Recent breakthroughs in scientific research have opened up a fascinating world where materials can “heal” themselves. A pioneering group of scientists has successfully developed a metal with self-healing properties, capable of recovering from damage without human intervention. This innovative development could have far-reaching implications across various industries, including aerospace and robotics.

The Science Behind Self-Healing Metals

Self-healing materials are not a new concept in material science. However, the creation of a self-healing metal is a significant breakthrough. At the core of the technology is the understanding that materials can be designed in such a way that they respond to changes in their environment, such as damage, and initiate a healing process. This concept borrows heavily from biological systems, where damage triggers a healing response.

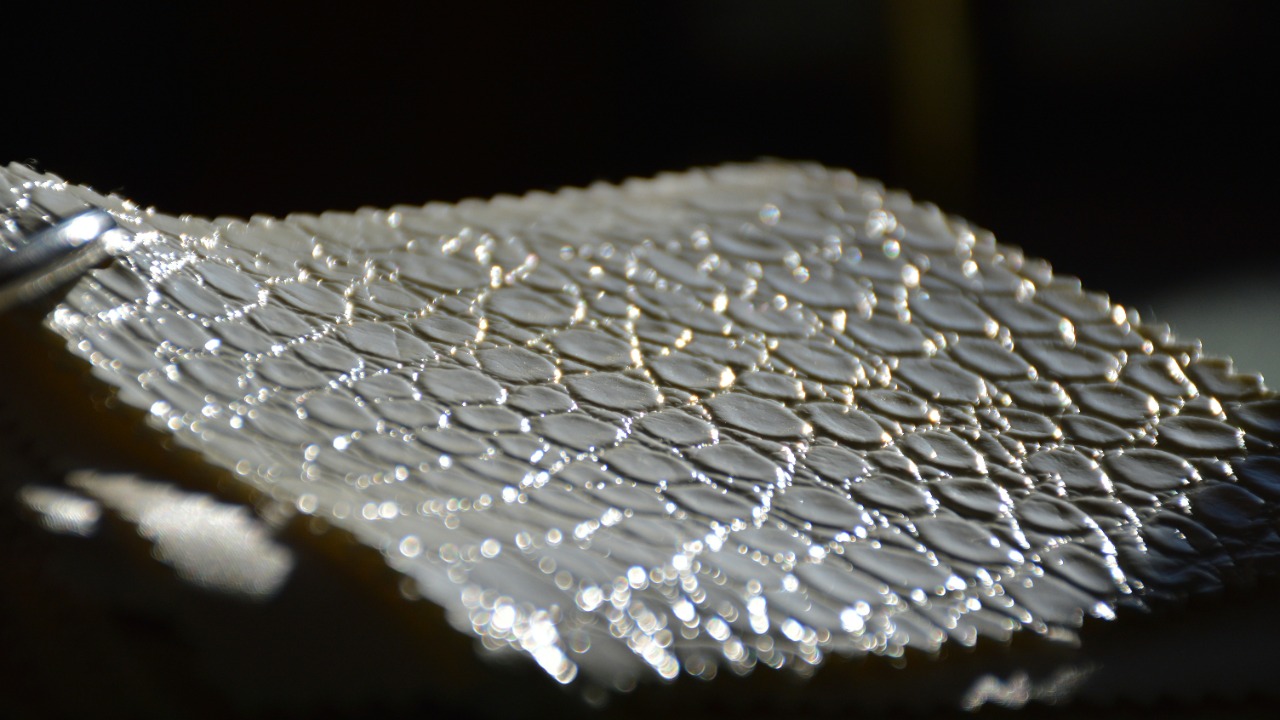

Scientists have achieved this feat in metals by introducing nano particles into the metal matrix. These particles play a crucial role in healing the metal when it’s damaged. More information about these scientific breakthroughs can be found in these research books.

How Self-Healing Metals Work

The self-healing process begins when the metal is damaged, triggering the release of the healing agents contained within the nano particles. These agents flow to the damaged area and react with the surrounding metal to form a ‘scar’ of new material. This effectively seals the damage and restores the structural integrity of the metal.

