Researchers at Rice University have made a significant breakthrough in the field of lithium extraction, developing a nanoengineered membrane that filters lithium from brines more efficiently and cleanly. This development is set to revolutionize battery production, with nanotechnology and artificial intelligence (AI) playing a pivotal role in enabling sustainable lithium extraction processes.

The Nanoengineered Membrane Technology

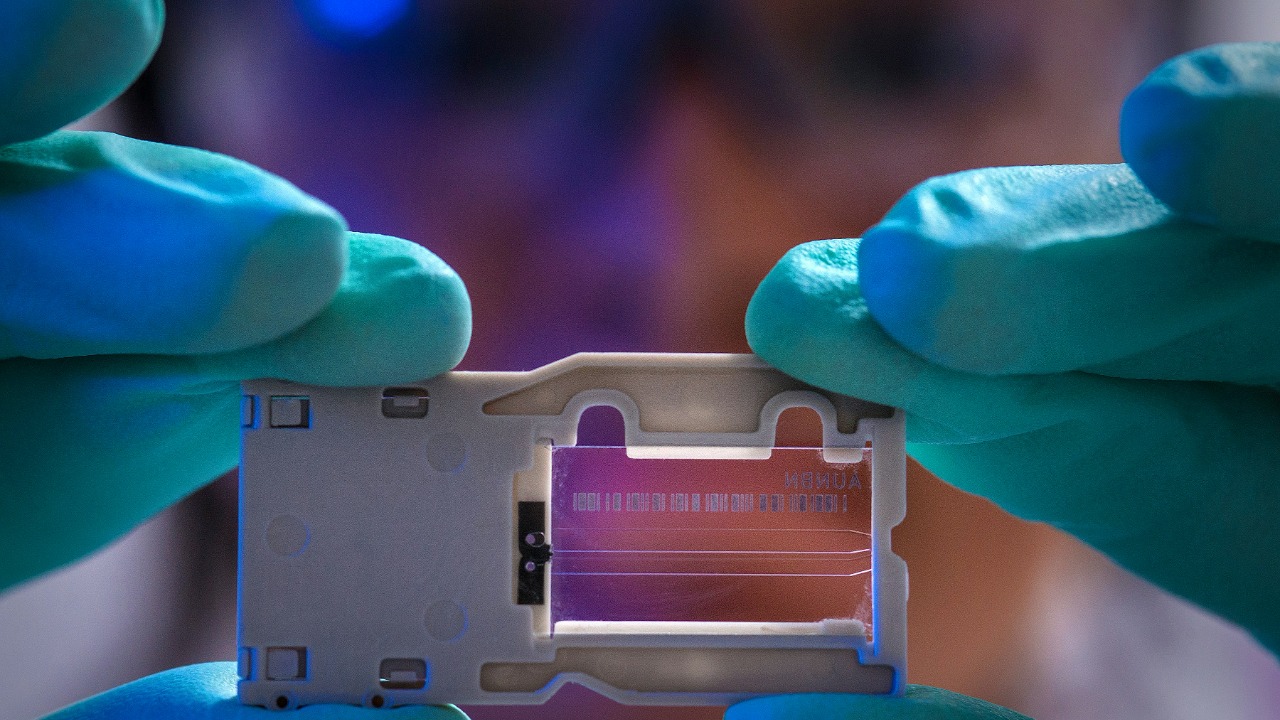

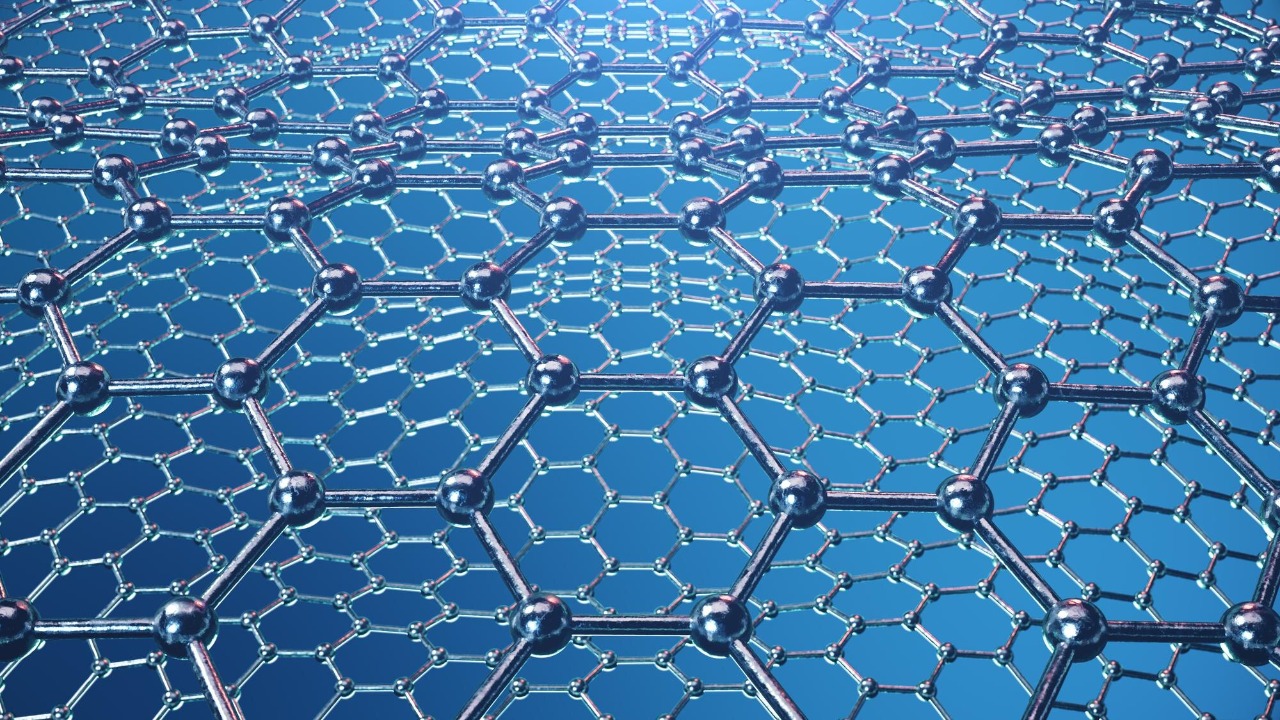

The core design of the nanoengineered membrane is centered around its ability to filter lithium from brines at a faster rate than traditional methods. This speed is achieved through the unique properties of the membrane, which has been engineered at the nanoscale to optimize its filtration capabilities (Nanowerk).

Not only is the membrane faster, but it also results in cleaner extraction. The nanoengineered membrane reduces impurities in the lithium output, ensuring a higher quality product for use in various applications (Nanowerk). This groundbreaking technology was developed by researchers at Rice University, marking a significant advancement in brine-based lithium recovery (Interesting Engineering).

Applications in Battery Production

The membrane’s role in lithium extraction is particularly beneficial for battery manufacturing. Its speed advantages mean that lithium can be extracted and processed more quickly, reducing the time it takes to produce batteries (Interesting Engineering).

Cleaner lithium filtration from brines also has the potential to streamline supply chains for electric vehicle batteries. By providing a more efficient and cleaner source of lithium, the nanoengineered membrane could help to meet the increasing demand for lithium in global battery production.

Integration of AI in Lithium Extraction

AI is playing a crucial role in enhancing the efficiency of nanotech-based lithium extraction processes. By analyzing data and making predictions, AI can optimize the performance of the nanoengineered membrane during brine filtration (WebProNews).

