process begins with a vat filled with a liquid photopolymer resin infused with metal particles. A light source, often a laser, selectively cures the resin, solidifying it into the desired shape. This approach allows for the creation of complex geometries that are difficult to achieve with traditional manufacturing methods (Popular Mechanics).

The materials involved in vat photopolymerization include metal-infused photopolymers, which are crucial for the process. After the initial curing, the objects undergo post-processing steps such as sintering. Sintering involves heating the object to a temperature below its melting point to increase its density and achieve pure metal properties. This step is essential to ensure that the final product has the necessary strength and durability for practical applications (Popular Mechanics).

Initial prototypes created using this method have demonstrated remarkable precision, making them ideal for applications in aerospace and medical fields. These industries require components with complex geometries and high precision, which vat photopolymerization can provide. For instance, custom implants and lightweight engine parts are just a few examples of how this technology can be applied to meet specific industry needs (Popular Mechanics).

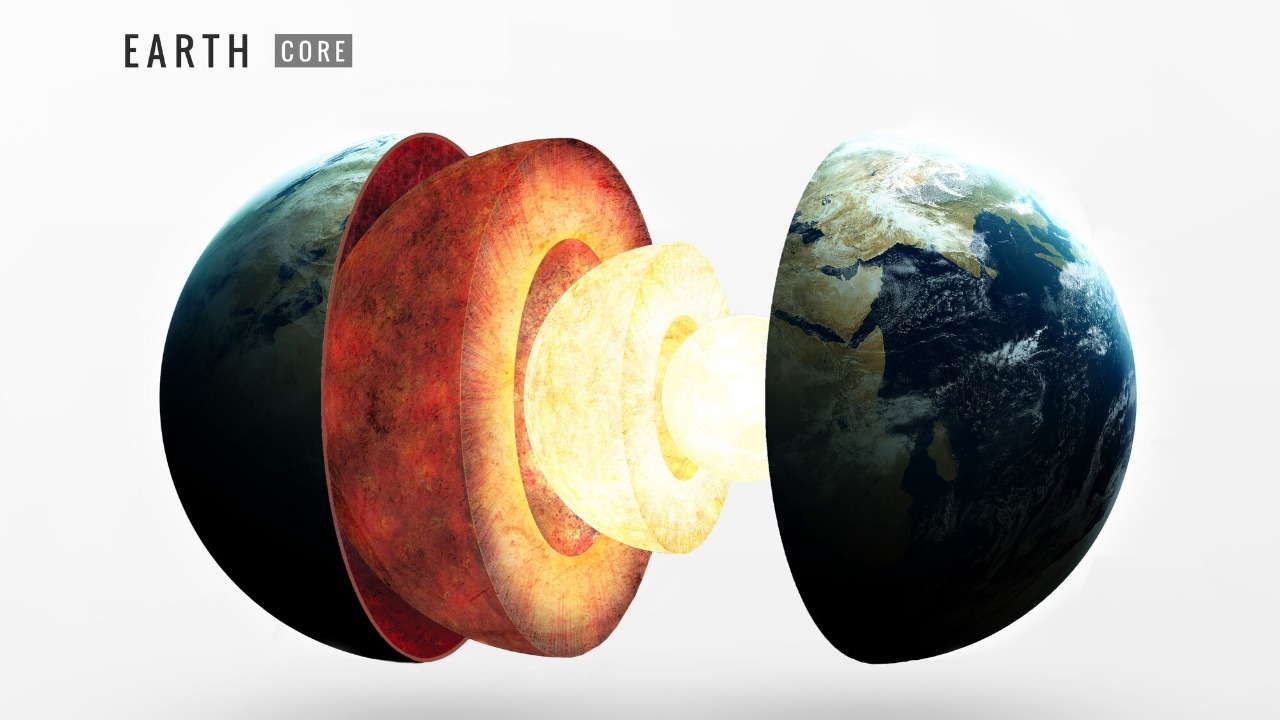

Natural Processes Mimicking Metal Formation

Recent studies suggest that Earth’s core may be leaking elements, contributing to metallic deposits on the planet’s surface. Seismic data and geochemical analysis indicate that there is an ongoing material flux from deep within the Earth. This phenomenon mirrors the lab-based methods of metal growth, albeit occurring over millions of years. The natural “growth” of metals through geological processes, such as crystallization in magma, provides valuable insights into how metals can form and migrate over time (AOL).

Specific studies have observed mantle plumes, which are upwellings of hot rock from deep within the Earth, that carry iron and other metals toward the surface. These observations highlight the dynamic nature of Earth’s interior and its potential to influence surface geology. Understanding these processes can inspire new approaches to alloy compositions and metal production, drawing parallels between natural and artificial methods of metal formation (AOL).

Modern Alchemy: Transmuting Base Metals

In the realm of modern science, experiments have been conducted to transmute base metals like lead into gold using particle accelerators or nuclear reactions. These experiments, while fascinating, are not yet practical for large-scale production due to the immense energy requirements and the minuscule amounts of gold produced. The process involves altering the atomic structure of lead to transform it into gold, a feat that echoes the dreams of ancient alchemists but remains largely a scientific curiosity rather than an industrial breakthrough (LinkedIn).

The economic implications of such transmutation are currently limited, as the costs and energy demands far outweigh the value of the gold produced. However, these experiments highlight the potential for future advancements in material science that could one day make such processes more feasible. For now, the focus remains on understanding the fundamental principles behind transmutation and exploring its potential applications in niche areas (LinkedIn).

Applications and Future Potential

The industrial applications of grown metals are vast, with potential uses in creating custom implants and lightweight engine parts. These components benefit from the precision and strength improvements offered by vat photopolymerization, which can produce parts with superior mechanical properties compared to traditionally forged alternatives. This technology is particularly valuable in industries where weight reduction and structural integrity are critical, such as aerospace and automotive sectors (Popular Mechanics).

Integrating insights from natural metal processes, such as core leaks, could inspire new alloy compositions that mimic Earth’s deep formations. By studying the natural migration of metals from the core to the surface, scientists can develop innovative materials that replicate these properties, potentially leading to stronger and more resilient metal products (AOL).

Looking ahead, advancements in transmutation and metal growth techniques hold promise for sustainable metal production. While challenges remain in scaling these processes for widespread use, the environmental benefits of reducing reliance on traditional mining methods are significant. As research continues, these technologies could pave the way for more efficient and eco-friendly approaches to metal production, transforming industries and reducing the environmental impact of metal extraction (LinkedIn).