Nano particles are the key to the self-healing process. They are engineered to be sensitive to changes in the metal’s environment and to respond accordingly. When the metal is damaged, the nano particles release their healing agents, enabling the metal to repair itself. More details of how these nano particles function can be found here.

Potential Applications of Self-Healing Metals

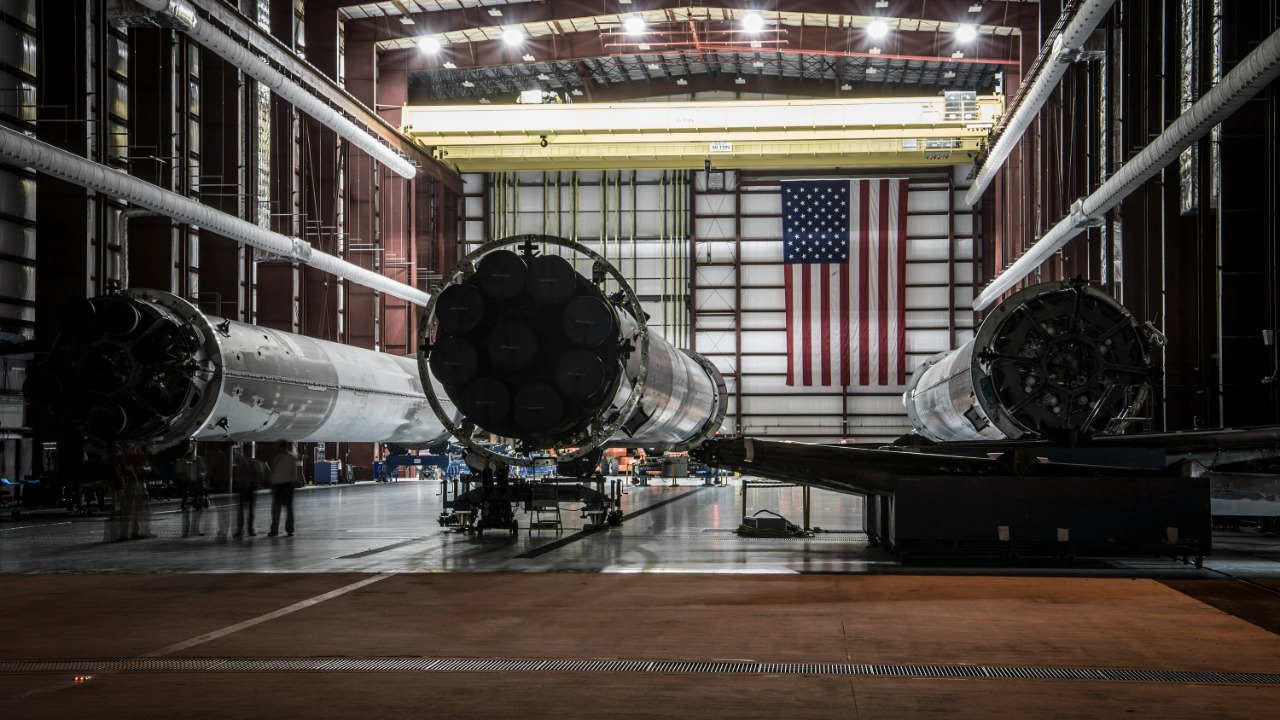

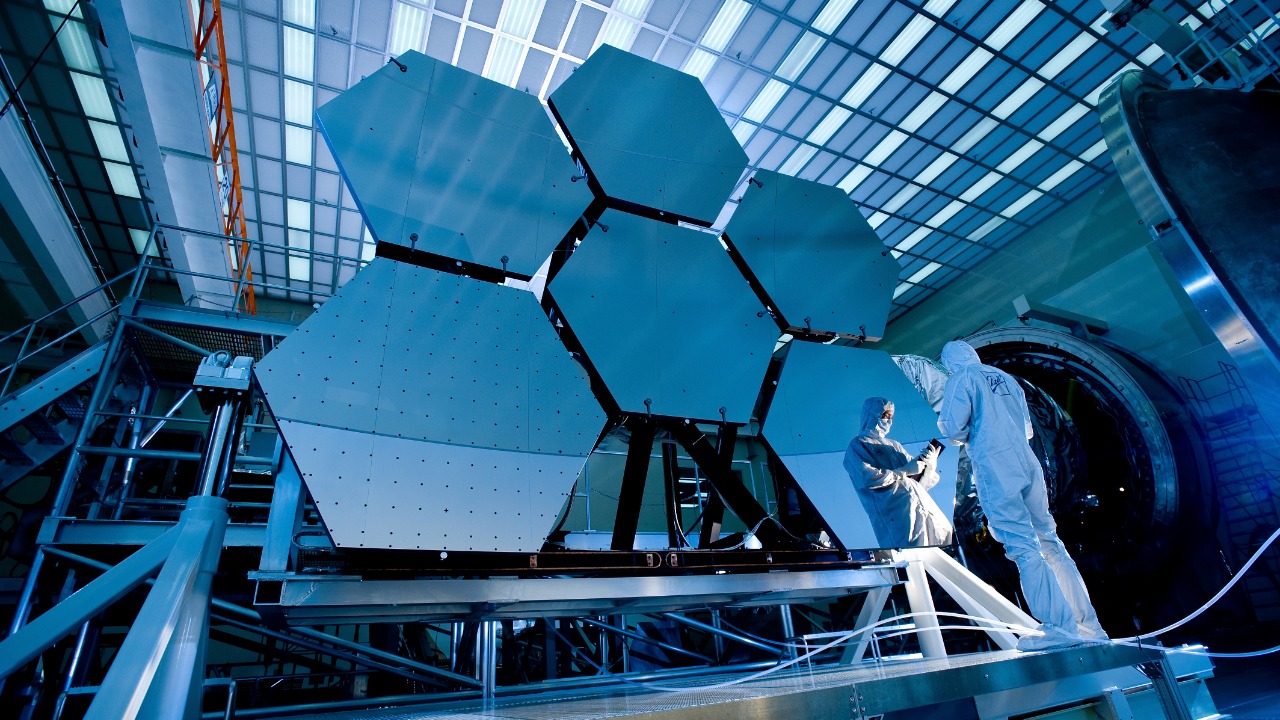

One of the most significant potential applications for self-healing metals is in the aerospace industry. Aircraft frequently experience wear and tear due to harsh operating conditions. The use of self-healing metals could potentially reduce maintenance costs and improve safety by ensuring that damage is repaired promptly and effectively.

Furthermore, the field of robotics could also greatly benefit from self-healing metals. Robots often operate in challenging environments that can cause damage. Self-healing metals could increase the lifespan of robots and reduce maintenance costs, as detailed in this research article and editorial.

Advantages and Challenges of Self-Healing Metals

The advantages of self-healing metals are quite significant. For one, they could dramatically reduce maintenance costs as the need for human intervention to repair damage would decrease. This could lead to increased safety, especially in industries like aerospace where even minor damage can have severe consequences. Moreover, the lifespan of materials could also be extended, contributing to sustainability efforts.

Despite the many advantages, there are still challenges to overcome. The cost of producing self-healing metals is currently high, and there are still scalability issues to address. Furthermore, the technology is still in its early stages, and more research is needed to fully understand and optimize the self-healing process.

Future Implications and Developments

Looking to the future, the creation of self-healing metals could revolutionize the manufacturing industry. It would pave the way for more durable, longer-lasting products, and could significantly reduce the resources needed for maintenance. In a world where sustainability is becoming increasingly important, these benefits could have a profound impact.

Research into self-healing materials is ongoing, with scientists around the world working to improve the technology and discover new applications. It’s an exciting field with the potential to transform numerous industries, and it will be fascinating to watch as it continues to develop.