AI’s role extends beyond just improving efficiency. It also contributes to sustainability by improving lithium recovery rates and managing resources more effectively. This integration of AI and nanotechnology is driving a new era of efficient and sustainable lithium extraction.

Sustainability Benefits of the Approach

The environmental advantages of using the nanoengineered membrane for lithium extraction are significant. Faster and cleaner extraction means less waste and lower water usage compared to traditional methods (Nanowerk).

Furthermore, the integration of nanotech and AI contributes to more sustainable lithium sourcing from brines overall. By optimizing extraction processes and reducing waste, this approach is paving the way for a more sustainable future in lithium extraction (WebProNews).

Recent Developments and Timeline

The announcement of the nanoengineered membrane marks a key advancement in filtration technology. This development, announced recently, is set to revolutionize the way lithium is extracted from brines (Nanowerk).

Just prior to this, there was an update on the membrane’s application in battery production. This update highlighted the membrane’s potential in clean energy applications (Interesting Engineering). Earlier, a report on the integration of nanotech and AI in lithium extraction laid the foundation for these recent advancements (WebProNews).

Challenges and Future Prospects

Despite the promising developments, there are potential scalability issues in deploying the nanoengineered membrane for widespread brine processing. Further research is needed to address these challenges and to integrate AI more deeply with membrane technology for lithium production.

However, the future prospects are bright. The innovations in nanotechnology and AI are set to have a significant impact on the growth of the battery industry, potentially revolutionizing the way we produce and use energy.