A recent breakthrough in EV battery recycling technology has the potential to revolutionize the sustainability of electric vehicles. This groundbreaking method promises to significantly increase the recycling rate of lithium and other valuable materials, addressing one of the major challenges in the EV industry. As the demand for electric vehicles continues to rise, this innovation could play a crucial role in reducing environmental impact and conserving resources.

The Current State of EV Battery Recycling

Existing recycling methods for electric vehicle (EV) batteries have long faced scrutiny due to their limitations and inefficiencies. Traditional approaches often involve energy-intensive processes that result in low recovery rates of critical materials like lithium, cobalt, and nickel. These processes typically require high temperatures and complex chemical treatments, which not only consume substantial amounts of energy but also lead to significant waste generation. As a result, only a small fraction of the materials used in EV batteries are efficiently reclaimed, leaving much room for improvement.

The environmental and economic challenges posed by current recycling technologies are significant. Improper disposal of EV batteries can lead to harmful environmental impacts, including soil and water contamination from toxic materials. Moreover, the economic implications of inefficient recycling processes extend to increased costs for raw materials and a dependency on finite resources. As the demand for EVs continues to grow, these challenges underscore the urgent need for more effective and sustainable recycling solutions that can mitigate environmental damage and reduce costs associated with battery production.

Breakthrough Technology in Recycling

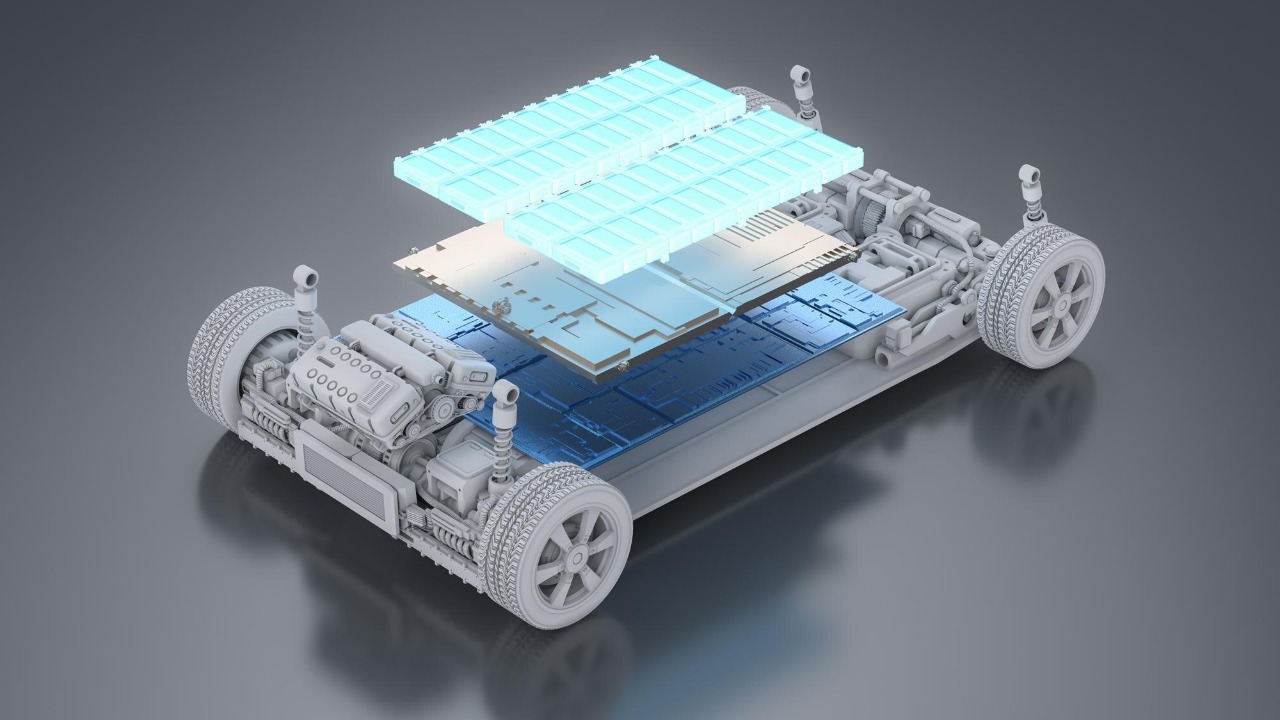

The recent breakthrough in EV battery recycling introduces an innovative method that promises to address the shortcomings of existing technologies. This new approach centers on a process known as hydrometallurgical recycling, which utilizes advanced chemical treatments to achieve higher recovery rates of lithium and other valuable materials. Unlike traditional pyrometallurgical methods, this technique operates at lower temperatures and reduces energy consumption, making it a more environmentally friendly alternative. By enabling the extraction of nearly 100% of lithium from spent batteries, this technology represents a significant leap forward in recycling efficiency.

The potential impact of this breakthrough on the EV industry is substantial. By improving the efficiency and sustainability of battery recycling, this technology could reduce the overall environmental footprint of electric vehicles. It aligns with the industry’s goals of creating a circular economy for battery materials, which could lessen the reliance on new raw material extraction and promote resource conservation. The implementation of this technology on a broader scale could also inspire further innovations and investments in the EV sector, paving the way for more sustainable transportation solutions.

Environmental Benefits and Sustainability

