Recent advancements in polymer science have introduced a new lightweight material that could potentially replace metals in airplane manufacturing. This innovative polymer offers significant benefits in terms of weight reduction, strength, and environmental impact, setting the stage for a transformative shift in the aerospace industry.

The Science Behind the New Polymer

The breakthrough in polymer science revolves around a novel 2D polymer structure that showcases unique characteristics, including remarkable strength and lightweight properties. Unlike traditional materials such as aluminum and titanium, this polymer is designed at the molecular level, allowing for a more efficient arrangement of atoms that results in enhanced mechanical properties. The polymer’s structure is akin to a sheet-like lattice, providing exceptional tensile strength and resistance to deformation.

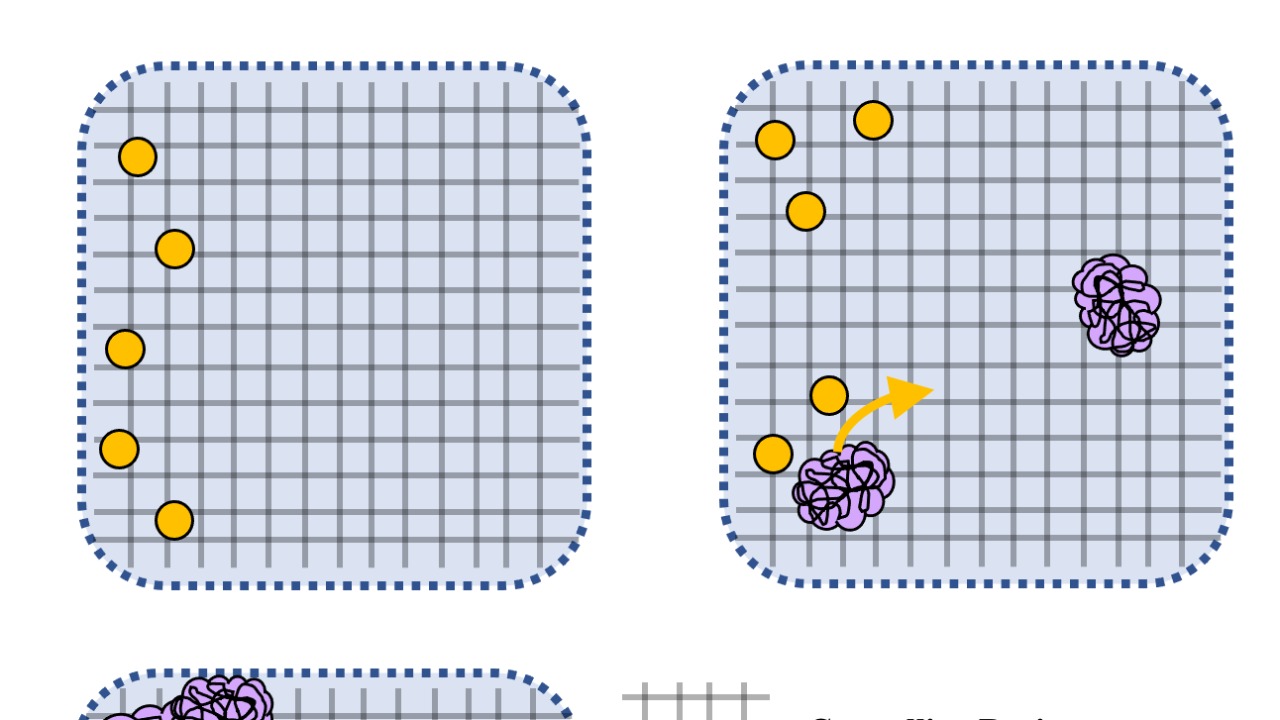

Development of this polymer involved several key milestones, beginning with extensive laboratory testing to evaluate its fundamental properties. Researchers conducted a series of rigorous evaluations to assess its strength, durability, and weather resistance. Real-world applications followed, with prototypes being tested under various environmental conditions to ensure their reliability. The iterative process of testing and refinement has been crucial in validating the polymer’s potential as a viable alternative to metals used in aerospace engineering.

Advantages of Polymer Over Metal

One of the most compelling advantages of this new polymer is its potential for substantial weight reduction, which directly translates to improved fuel efficiency. Aircraft weight plays a crucial role in fuel consumption, and the introduction of lighter materials like this polymer can lead to significant savings. For long-haul flights, where every kilogram counts, the use of lighter materials can reduce operating costs and enhance the aircraft’s range.

In terms of durability and strength, studies have shown that the polymer can rival, if not surpass, the performance of traditional metals. Data from comparative analyses indicate that the polymer maintains its structural integrity under stress, offering potential for reduced maintenance costs and longer aircraft lifespans. The resilience of the polymer in harsh environmental conditions further underscores its suitability for aerospace applications, promising enhanced safety and reliability.

Environmental Impact and Sustainability

The environmental benefits of this polymer are also noteworthy. The manufacturing process for the polymer is designed to minimize carbon emissions, offering a lower carbon footprint compared to traditional metal production. The use of this polymer could significantly reduce the greenhouse gas emissions associated with airplane manufacturing, contributing to more sustainable aviation practices.

Furthermore, the polymer’s recyclability presents an environmentally friendly alternative to metal recycling. The end-of-life processes for this material are more efficient, allowing for easier breakdown and reuse. This could lead to a more sustainable lifecycle for airplanes, aligning with global efforts to improve environmental responsibility in industrial practices. The polymer’s ability to be repurposed without significant degradation ensures that it not only offers immediate benefits but also supports long-term sustainability goals.

Challenges and Considerations in Adoption

Despite its promising attributes, the adoption of this new polymer in aviation faces several technological and engineering challenges. Integrating it into existing airplane designs requires significant adjustments, as current manufacturing processes and equipment are optimized for metals. The transition to polymer-based components would necessitate the development of new manufacturing techniques and potentially substantial investments in new technologies.

Regulatory and safety concerns also play a critical role in the material’s adoption. The aviation industry is governed by stringent regulations, and the introduction of a new material demands comprehensive testing and validation to ensure safety standards are met. The regulatory landscape for new materials in aviation is complex, requiring thorough safety testing and approval processes. This can pose a significant barrier to entry for new technologies, though it is a necessary step to ensure passenger safety and industry reliability.

The Future of Aviation Materials

The introduction of this new polymer holds the potential to revolutionize airplane design and innovation. As the industry explores the possibilities of using this material, we may witness the emergence of aircraft designs that prioritize efficiency and sustainability. The polymer’s properties offer new opportunities for hybrid designs, combining polymers with traditional metals to optimize performance and cost-effectiveness.

The outlook for the aerospace industry is optimistic, with predictions suggesting that the adoption of polymers could happen relatively quickly, particularly as environmental concerns continue to drive the demand for sustainable solutions. Insights from industry experts indicate that polymers could play a pivotal role in the future of aviation, encouraging further research and development to unlock their full potential. The evolution of aviation materials promises to be dynamic, with polymers leading the charge toward a more sustainable and efficient future in air travel.