The introduction of this new recycling method brings significant environmental benefits by minimizing waste and conserving valuable resources. By enhancing the recovery rates of critical materials, the technology reduces the need for mining and extraction of new raw materials, which often have detrimental environmental effects. This advancement contributes to a more sustainable lifecycle for EV batteries, promoting the concept of a closed-loop system where materials are continuously reused and recycled.

Moreover, the reduced energy consumption associated with this recycling process leads to a lower carbon footprint. Traditional recycling methods often involve energy-intensive steps that contribute to greenhouse gas emissions. In contrast, the new technology utilizes more efficient chemical treatments that require less energy, thereby decreasing the overall carbon emissions associated with battery recycling. As a result, the widespread adoption of this method could significantly contribute to the global effort to combat climate change by reducing the environmental impact of EV production and disposal.

Economic Implications

The cost-effectiveness of the new recycling technology has the potential to transform the economic landscape of the EV industry. By reducing the energy requirements and improving recovery rates, this method could lower the overall costs associated with recycling. Consequently, the production costs for electric vehicles could decrease, making them more economically viable for consumers and manufacturers alike. This cost reduction could accelerate the adoption of EVs, further supporting the transition to sustainable transportation.

In addition to reducing costs, the improved recycling technology could have significant implications for the global supply chain. By increasing the availability of recycled materials, the technology could reduce the dependency on new raw material extraction, which often faces geopolitical and economic challenges. This could lead to greater stability in the supply chain, ensuring a more reliable and sustainable source of materials for battery production. The enhanced recycling capabilities could also stimulate new economic opportunities in the recycling sector, creating jobs and driving innovation.

Future Prospects and Industry Adoption

The timeline for the adoption of this breakthrough recycling technology in the EV industry remains a subject of speculation. However, several factors could influence the speed at which this technology is implemented. Regulatory support and incentives, coupled with growing consumer demand for sustainable solutions, could accelerate the industry’s transition to more efficient recycling methods. Additionally, collaborations between technology developers, manufacturers, and policymakers could facilitate the integration of this innovation into existing recycling infrastructures.

Despite the promising potential of the new technology, several challenges must be addressed to achieve widespread adoption. Financial investments and technological advancements are necessary to scale up the recycling processes and integrate them into existing systems. Additionally, public awareness and education about the benefits of improved recycling methods could play a crucial role in driving demand and support for sustainable practices. As the industry navigates these challenges, opportunities for further innovation and investment in EV battery recycling will likely emerge, paving the way for a more sustainable and economically viable future for electric vehicles.